Moisture-curing polyurethane material having a long gel time

A polyurethane adhesive and adhesive technology, applied in the field of polyurethane adhesives, can solve problems such as uncomfortable construction and high vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

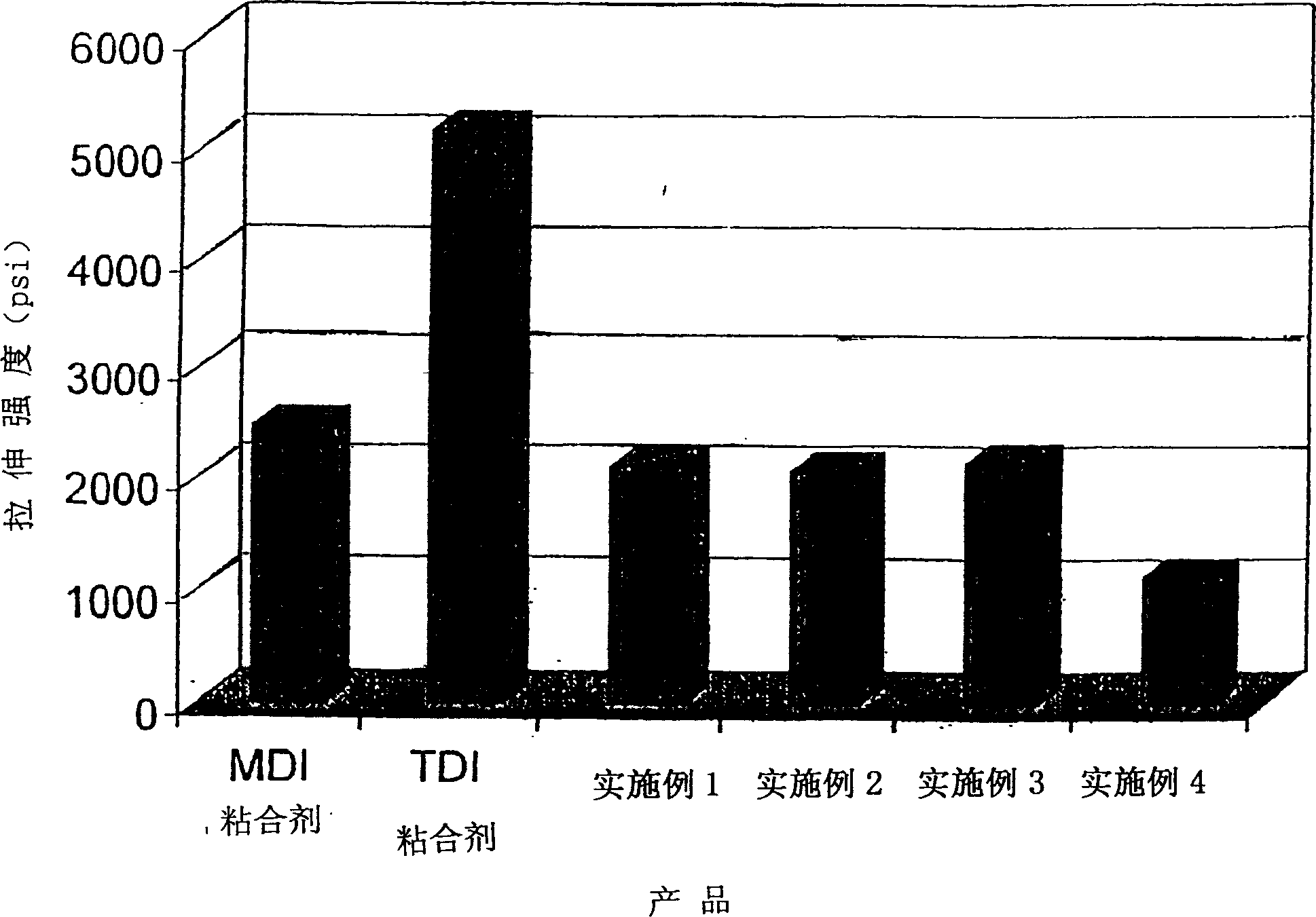

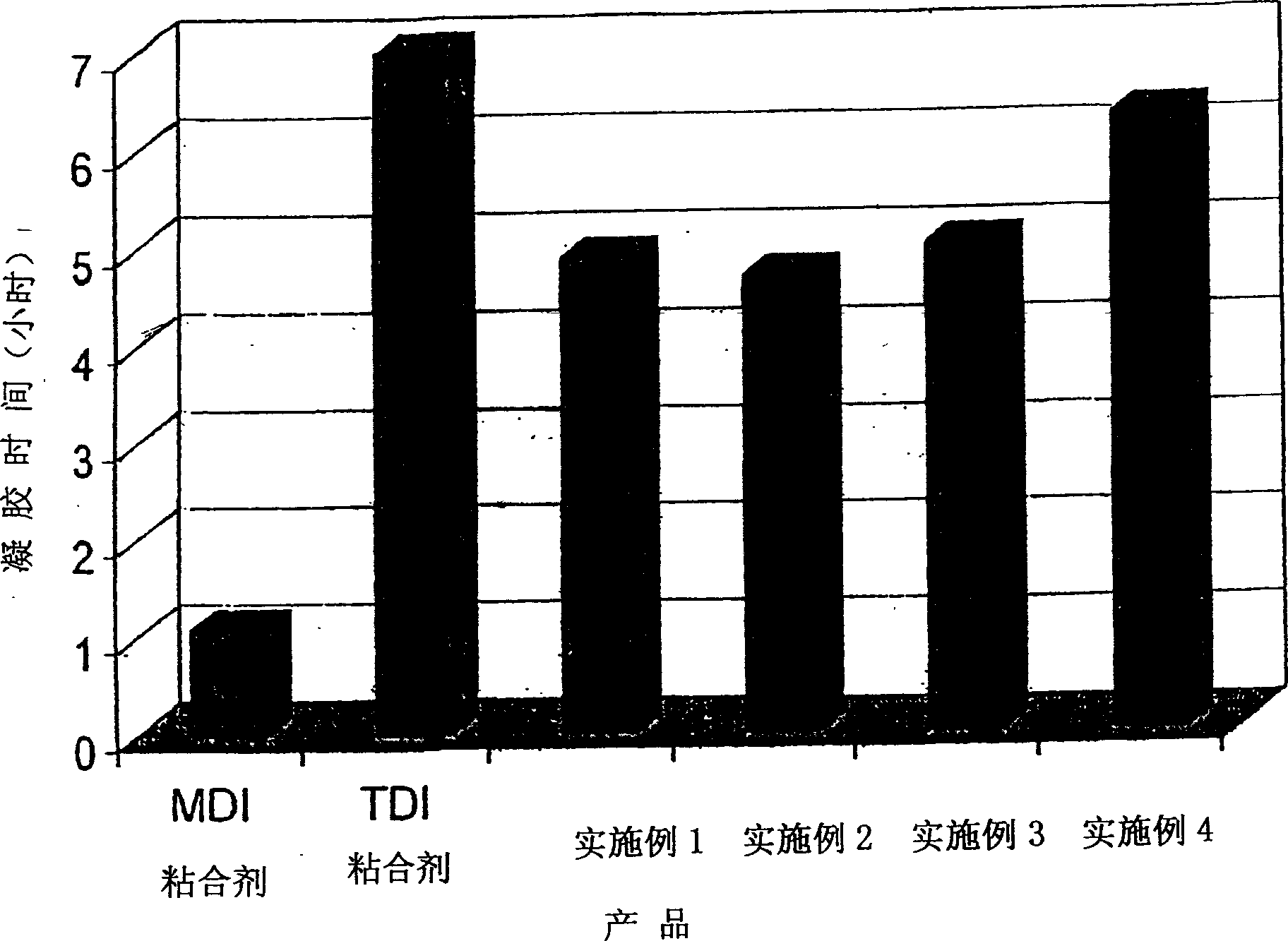

[0024] The adhesive is mixed with recycled rubber powder to make an elastic surface material. The adhesive is prepared as follows: Mix 698 parts by weight (eg, grams) of polyether polyol (a diol with a molecular weight of 4000, Shell's PPG-4000) , 7 parts by weight of two (propylene glycol), 295 parts by weight of diphenylmethane diisocyanate (4,4'- and 2,4'-diphenylmethane diisocyanate 50 / 50 mixture). Adhesive was stirred at 80°C for 2 hours to form a colorless oily polyurethane prepolymer. The resulting prepolymer adhesive contained 8% by weight of isocyano (NCO) and had a viscosity of 2700cP at 27°C. The gel time was 4.9 hours under the conditions of dew point and 77% humidity. The adhesive had a cured sheet tensile strength of 2121 psi and an elongation at break of 622%.

[0025] Prepare a mixture of 200 grams of prepolymer binder and 800 grams of recycled rubber powder with a particle size of 1-3mm, stir the mixture so that the recycled rubber powder is completely wetted...

Embodiment 2

[0027] 7 parts by weight of bis(propylene glycol) were mixed with 295 parts by weight of diphenylmethane diisocyanate (50 / 50 mixture of 4,4'- and 2,4'-diphenylmethane diisocyanate). Stir at 35-55°C for 1 hour, then add 698 parts by weight of polyether polyol (a diol with a molecular weight of 4000, Shell's PPG-4000), and stir for another 