Electrojet engine variable working displacement control technique

A control technology, displacement controller technology, which is applied in the control field of electronically controlled fuel injection internal combustion engines, can solve problems such as unrealizable and non-operable, and achieve the effects of reducing cylinder wear, stable operation, and reducing emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

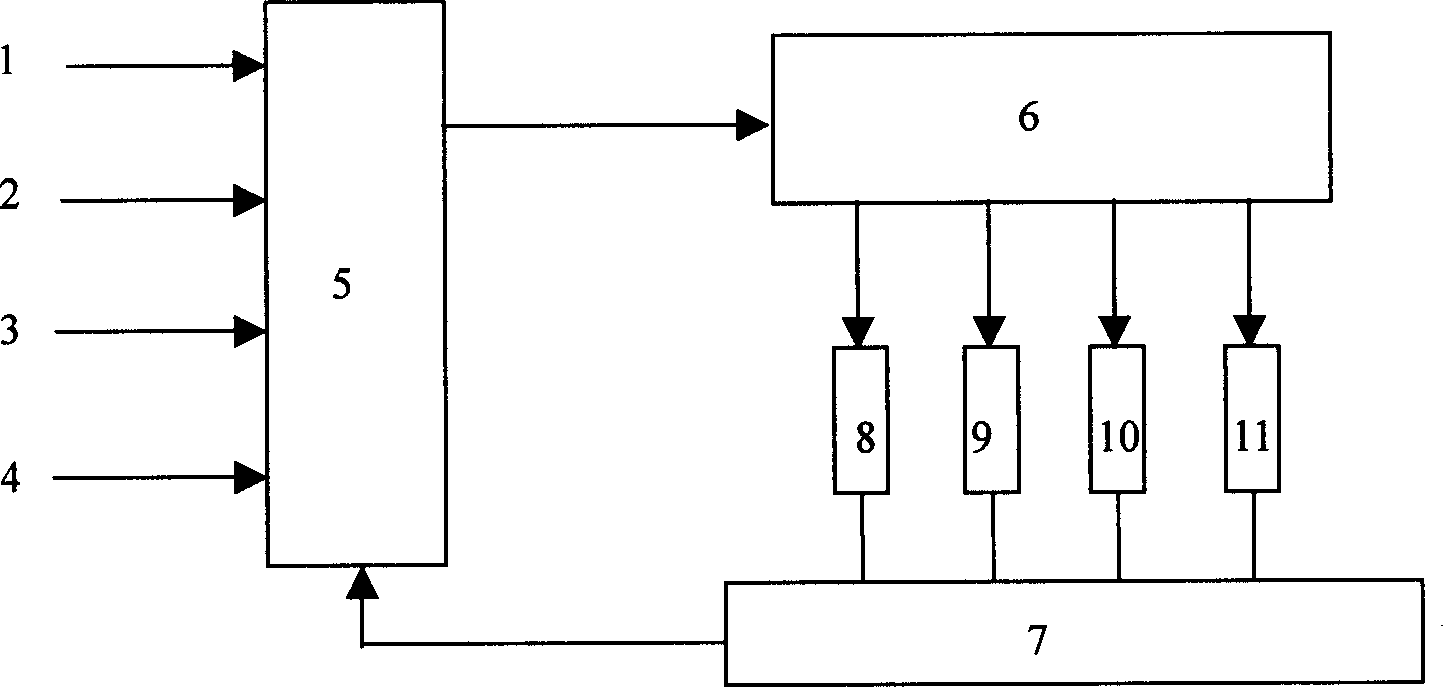

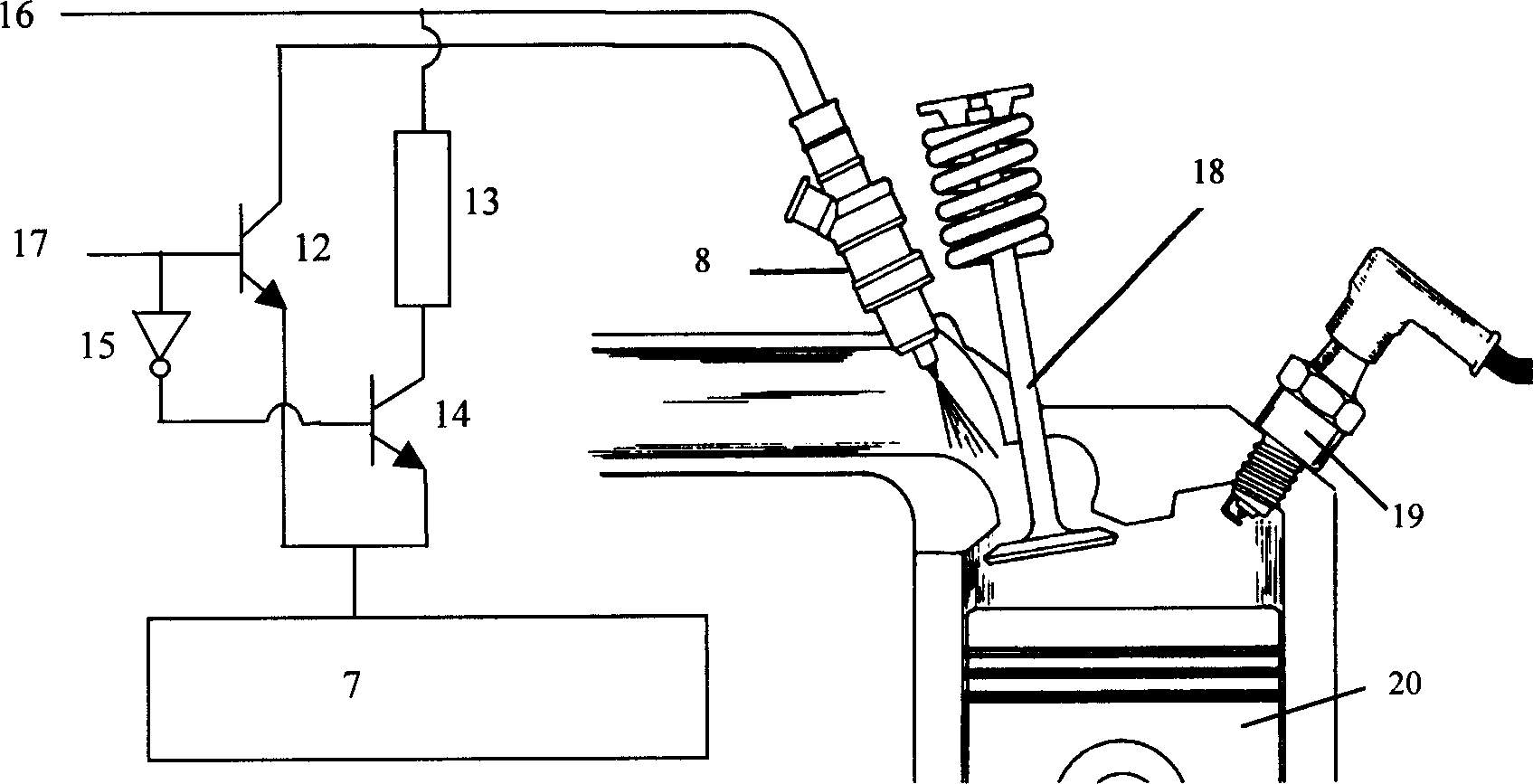

Method used

Image

Examples

Embodiment 1

[0043] Simple control of 4-cylinder engine, 2 input parameters, 3 working displacements

[0044] This embodiment has only 50%, 75%, 100% three kinds of working displacements, and what table 1 shows is the variable working displacement variation rule (fuel injection rule) of embodiment 1. Its fuel injection (working) sequence is 1-3-4-2. This fuel injection rule takes 4 working cycles as a control period. The 4 cylinders are divided into two groups, the 1st and 4th cylinders are a group, and the 2nd and 3rd cylinders are a group. The numbers 1, 2, 3, and 4 in the table are the cylinder numbers, and the numbers with "○" are the cylinders with fuel injection stopped. The working displacement percentage is the ratio of the actual working displacement to the design displacement. It is equal to the ratio of the number of actual fuel injection (work) to the total number of total work (fuel injection) (16 times) in this cycle (4 cycles). For example, in the second line of the tabl...

