Method for preparing styrene by oxydehydrogenation

A technology for the oxidation of hydrogen to styrene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problem of not meeting the technical requirements of ethylbenzene dehydrogenation reaction, affecting oxidation reaction and dehydrogenation reaction, and adsorption layer Poor potassium removal effect and other problems, to achieve the effect of reducing pressure drop, reducing bed pressure drop, and improving potassium removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

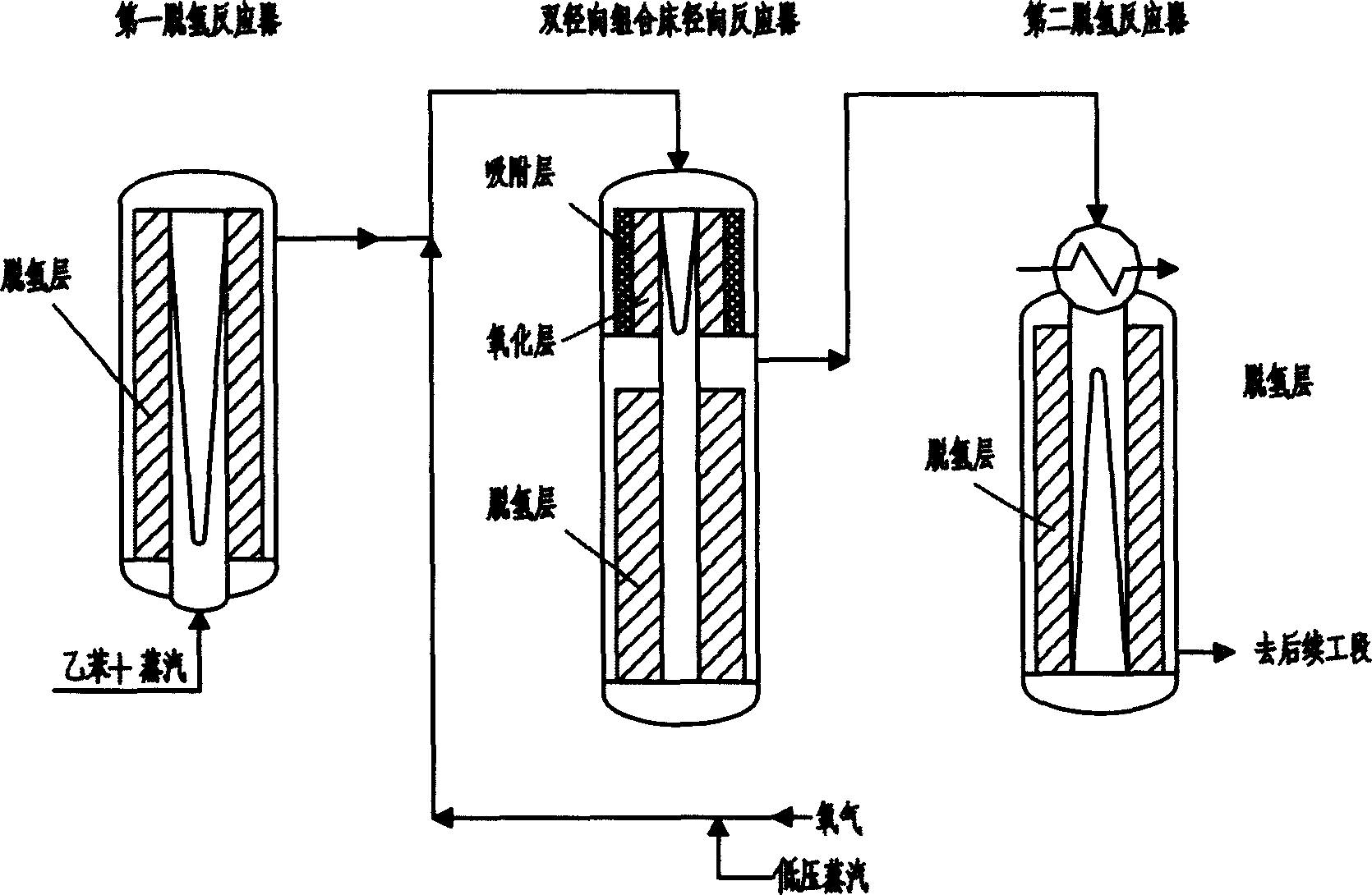

[0026] use figure 1 In the process shown, the water-hydrocarbon ratio (mass ratio) entering the first dehydrogenation reactor is 1.37, and the water-hydrocarbon ratio (mass ratio) entering the oxidative dehydrogenation reactor is 1.65. The inlet temperature of the first dehydrogenation reactor is 620°C, the pressure is 72kPa (absolute pressure), the outlet temperature is 552°C, and the pressure is 68kPa (absolute pressure), and the temperature of the reactant stream is mixed with oxygen-containing low-pressure steam to drop to 510°C , and then enter the oxidative dehydrogenation reactor, first remove potassium through the adsorption layer, and then enter the oxidation layer for hydrogen oxidation reaction, the temperature of the reactant flow out of the oxidation layer reaches 625 ° C, and then enter the lower dehydrogenation layer for reaction, oxidative dehydrogenation reactor The outlet temperature is 578°C and the pressure is 59kPa (absolute pressure). The reactant stream ...

