Fuel cell stack packaging device

A fuel cell stack and packaging device technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of stack leakage, dust or water erosion of the stack, and no hydrogen leakage safety protection device, etc., to prevent explosions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

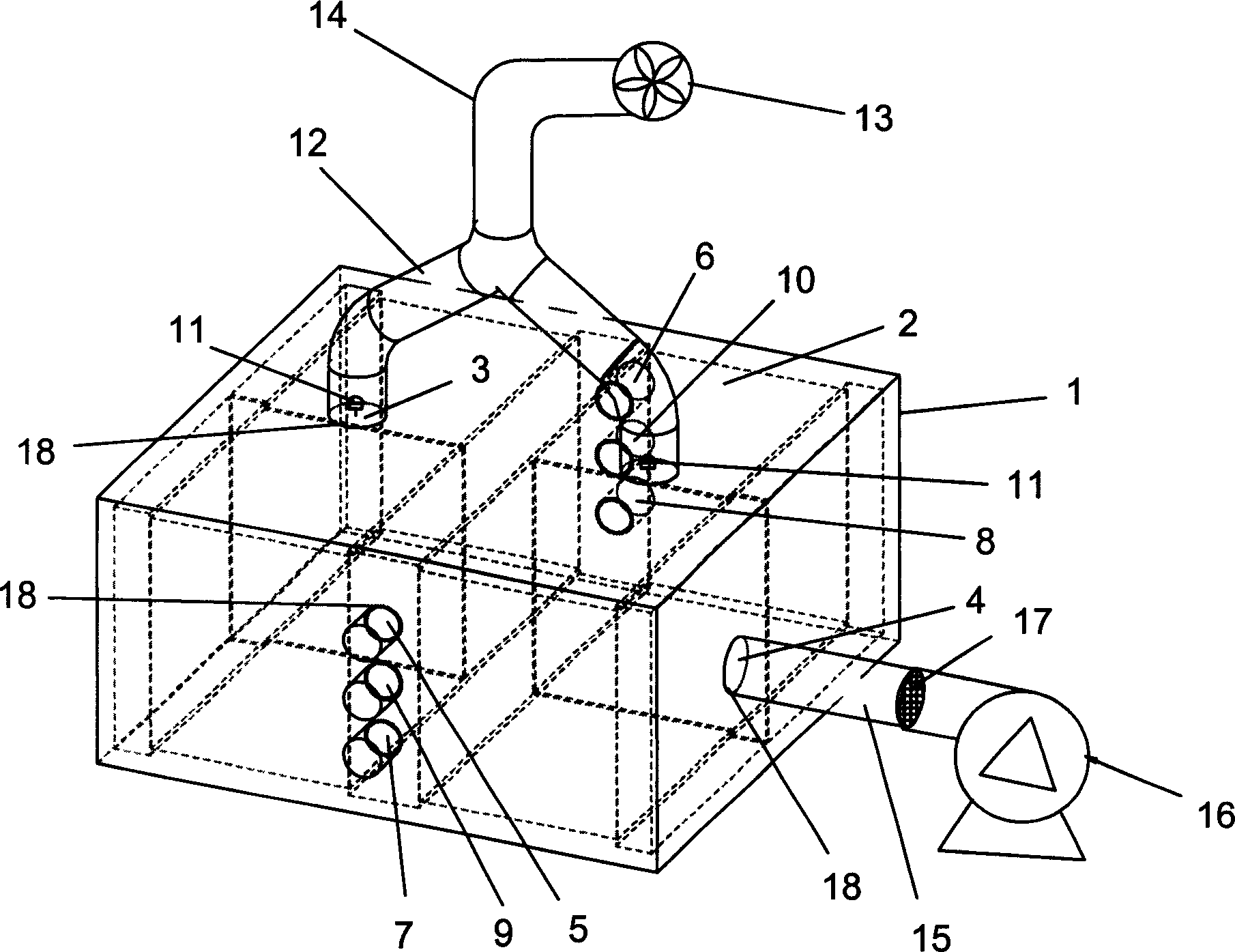

[0022] The present invention will be further described below in conjunction with the drawings.

[0023] Such as figure 1 As shown, a packaging device for a fuel cell stack includes a closed packaging frame 1, which encapsulates all components of the fuel cell integrated stack 2, and the packaging frame 1 is provided with exhaust Port 3, vent 4, and air pipe inlet 5, air pipe outlet 6, hydrogen pipe inlet 7, hydrogen pipe outlet 8, cooling water pipe inlet 9, and cooling water pipe outlet 10 corresponding to the fluid inlet and outlet pipes of the stack; The exhaust port 3 is provided with a hydrogen detector 11, the exhaust port 3 extends outwards with an exhaust pipe 12, and an exhaust fan 13 is provided on the exhaust pipe. There are two exhaust pipes 12, these exhaust The air ducts 12 finally converge into a general exhaust duct 14. The exhaust fan 13 is arranged at the end of the general exhaust duct 14; the vent 4 extends outwards with a ventilation duct 15 on which a blower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com