Method for optimizing additional quality position of curvel vibration type sheet loudspeaker

A technology of additional mass and bending vibration, applied in the direction of sensors, transducer circuits, sensor components, etc., can solve problems such as modal analysis of speakers without thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The concrete steps of the design method of the present invention are specified below in the mode of giving examples:

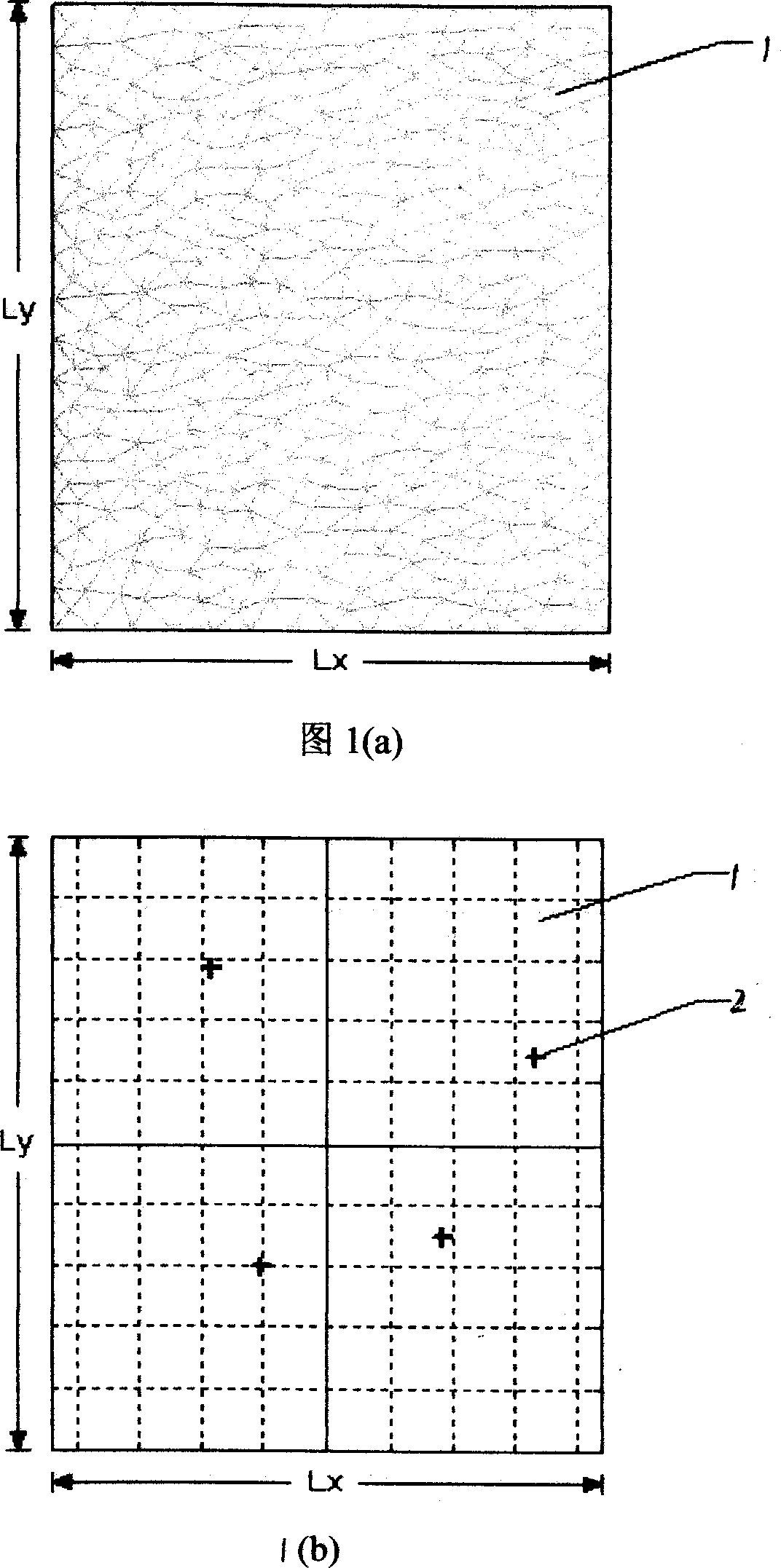