Embodiment 2

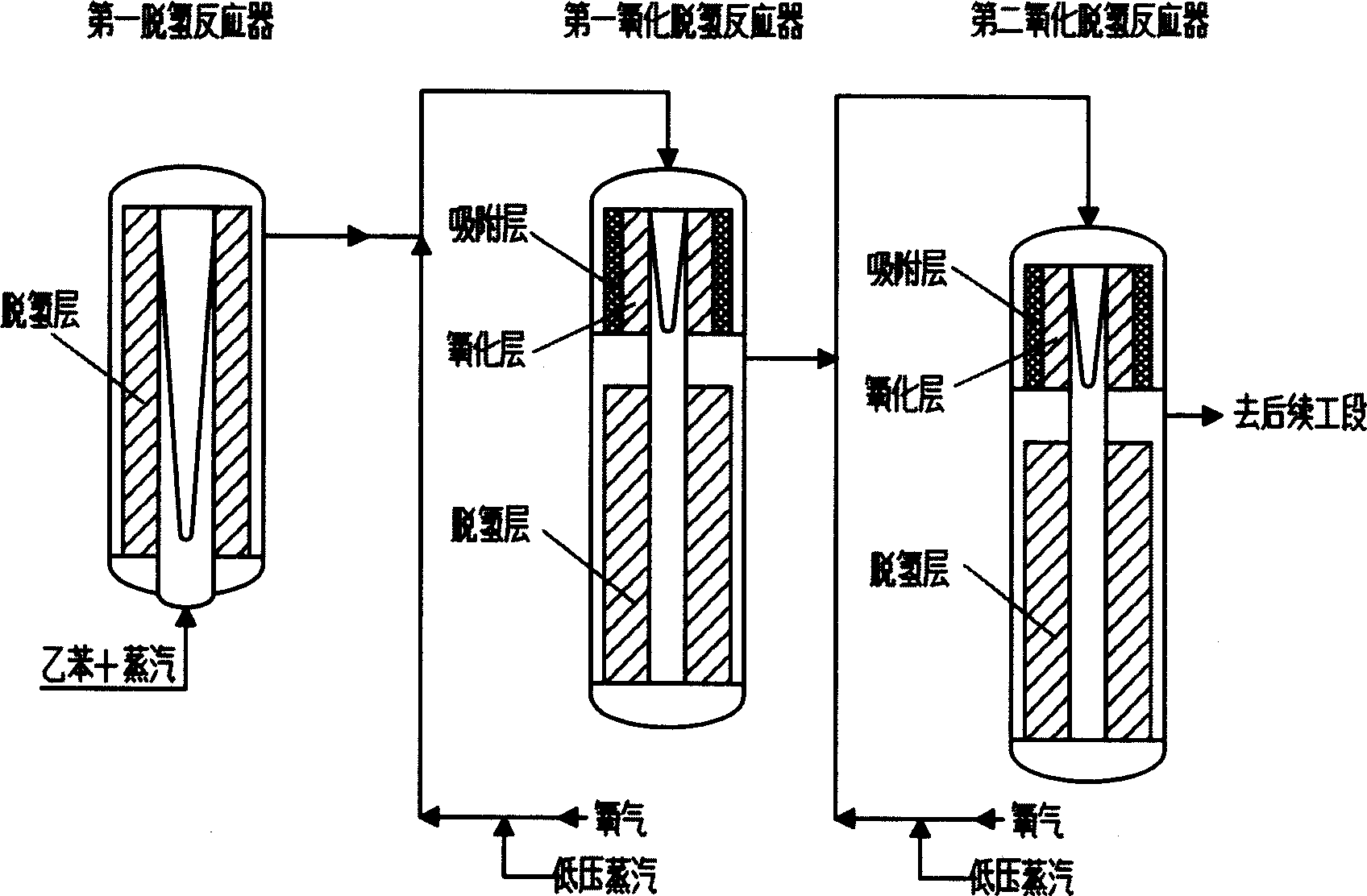

[0029] use image 3 Shown flow process, the water-hydrocarbon ratio (mass ratio) entering the first dehydrogenation reactor is 1.37, the water-hydrocarbon ratio (mass ratio) entering the first oxidative dehydrogenation reactor is 1.65, and the water-hydrocarbon ratio (mass ratio) entering the second oxidative dehydrogenation reactor is 1.65. The water-hydrocarbon ratio (mass ratio) was 1.80. The inlet temperature of the first dehydrogenation reactor is 620°C, the pressure is 72kPa (absolute pressure), the outlet temperature is 552°C, and the pressure is 68kPa (absolute pressure), and the temperature of the reactant stream is mixed with oxygen-containing low-pressure steam to drop to 510°C , then enter the first oxidative dehydrogenation reactor, first remove potassium through the adsorption layer, and then enter the oxidation layer for hydrogen oxidation reaction, the temperature of the reactant flow out of the oxidation layer reaches 625 ° C, and then enter the lower dehydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com