Crank bearing unit

A bearing and needle bearing technology, applied in bearing components, bearings, roller bearings, etc., can solve the problems of small bearing capacity, can not be assembled, no longer provide no gap, etc., and achieve high bearing capacity, simple assembly and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

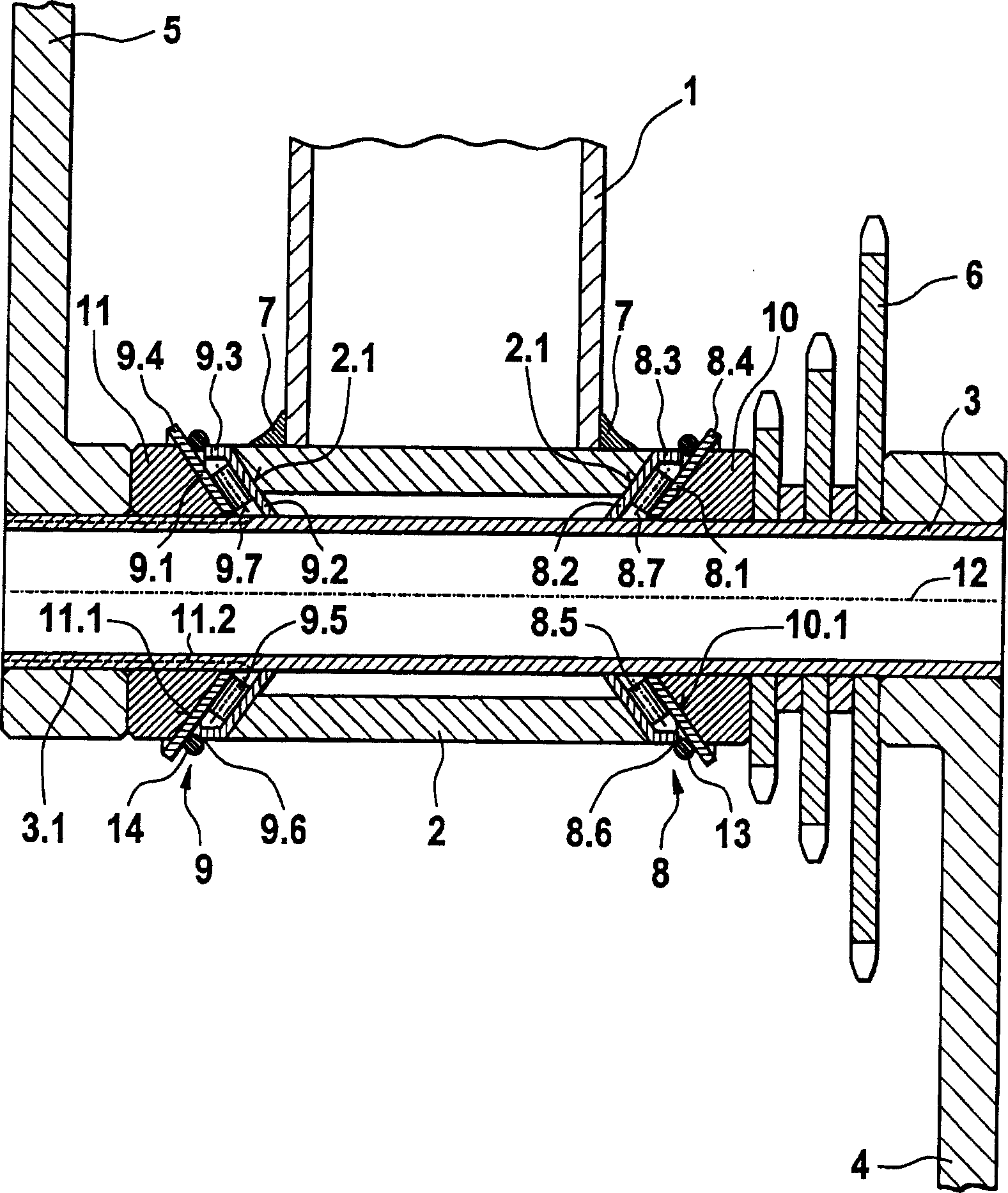

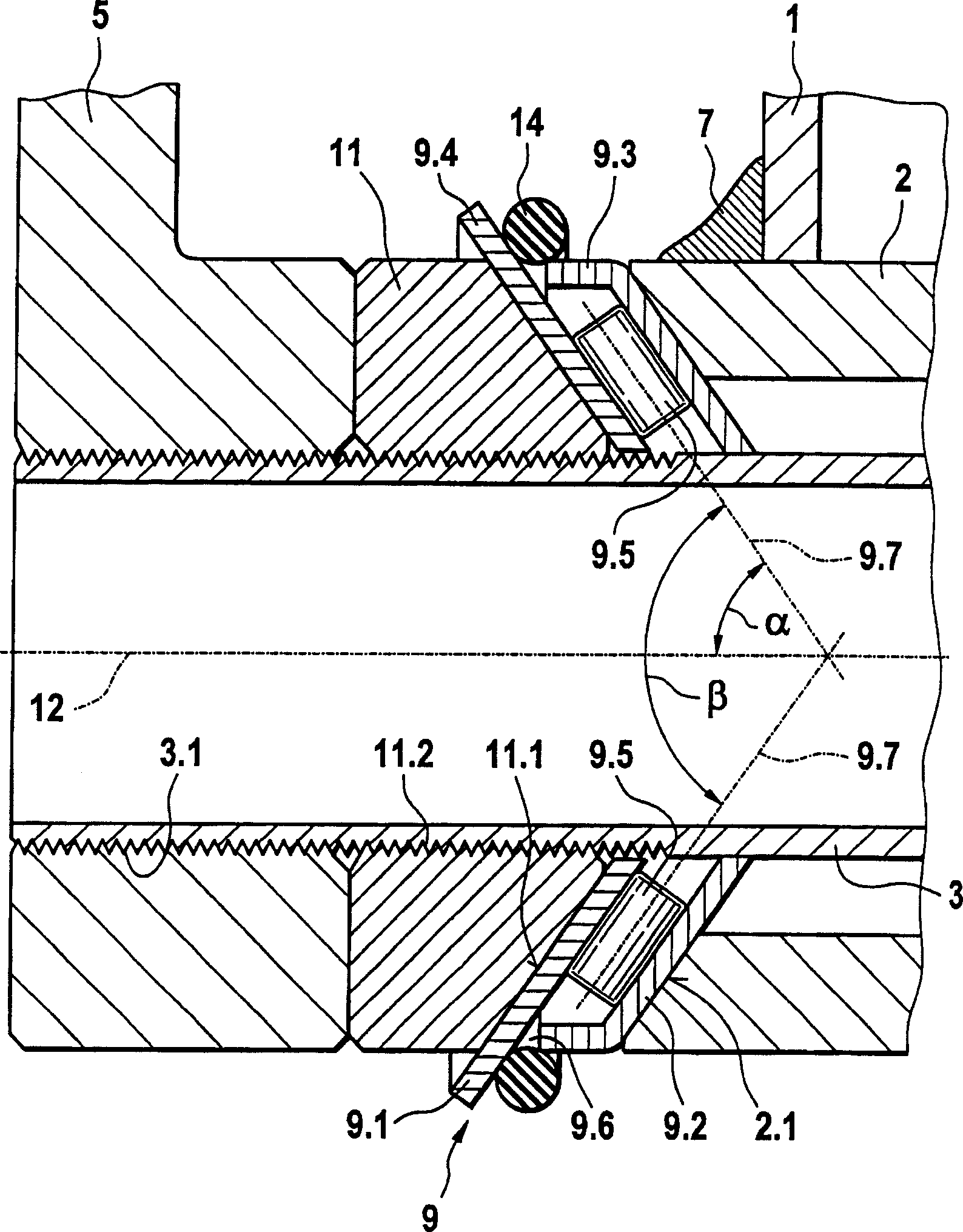

[0021] exist figure 1 and 2 The pedal bearing unit for a bicycle shown schematically in , consists of a pedal bearing shaft 3 configured as a hollow shaft, which is connected on both sides to the pedals 4 and 5 and is accommodated by the pedal bearing housing 2 , the pedal bearing shell is connected with the vehicle frame 1 through the welding seam 7 again. The rotatable accommodation of the pedal bearing shaft 3 in the housing 2 takes place via two axially inclined needle bearings 8 , 9 spaced apart from one another in the axial direction. The two needle roller bearings have needle rollers 8.5, 9.5 whose axes of rotation 8.7, 9.7 are arranged obliquely at an angle α to the bearing axis 12, wherein the needle rollers 8.5, 9.5 can be arranged in a cage, which is shown in the figure not shown. The outer turntables 8.1, 9.1 and the inner turntables 8.2, 9.2 belong to each bearing 8, 9, and these turntables rest on conical bearing surfaces 2.1, 10.1, 11.1, which are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com