Electric cycle frame with motor

A technology for mid-mounted motors and electric vehicles, applied to motor vehicles, bicycle racks, motorcycles, etc., can solve the problems of inconvenient installation, difficult positioning, and large deformation of mid-mounted motors, and achieve high concentricity, low cost, and low deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

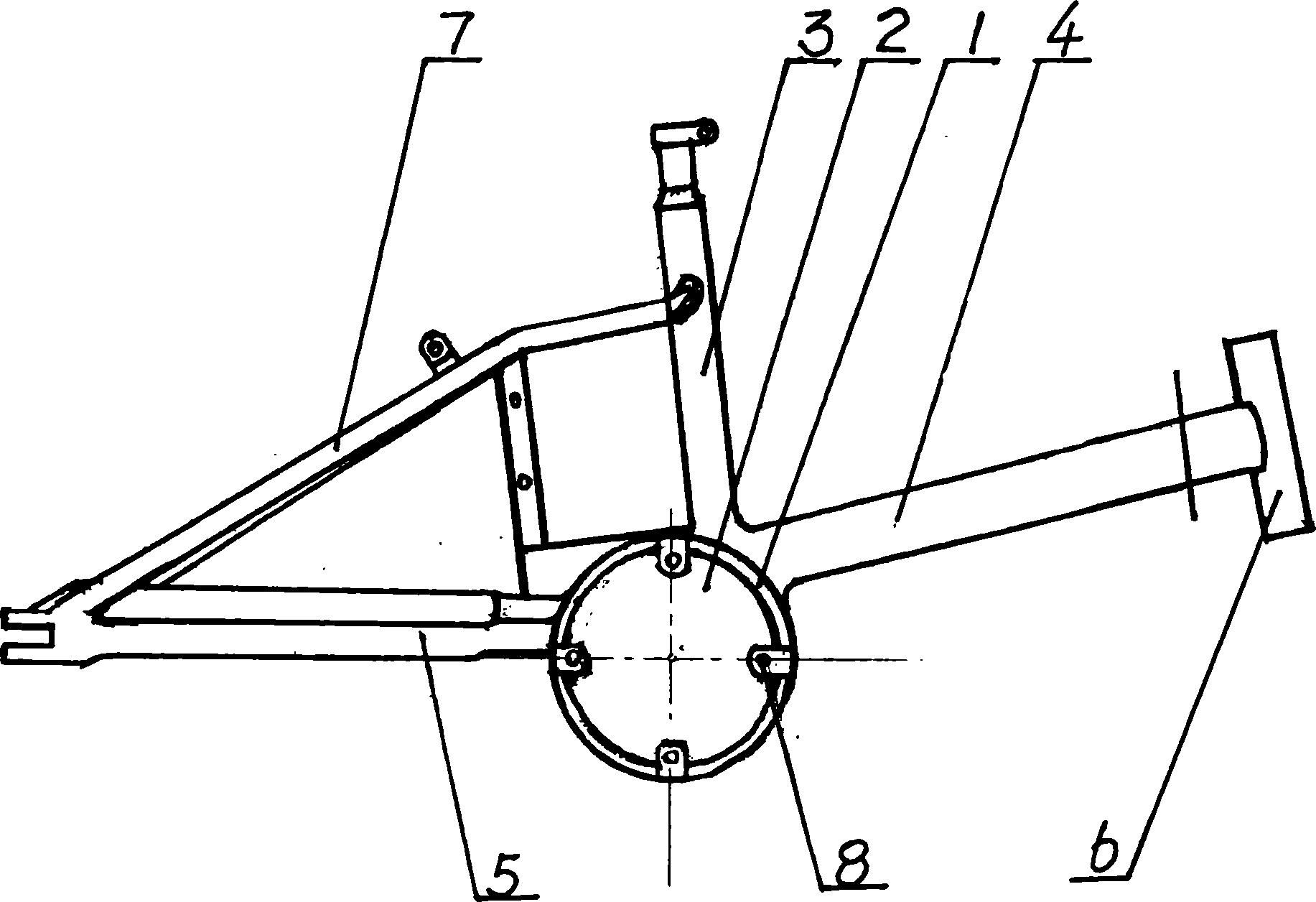

[0010] In order to further understand the features and effects of the present invention, the following embodiments are given as examples and described in detail with the accompanying drawings as follows. Please refer to figure 1 .

[0011] like figure 1 Shown: the bottom bracket tube 1 is a closed cylindrical tube, and its inner diameter should match the outer diameter of the central motor 2. The frame riser tube 3, the frame lower tube 4 and the rear flat fork 5 are respectively welded in their original positions. Fix the five-way pipe 1 of the central motor. The motor 2 is placed in the five-way pipe 1, and the two ends of the five-way pipe 1 are fixed with bolts 8. The other end of the frame down tube 4 is welded with a front tube 6, a vertical fork 7 is welded between the frame stand tube 3 and the rear flat fork 5, and the five-way tube 1 can also be made into two semi-cylindrical tubes, and the two The ends have connecting lugs and are bolted, and can also be made int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com