A roll as well as a ring for such a roll

A roll and roll ring technology, applied in the field of rolls and rings used for such rolls, can solve the problems of failure, fatigue, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

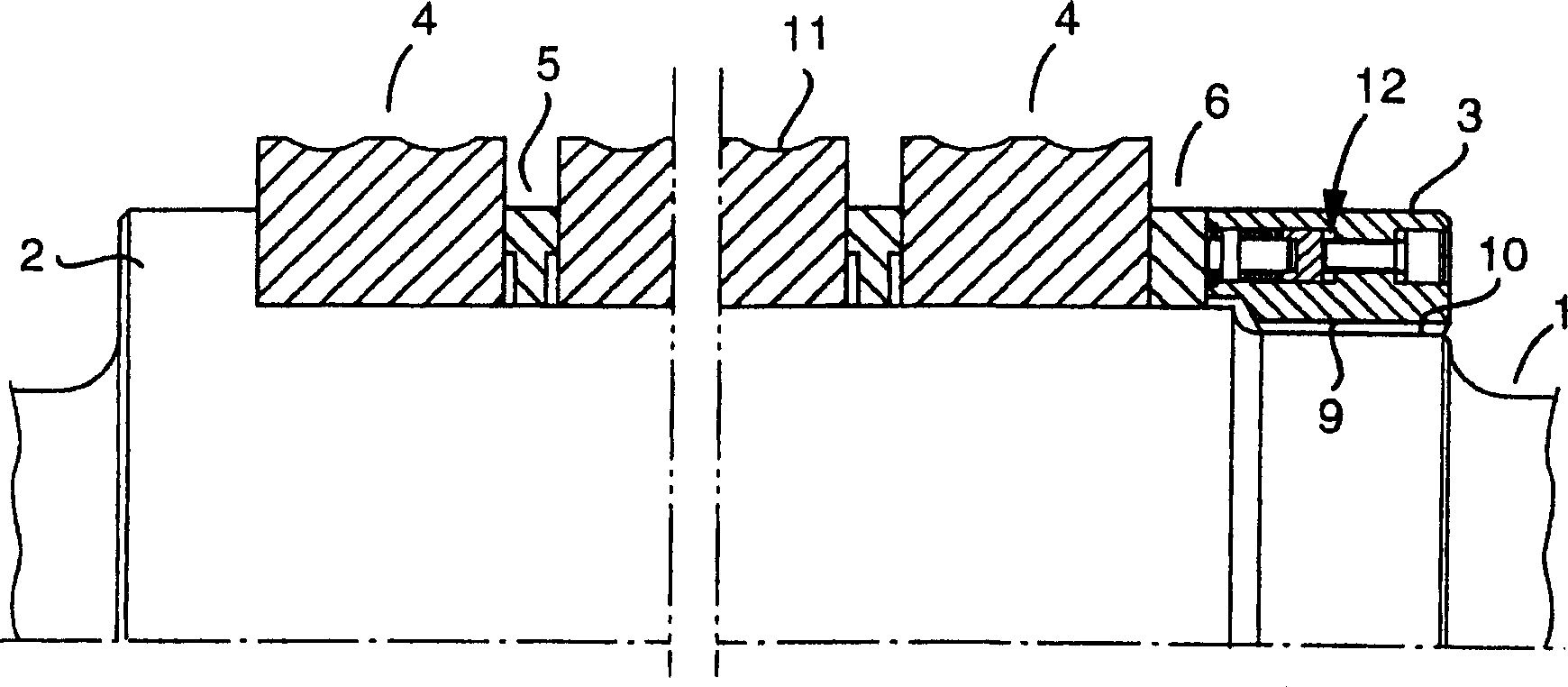

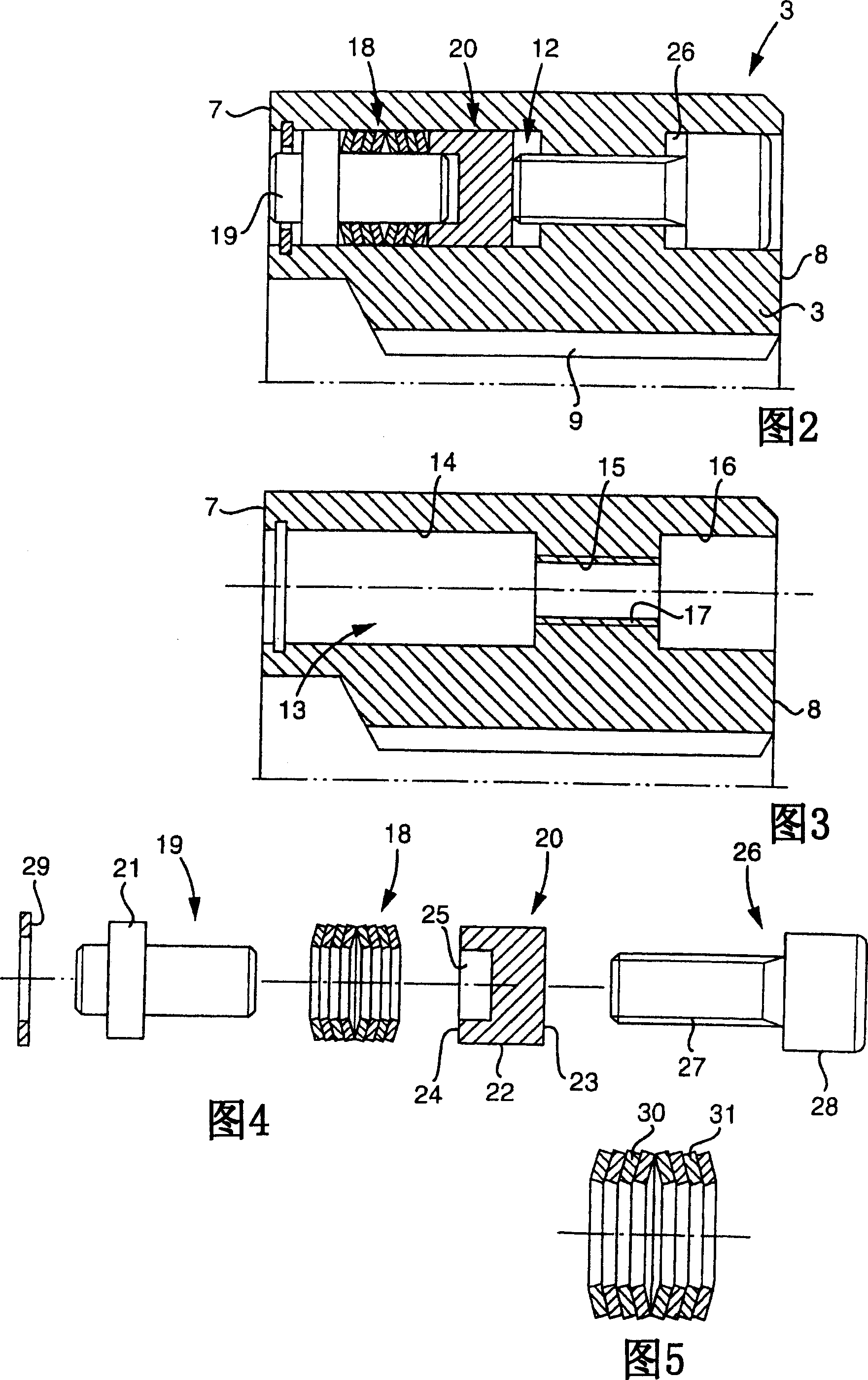

[0015] figure 1 shows a composite roll comprising, in the conventional manner, a drivable shaft or roll shaft 1 with two axially spaced apart stop rings 2, 3, one of which, stop ring 2, is fixed, And the other is detachable from the lock nut 3 on the shaft. In this example, the fixed stop ring 2 is in the form of an annular shoulder integrally formed with the remainder of the shaft. However, it is also feasible to manufacture the fixed stop ring 2 in the form of a separate detachable ring, which is axially locked relative to the shaft in a suitable manner.

[0016] A plurality of detachable rings, some of which are roller rings 4 and others of which are spacer rings 5 , are arranged between the fixed stop ring 2 and the separable jam nut 3 . Between the lock nut 3 and the roller ring 4 located closest to it there is an additional ring 6 , the design of which may differ from that of the spacer ring 5 and which is hereinafter referred to as the fastening ring. In general, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com