Anti-rotation quick connector

一种连接器组件、快速的技术,应用在套筒/插座连接、联轴器、管接头等方向,能够解决螺纹尺寸昂贵、增加材料、增加加工时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

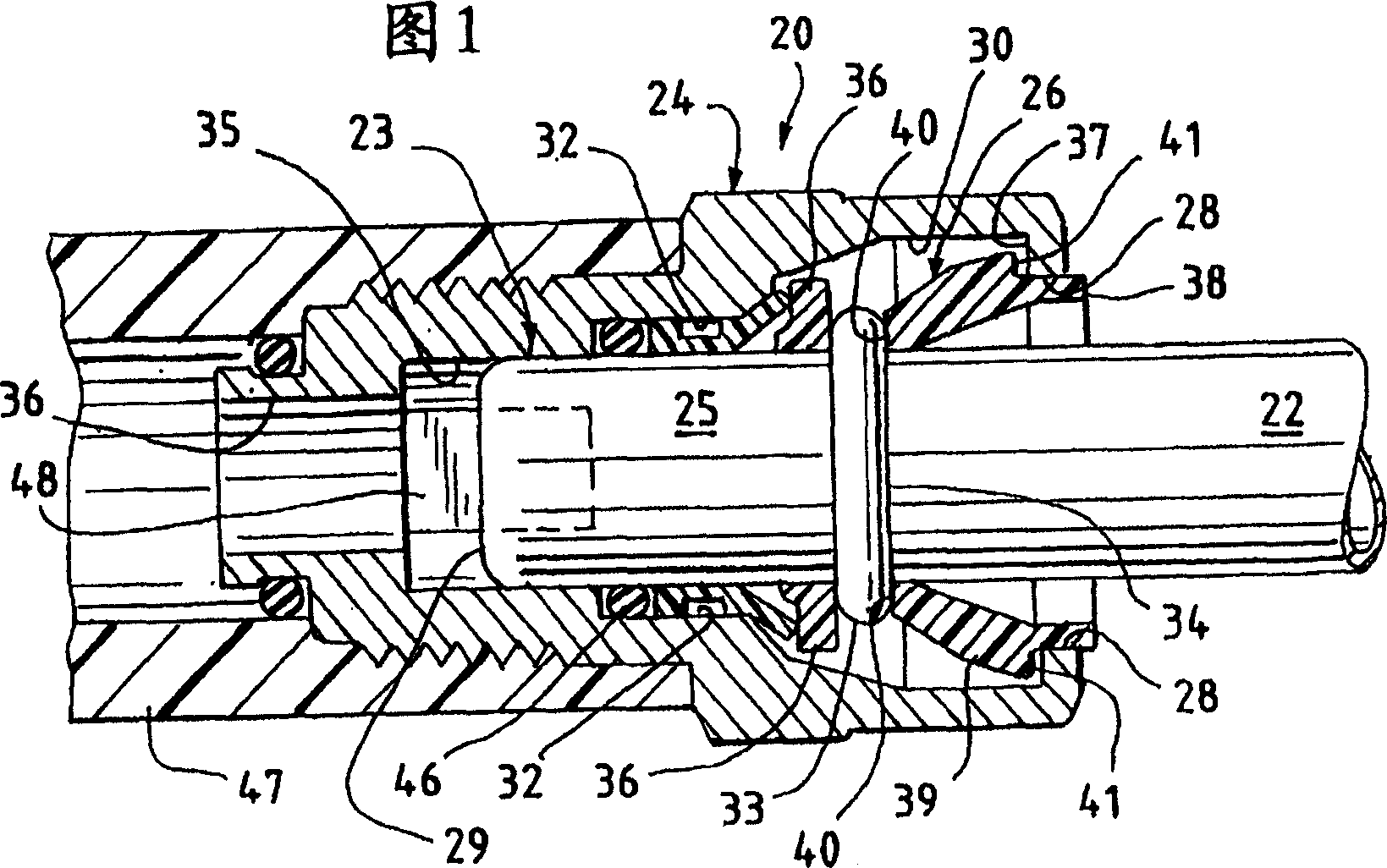

[0033] Figure 1 shows a cross-sectional view of a quick connector assembly, generally indicated at 20, embodying the teachings of the present invention. It includes a fluid fitting 22 and a body or housing 24 . A retainer 26 provides a releasable connection between the fluid system tubing 22 and the body 24 . The main body 24 is connected to a flexible hose 47 which connects the rest of the fluid system. This connector connection is generally similar to the quick connector disclosed in US Patent 5,161,832, which is hereby incorporated by reference.

[0034] The invention is suitable for various fast connector connection devices. Patents 5,257,833, 5,324,082, 5,395,140, 5,449,848, 5,628,531 and 6,086,118 are examples of quick connectors suitable for use with the present invention. It is envisioned that the present invention may also be used with various other known quick connector connection arrangements.

