Pressure sensitive adhesive sheet and process for producing the same

A manufacturing method, a technology of an adhesive sheet, applied to an adhesive method using a foaming adhesive, a film/sheet-shaped adhesive, an adhesive, etc., can solve air residue, a lot of time and effort, and cannot be applied to a machine Attachment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

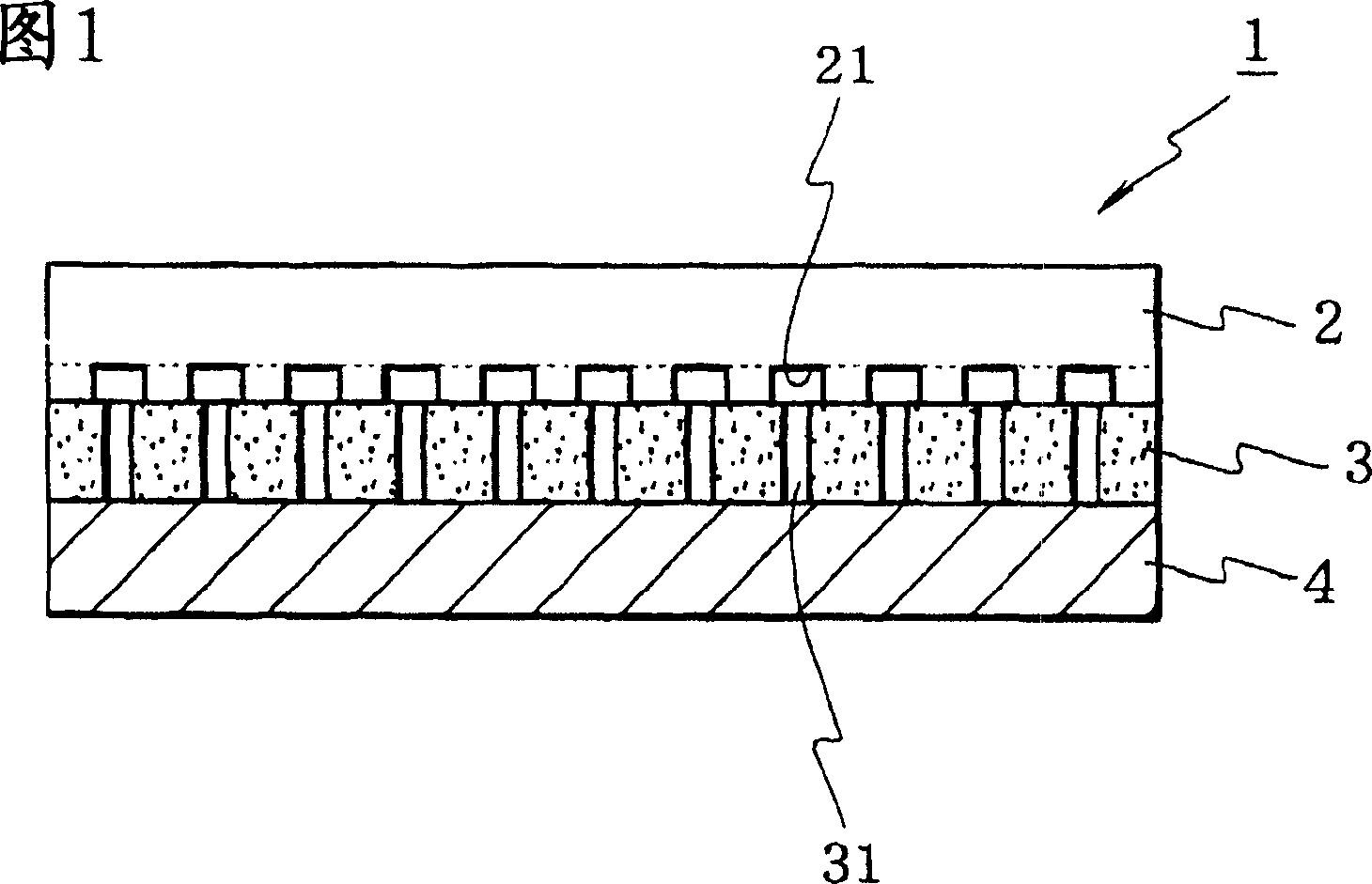

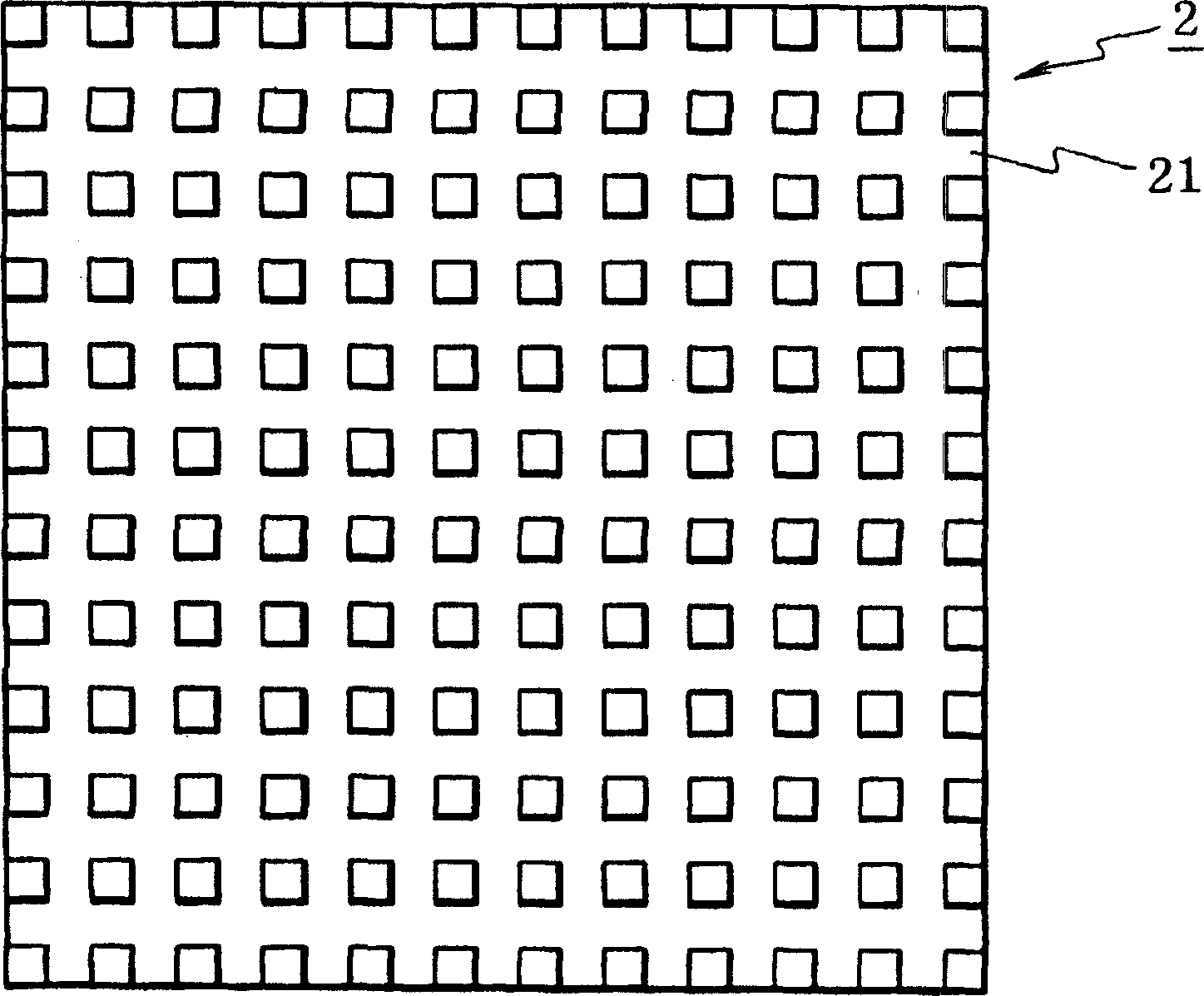

[0056] Fig. 1 is a cross-sectional view of an adhesive sheet 1 according to a first embodiment of the present invention.

