Pressure differential contact point moving system

A technology of mobile systems and contact points, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve problems such as complex system structures, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

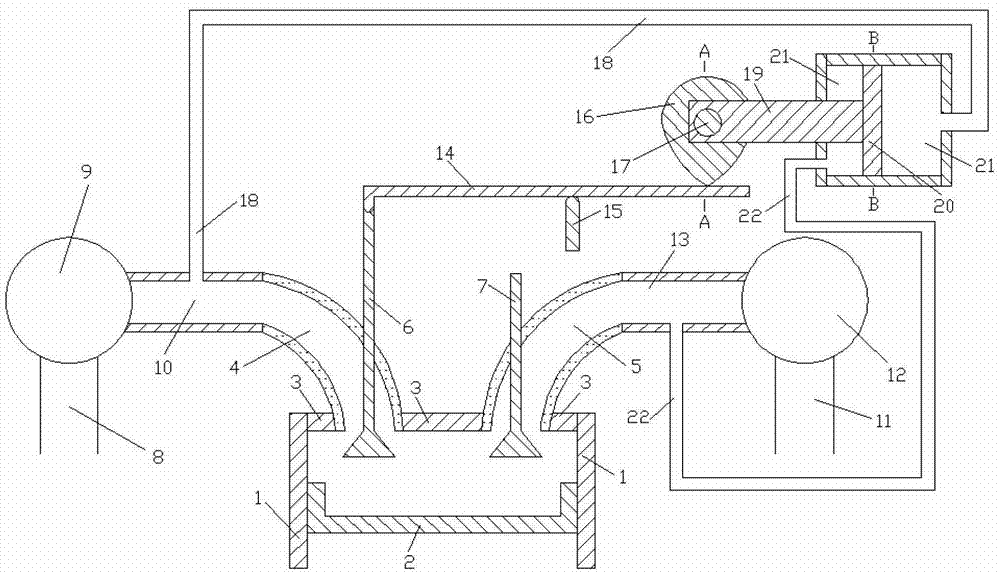

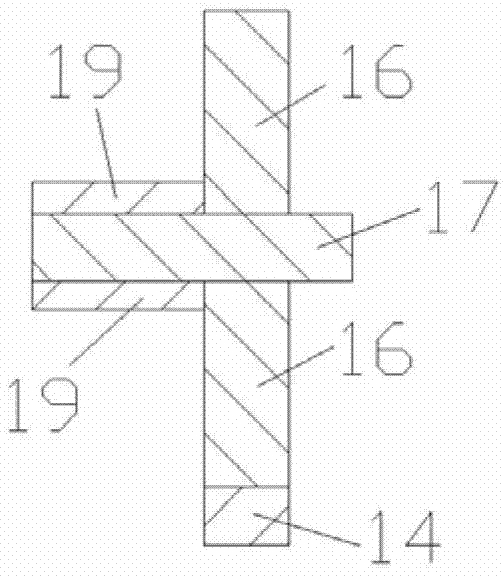

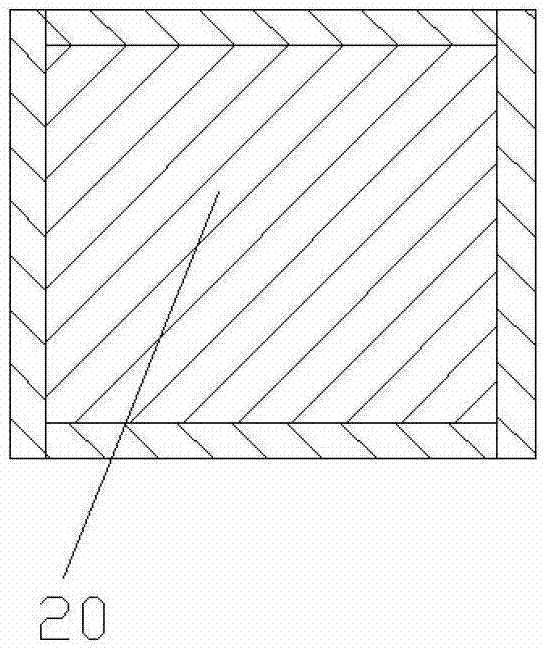

[0015] Such as figure 1 with figure 2 Shown, the present invention comprises: cylinder 1, piston 2, cylinder head 3, air intake passage 4, exhaust passage 5, intake valve 6, exhaust valve 7, air compressor intake pipe 8, air compressor 9, engine air intake pipe 10. Turbine exhaust pipe 11, turbine 12, engine exhaust pipe 13, lever 14, tappet 15, cam 16, camshaft 17, first connecting pipe 18, moving rod 19, moving body 20, volume chamber 21 and the second Two connecting pipes 22, the piston 2 are installed in the space surrounded by the cylinder 1 and are in sealing contact with the inner wall of the cylinder 1, the air outlet of the air inlet passage 4 and the air inlet of the exhaust passage 5 are all connected with the cylinder head, The lower end surface of the intake valve 6 and the lower end surface of the exhaust valve 7 are all in the combustion chamber, and the air inlet and outlet of the compressor 9 are respectively connected with the air outlet of the compressor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com