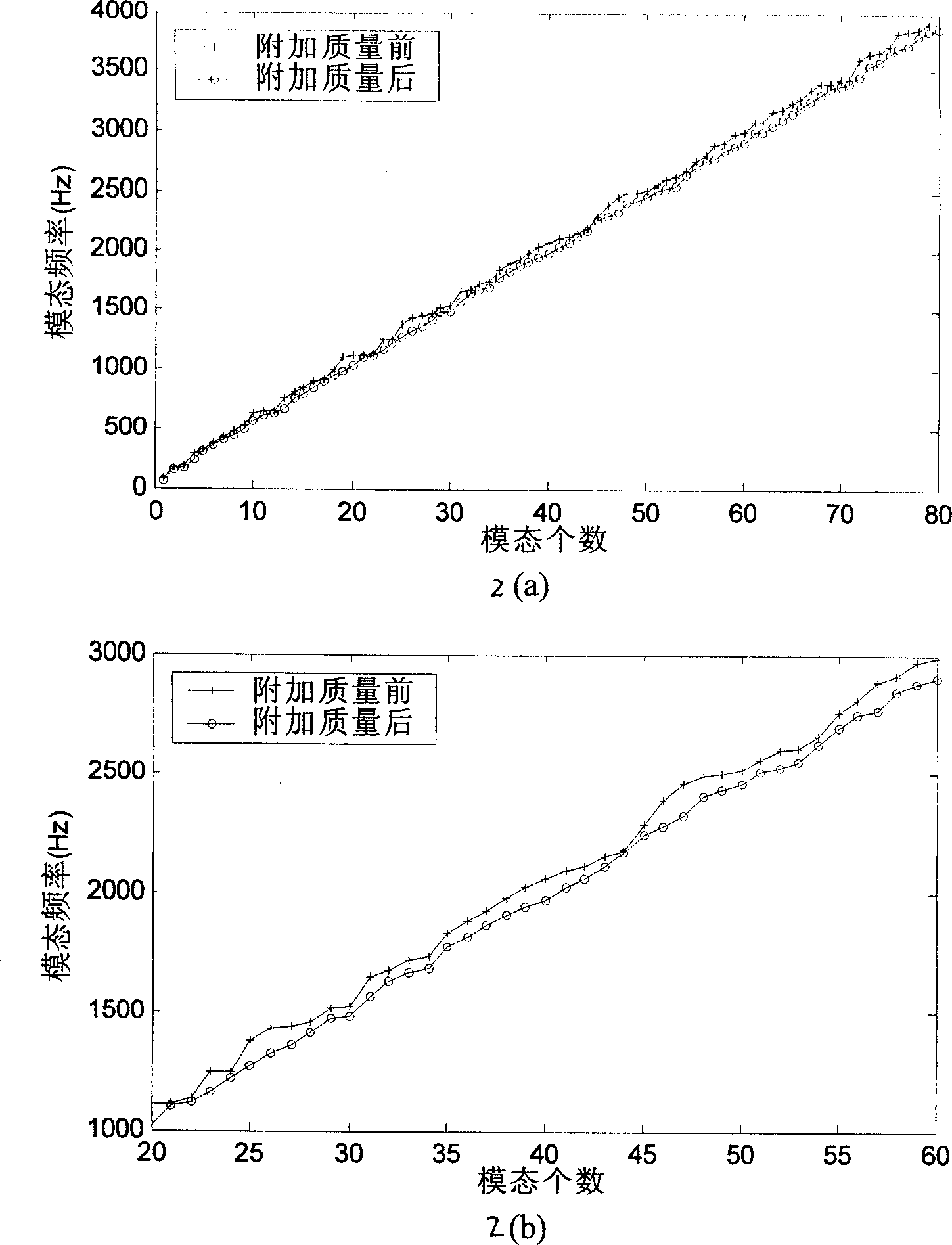

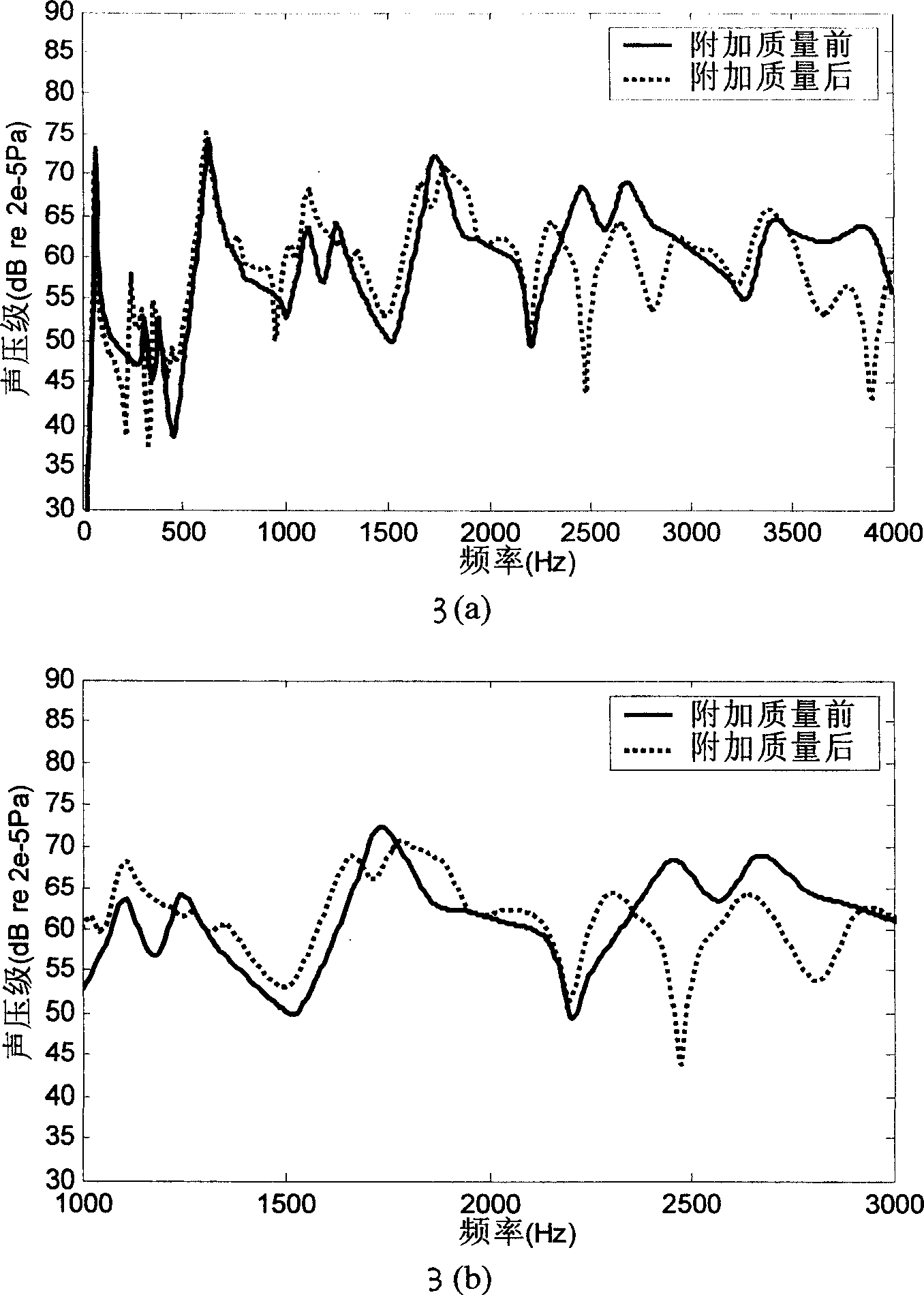

[0053] 1. According to the PDE module of FEMLAB software, the bending vibration model of the thin plate is established. Including defining thin plate parameters and boundary conditions, then meshing the thin plate, and performing modal analysis and steady state analysis respectively to obtain the modal distribution of the thin plate without additional mass and the normal velocity of the thin plate surface vibration, and finally according to the Rayleigh integral The formula calculates the corresponding sound pressure frequency response curve. Respectively as figure 1 (a), figure 2 solid line and image 3 shown by the solid line.

[0054] 2. Define various parameters of the additional mass, and combine the genetic optimization algorithm to obtain the best position of the additional mass when the modal distribution of the thin plate is relatively uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com