2 hours at 80°C to obtain The polyurethane adhesive contains 8% by weight of isocyano (NCO), the viscosity at 26°C is 2800cP, and the gel time is 4.7 hours at 25°C, 22°C dew point, and 84% humidity. The cured sheet of the polyurethane adhesive has a tensile strength of 2080 psi and an elongation at break of 630%.

[0028] Prepare a mixture consisting of 200 grams of polyurethane adhesive and 800 grams of recycled rubber powder with a particle size of 1-3mm, stir the mixture so that the recycled rubber powder is completely wetted by the adhesive, and then pour half of it into 48× In a 30×2cm pan, use a roller to press it into a 9.5-10.5cm unif...

Embodiment 3

[0030] Adhesive is obtained as follows: the diphenylmethane diisocyanate (4, 4, 4'- and 2,4'-diphenylmethane diisocyanate 50 / 50 mixture). The mixture was stirred at 80° C. for 2 hours, cooled to 65° C., then added with 7 parts by weight of di(propylene glycol), stirred at 40-65° C. for 1 hour, and the obtained polyurethane adhesive was a colorless oil. Contains 8% by weight of isocyano (NCO), viscosity at 25°C is 3200cP, gel time is 5 hours at 25°C, 18°C dew point, 64% humidity. The adhesive had a cured sheet tensile strength of 2160 psi and an elongation at break of 590%.

[0031] Prepare a mixture consisting of 200 grams of polyurethane adhesive and 800 grams of recycled rubber powder with a particle size of 1-3mm, stir the mixture so that the recycled rubber powder is completely wetted by the adhesive, and then pour half of it into 48×30×2cm In the pan, use a roller to press it into a uniform sheet of 9.5-10.5cm, and cure it in the sun at 30-36°C for 4 hours; pour the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com