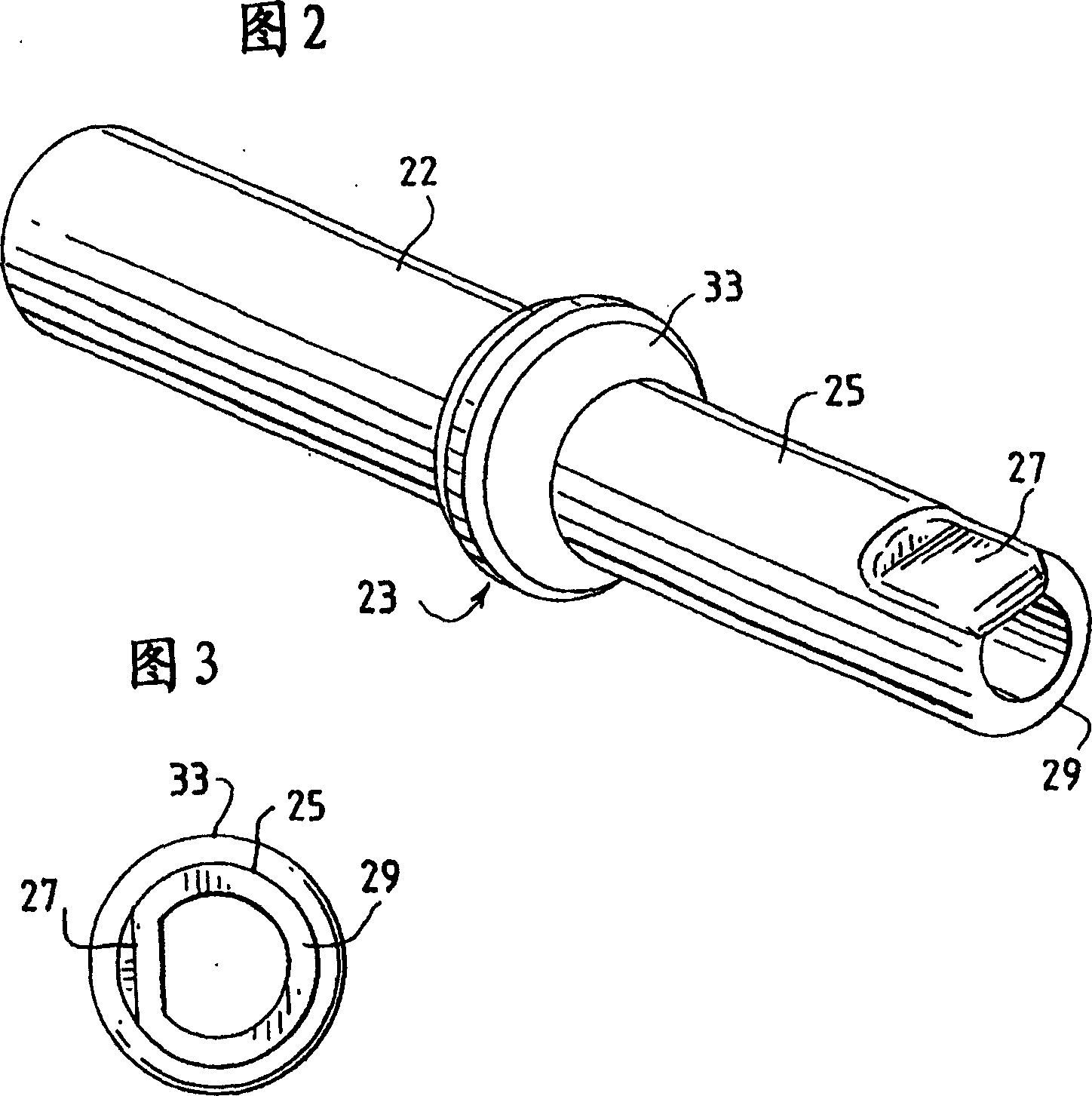

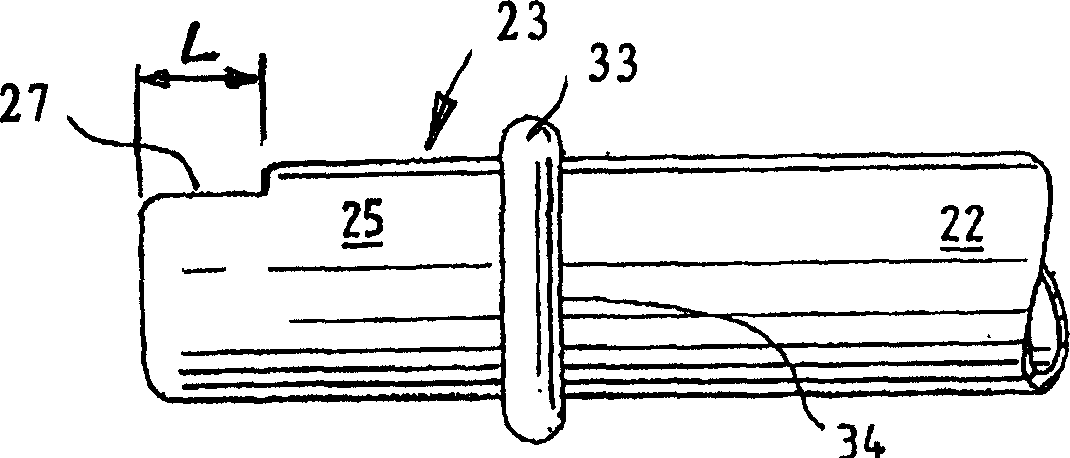

[0035] Tube 22 is a rigid metal tube. It comprises an end region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com