Field electrochemical contact angle investigating method based on micronano interface

A measurement method and contact angle technology, applied in the field of chemical measurement, can solve the problems of not being able to quantitatively analyze the time-to-time changes of the sample to be tested, and not being able to record dynamically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

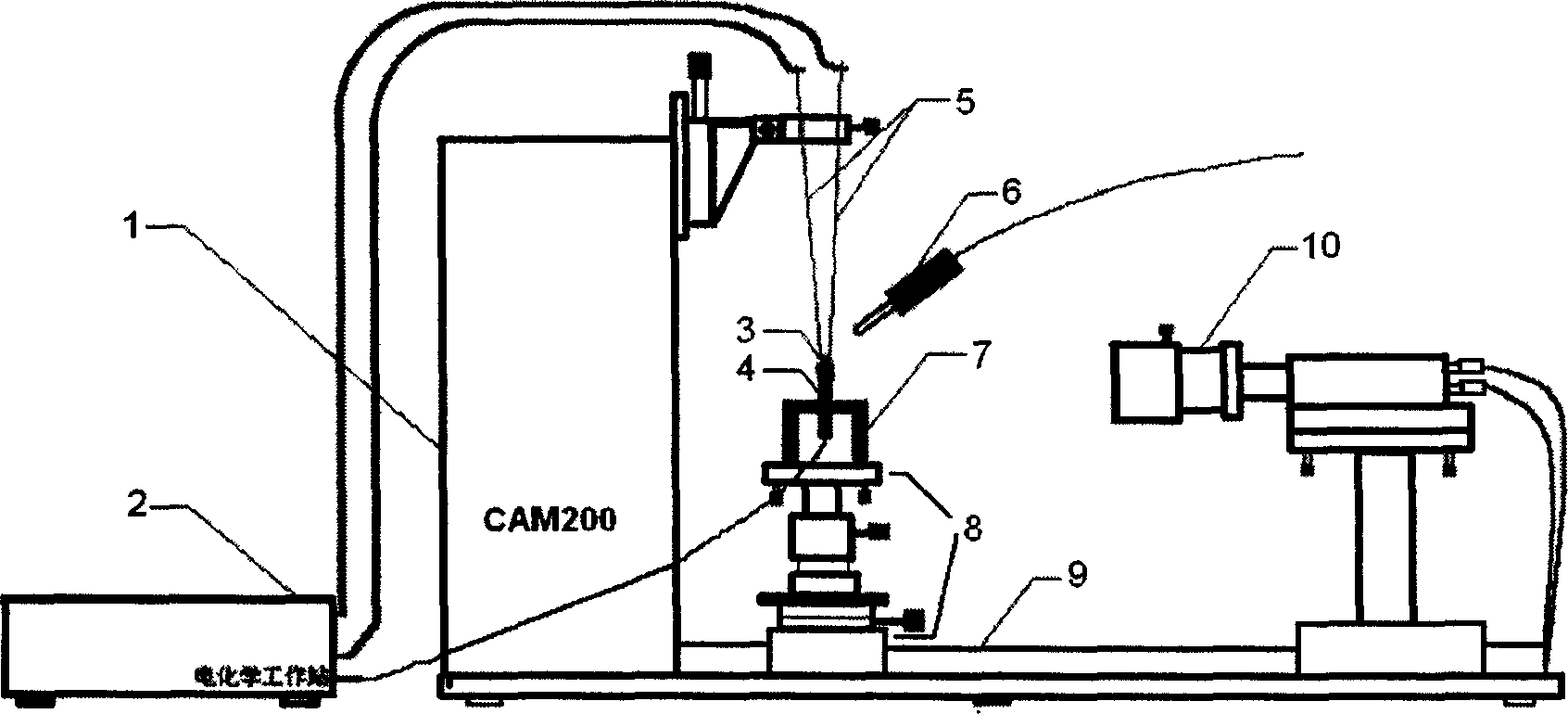

[0024]1. Silver wire is used as the reference electrode, platinum wire is used as the counter electrode, and glassy carbon electrode is used as the working electrode. First, measure the potassium ferricyanide standard solution with three pairs of electrodes to test whether the electrochemical performance of the electrodes meets the requirements.

[0025] 2. After the test is normal, fix the working electrode to the platform of the contact angle measuring instrument, keep its top level, add the sample to be tested to the working platform, and then move horizontally or vertically to adjust the position of the electrode to the best.

[0026] 3. Lead out the silver wire (reference electrode) and platinum wire (counter electrode), connect them to the droplet of the sample on the contact angle measurement platform, and put the two electrodes into the capillary glass tube, so that the electrodes can be easily stabilized shape, which controls electrode position.

[0027] 4. Turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com