Axial-shifting noise preventing structure of drum washing machine

A drum washing machine, axial movement technology, applied to other washing machines, washing devices, textiles and paper making, etc., can solve problems such as friction noise and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below with reference to accompanying drawing and embodiment:

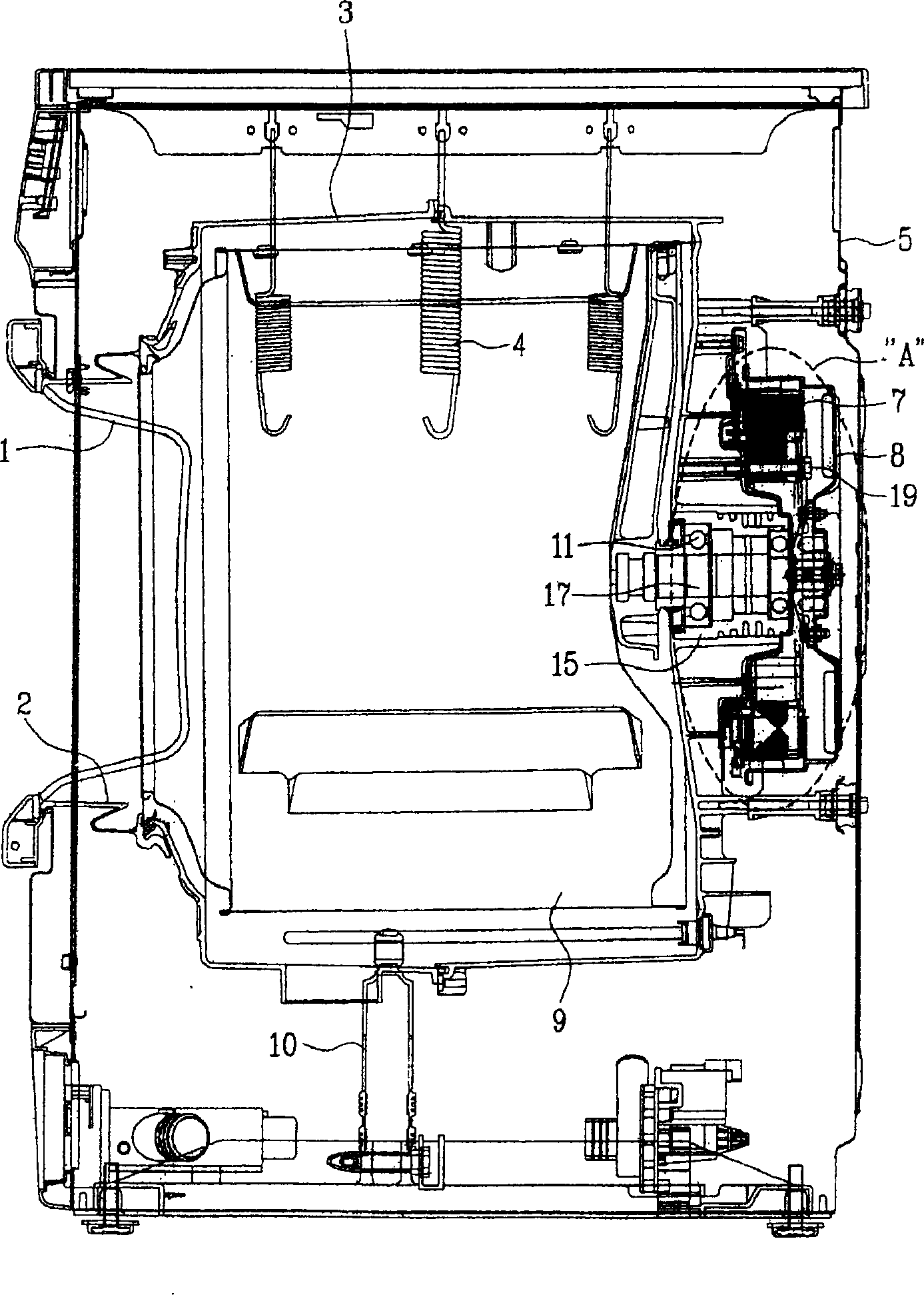

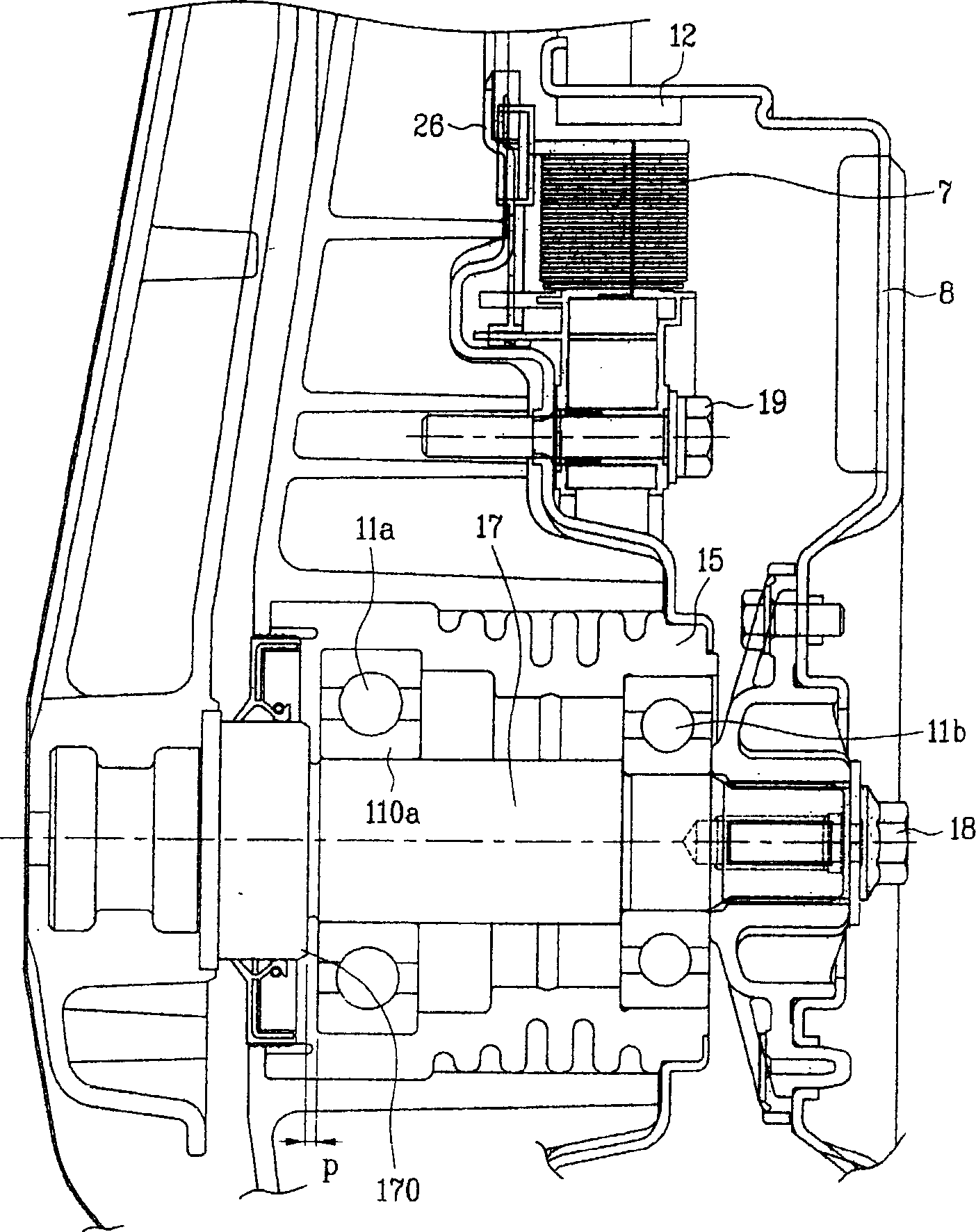

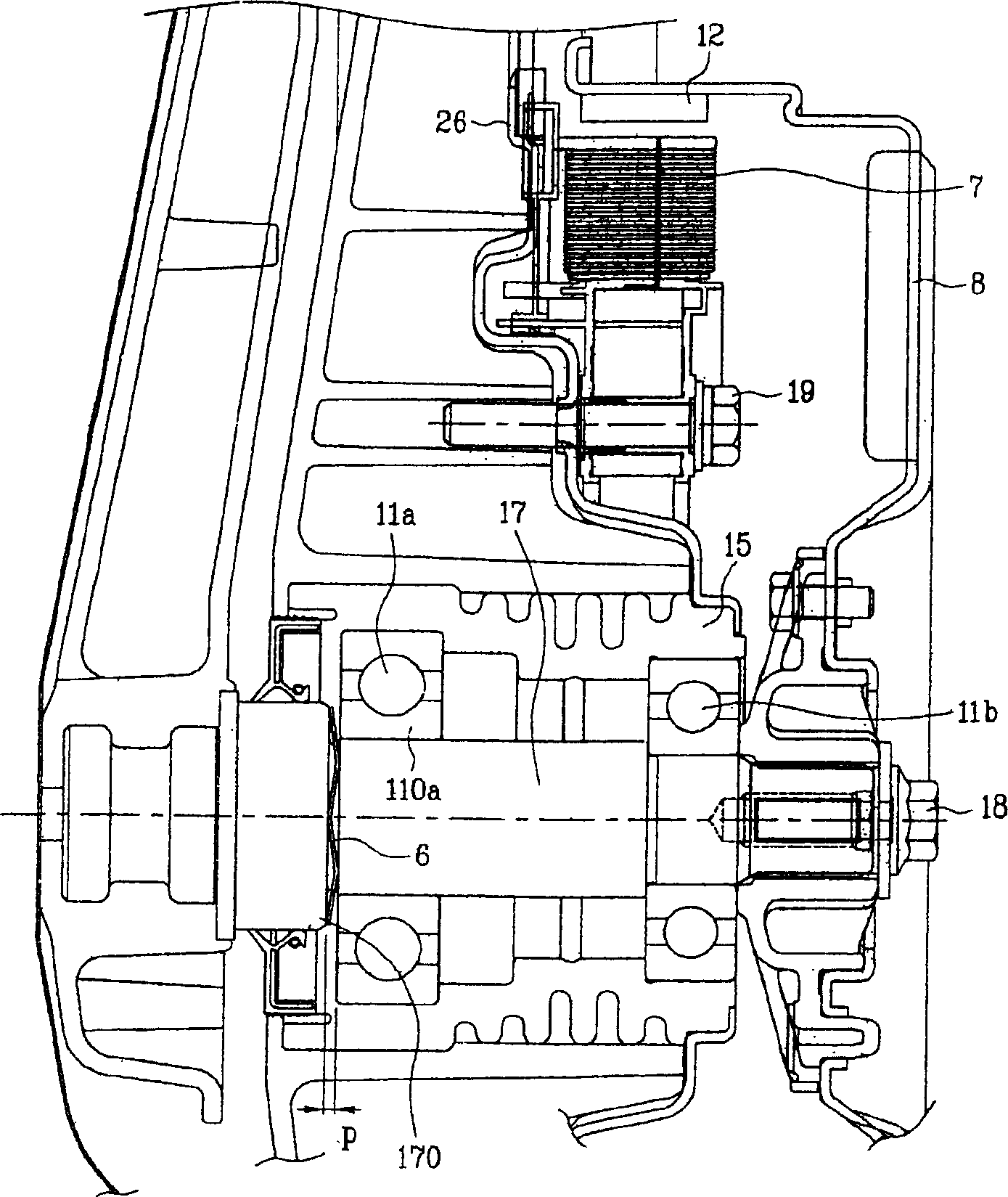

[0028] Such as image 3 , 4 As shown, the technical solution of the present invention is: the stator 7 is fixed on the back of the outer cylinder 3, the rotor 8 is directly connected to the coupling shaft of the drum 9 arranged on the inner side of the outer cylinder 3, and when the stator 7 is powered on, the rotor 8 The rotation of the drum 9 drives the rotation of the drum 9, thereby realizing the functions of washing and dehydration, and in the directly connected drum washing machine with a gap between the ball bearing inner ring supporting the shaft 17 directly connected to the drum 9 and the shaft 17, the shaft 17 Between the inner ring 110a of the ball bearing 11a at the front and the front protrusion 170 of the shaft 17, a shaft with elastic force is provided along the direction of the rotation axis of the drum 9, which can reduce the vibration of the dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com