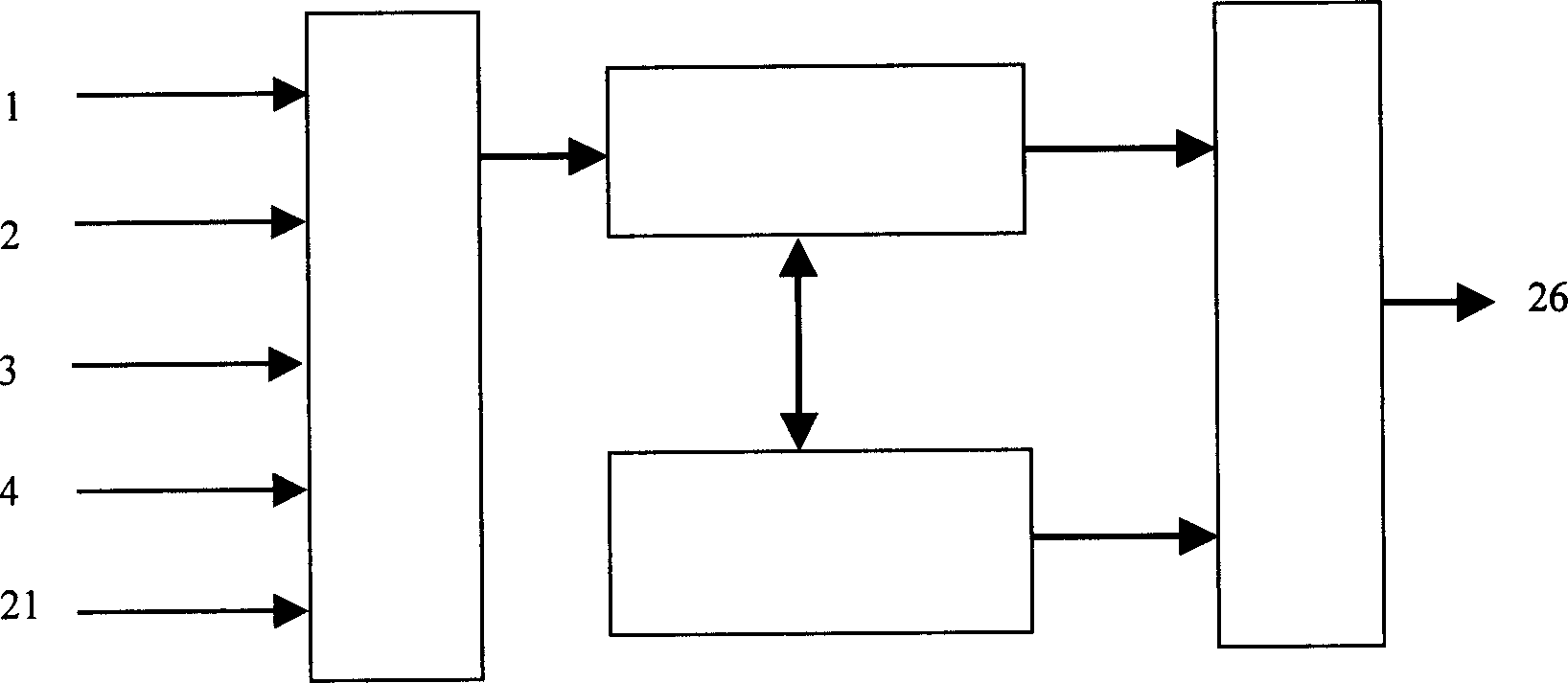

Embodiment 2

[0052] Control of 4-cylinder engine, 4 input parameters, and 5 working displacements.

[0053] This embodiment has five working displacements of 50%, 62.5%, 75%, 87.5%, and 100%. Table 3 is the variable working displacement fuel injection law (pattern) table of embodiment 2. Similar to Table 1, the working displacement increases by 87.5% between 100% and 75% working displacement, and increases by 62.5% between 75% and 50% working displacement.

[0054] Its general rules are:

[0055] 1. Divide all 4 cylinders of the engine into two groups equally, each group has 2 cylinders.

[0056] 2. The 1st and 4th cylinders of the inline 4-cylinder engine are one group, and the 2nd and 3rd cylinders are another group;

[0057] 3. Set 4 working cycles as a control cycle;

[0058] 4. Design cylinder oil injection or pause cycle alternately. In one control cycle, the suspended cylinders should be as uniform as possible, and the same cylinder should not be suspended for more than one cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com