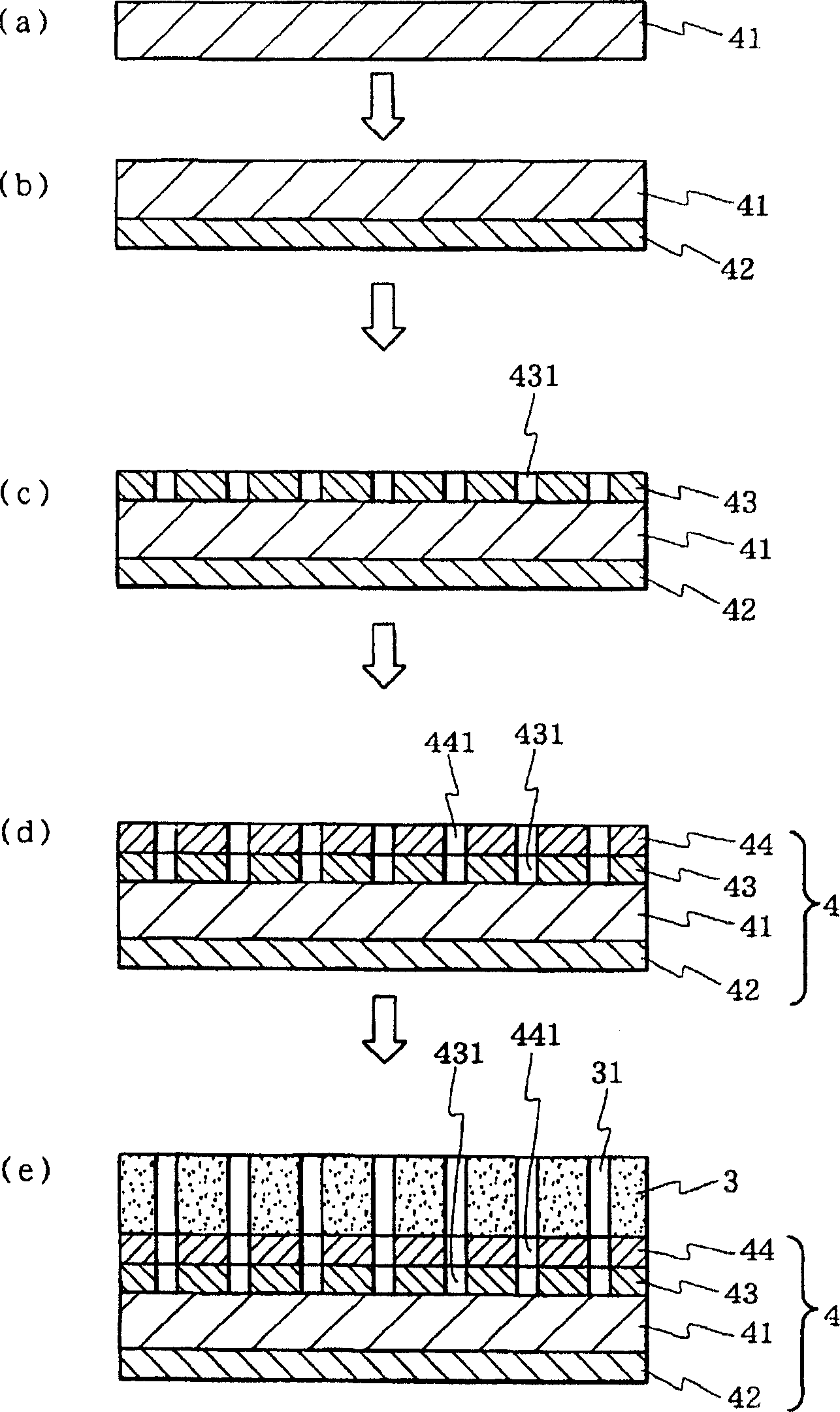

[0057] As shown in FIG. 1 , the PSA sheet 1 according to this embodiment is a PSA sheet constituted by laminating a substrate 2 , an PSA layer 3 , and a release material 4 . Here, the release material 4 is a release material that is peeled off when the pressure-sensitive adhesive sheet 1 is used.

[0058] The adhesive layer 3 side of the base material 2 in this embodiment is provided with a groove 21 that continues to the side end portion of the base material 2 . As will be described later, the end of the groove 21 is preferably selected so that the gas from the through passage 31 of the adhesive layer 3 passes through the groove 21 to the outside of the adhesive sheet 1, and also in order not to limit the direction of gas removal. It exists on several sides of the base material 2, and further exists on all sides (full circumference). In this embodiment,...

no. 2 Embodiment approach

[0118] exist Figure 5 The first example of the pressure-sensitive adhesive sheet according to the second embodiment of the present invention is shown in , and the second example is shown in FIG. 6 .

[0119] PSA sheets 1A and 1A' according to the second embodiment have the same configuration as the PSA sheet 1 according to the first embodiment except that the PSA layers 3A and 3A' have air bubbles passing through them.

[0120] exist Figure 5 The penetrating path in the adhesive layer 3A of the adhesive sheet 1A shown is formed by the continuous air cells penetrating the adhesive layer 3A in the thickness direction, or the air cell film or the wall between the air cells is destroyed by an external force, and can be broken in the thickness direction. The independent air cells penetrating through the adhesive layer 3A constitute. The penetrating paths in the adhesive layer 3A do not necessarily have to independently penetrate the adhesive layer 3A.

[0121] On the other han...

no. 3 Embodiment approach

[0135] Figure 7 It is a cross-sectional view of an adhesive sheet 1B according to a third embodiment of the present invention.

[0136] like Figure 7 As shown, the PSA sheet 1B according to this embodiment is a PSA sheet in which a base material 2B and an PSA layer 3B are laminated.

[0137] The base material 2B in this embodiment is comprised from the surface base material 22B, and the foam layer 23B which consists of foams. Examples of the material of the surface substrate 22B include, but are not particularly limited to, resin films, metal films, metal-deposited resin films, paper, nonwoven fabrics, and laminates thereof. The thickness of the surface substrate 22B is usually about 1 to 500 μm, preferably about 3 to 300 μm.

[0138] On the other hand, as the foam constituting the foam layer 23B, for example, poly(meth)acrylate, polystyrene, polyurethane, polyethylene, polypropylene, polyvinyl chloride, cellulose acetate, rubber, organic A foam made of resin such as sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com