Method for extracting 2 - ethyl hexenal in polyvinyl butyral acetal, and measuring content

A technology of polyvinyl butyral resin and ethyl hexenal, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of difficult PVB resin control and content determination, difficult separation and determination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

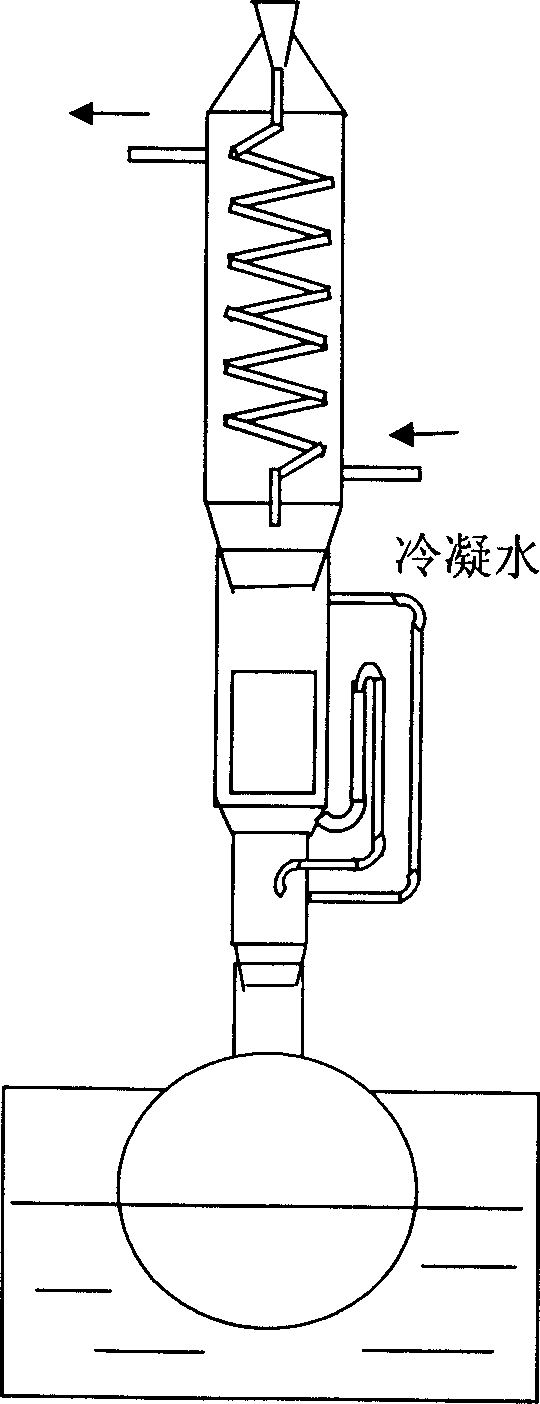

Method used

Image

Examples

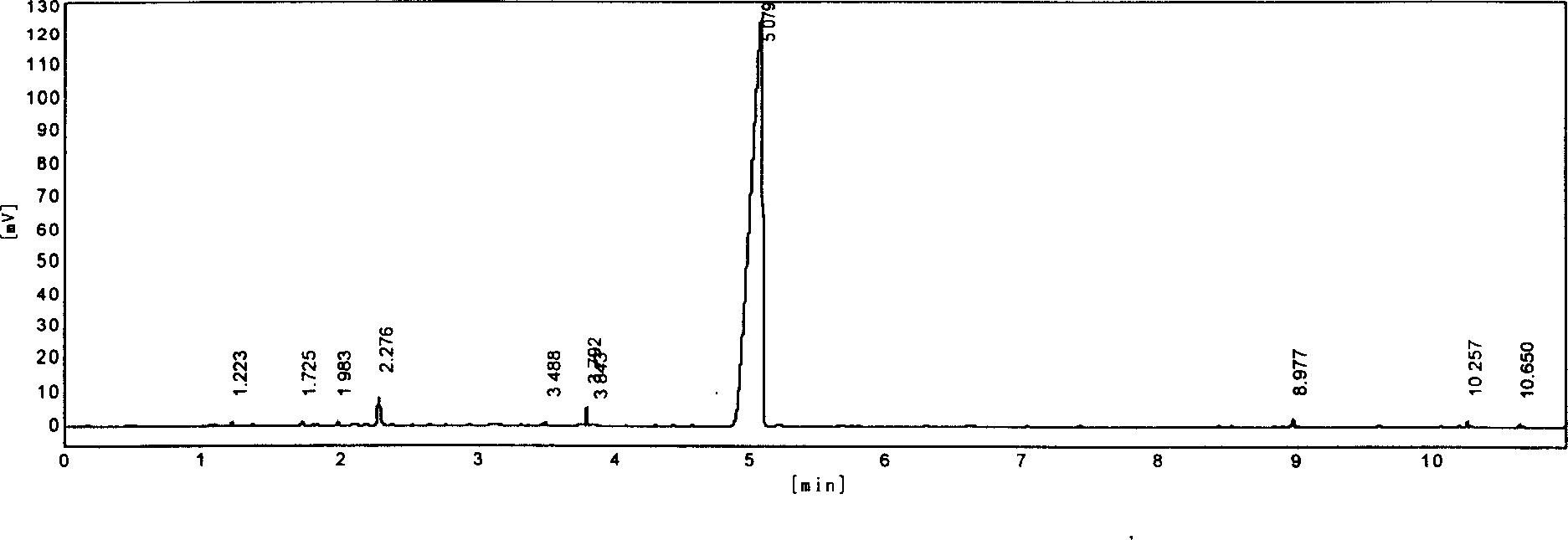

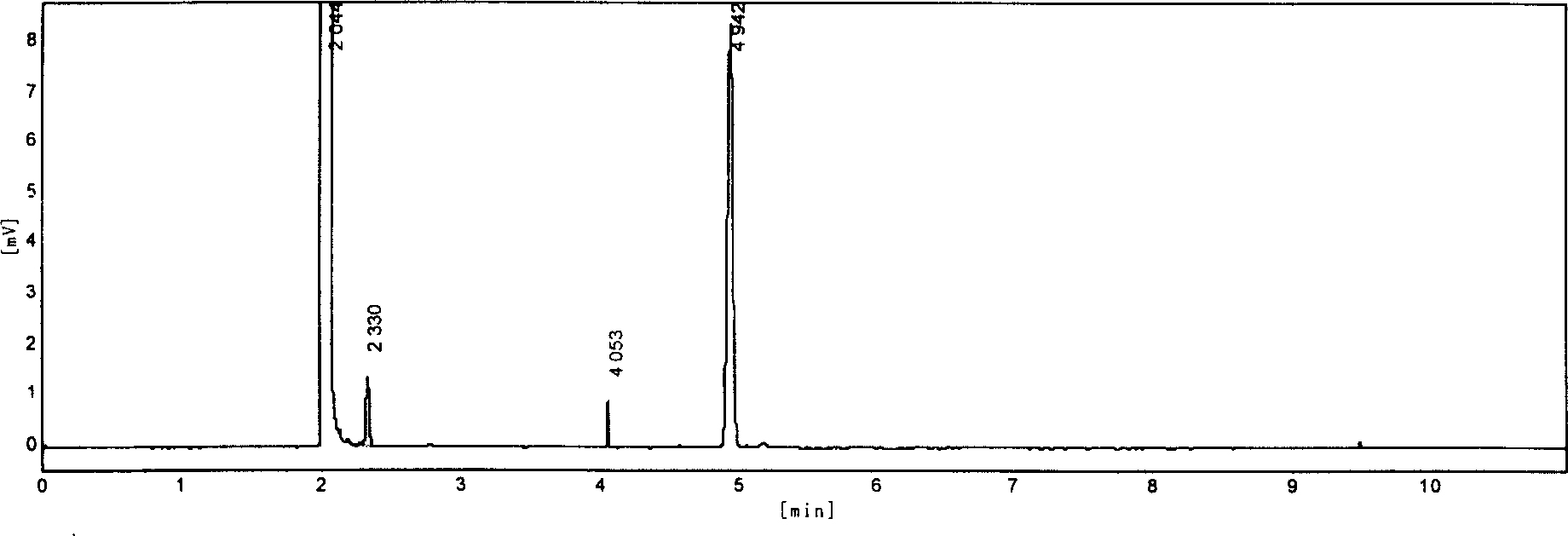

Embodiment 1

[0103] Embodiment 1: Get the PVB resin of Germany WACKER company that particle diameter is 20~400 μm, trade mark: LL4190 batch number is: 5112124, test according to the above-mentioned steps, record the concentration wt% of ET2H in the sample and be 0.018%.

Embodiment 2

[0104] Embodiment 2: Get the PVB resin for film of American DuPont Company whose particle size is 80~400 μm, batch number: 20040315, carry out test according to the above-mentioned steps, record the concentration wt% of ET2H in the sample to be 0.006%.

Embodiment 3

[0105] Example 3: Take Tianjin Yanhua New Material Co., Ltd. PVB resin for film with a particle size of 50-300 μm, batch number: 050214, and test according to the above steps, and the concentration wt% of ET2H in the sample is found to be 0.023%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com