An inside liner of ball mill

A ball mill and lining technology, applied in grain processing and other directions, can solve the problem of not finding technical inspiration, and achieve the effects of low grinding efficiency, good wear resistance and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

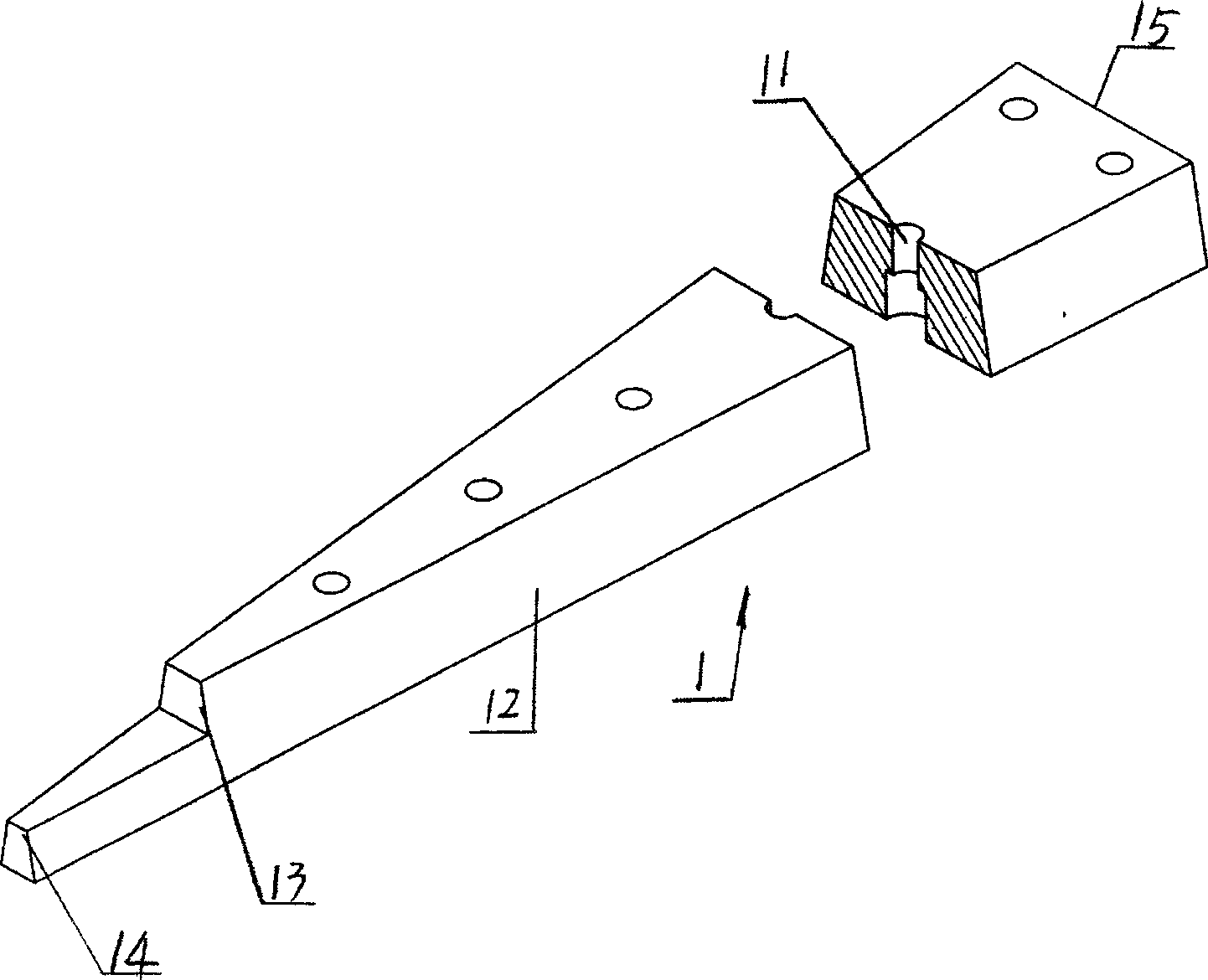

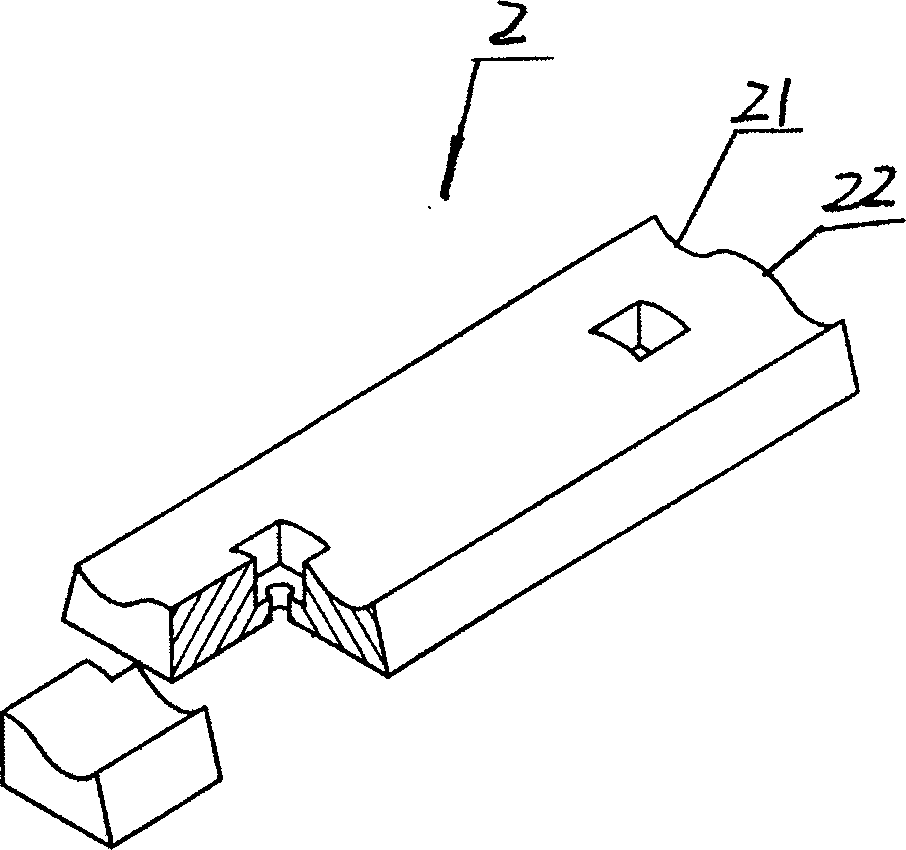

[0013] See figure 1 This figure shows the overall appearance of an embodiment of the trapezoidal plate 1 in the inner lining of the ball mill proposed by the present invention. The trapezoidal plate 1 is made of polyurethane rubber. The trapezoidal plate 1 is provided with a through hole 11 for the insertion of connecting parts such as bolts or screws. The periphery of the trapezoidal plate is provided with a joint composed of an inclined surface 12 or Inwardly shrinking steps (no specific structure is shown in the figure) constitute a joint. The trapezoidal plate 1 is a structure of a slope that gradually becomes thinner from one end to the other end, and a stepped step 13 is provided in the region of the thin end 14 thereof.

[0014] During installation, the thin end 14 and the thick end 15 of two adjacent trapezoidal plates 1 are opposed to each other, and the inclined surface 12 is closely attached to each other, and the connecting piece is used to install it on the inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com