Lyophilized powder injection of cepharantine hydrochloride and preparation method thereof

A technology of stephine hydrochloride and freeze-dried powder injection, which is applied in the field of stephine hydrochloride freeze-dried powder injection and its preparation, which can solve the problems of reduced drug clarity, inconvenient transportation and storage, and reduced storage content, and achieves the convenience of room temperature storage , extended validity period, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

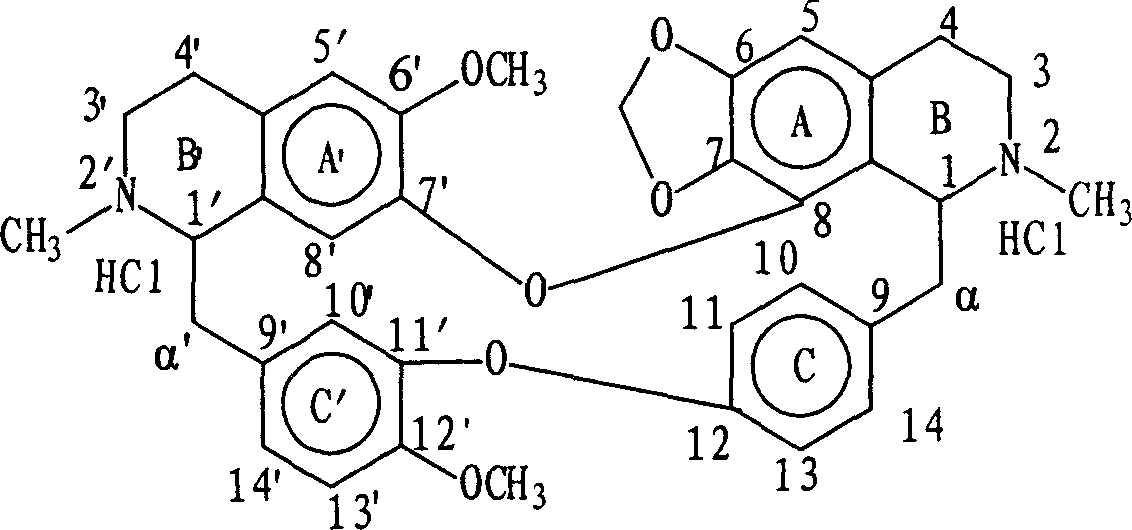

Image

Examples

Embodiment 1

[0016] Take 1.1 grams of stephanine hydrochloride (pure) raw material for injection (purity 99%), add 1000 ml of water for injection (50 ° C), stir and dissolve, add 10 grams of mannitol, stir to dissolve, and filter through a 0.22 μm microporous membrane Sterilize, test that the content of stephanine hydrochloride (vegetable) reaches more than 99% of the marked amount, then pack in 2ml / bottle. Freeze-drying is carried out, and the freeze-drying conditions are a freeze-drying temperature of -20 to -35° C., a vacuum of 50 to 200 Pa, and a time of 24 hours. Then out of the box, sealing, leak detection, labeling. All are carried out in workshops meeting GMP requirements. Dosage: Intravenous infusion of 50mg / time, once a day. Usage: Shake and dissolve with 2ml of water for injection, add 250ml of normal saline or 5% glucose injection, and infuse intravenously.

Embodiment 2

[0018] Take 5 grams of stephine hydrochloride (pure) raw material for injection (purity 99%), add 900 ml of water for injection (60 ° C), stir to dissolve, add 100 grams of trehalose, stir to dissolve, add water to 2000 ml, and use 0.20 μm micro Sterilize by filtering through a pore filter membrane, measure the content of stephanine hydrochloride to reach more than 99% of the marked amount, then sub-package, 2ml / bottle, and freeze-dry. The freeze-drying condition is a freeze-drying temperature of -20 to -35°C, a vacuum of 50 to 200Pa, and a time of 32 hours. Then out of the box, sealing or capping, leak detection or capping, and labeling. All are carried out in workshops meeting GMP requirements. Dosage: Intravenous infusion of 50mg / time, once a day. Usage: Shake and dissolve with 2ml of water for injection, add to 250ml of 5% glucose injection, and inject intravenously.

Embodiment 3

[0020] Take 10 grams (purity 99%) of stephanine hydrochloride (purity) raw material for injection, add 3600ml of water for injection (55°C), stir to dissolve, add 400 grams of glucose, stir to dissolve, add water to 4000ml, and use 0.25μm micropore Sterilize by membrane filtration, measure the content of stephanine hydrochloride to reach 99% to 100% of the labeled amount, and carry out sub-packaging. Then freeze-dry for 36 hours at a temperature of -20 to -35°C and a vacuum of 50 to 200 Pa, take it out of the box, press the cap, crimp the cap, and stick a label. All are carried out in workshops meeting GMP requirements. Dosage: Intravenous infusion of 50mg / time, once a day. Usage: Shake and dissolve with 2ml of water for injection, add to 250ml of normal saline, and infuse intravenously.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap