Rotor axial regulator

An adjustment device, axial technology, applied to the components of the pumping device for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problem of not being able to adjust in both directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

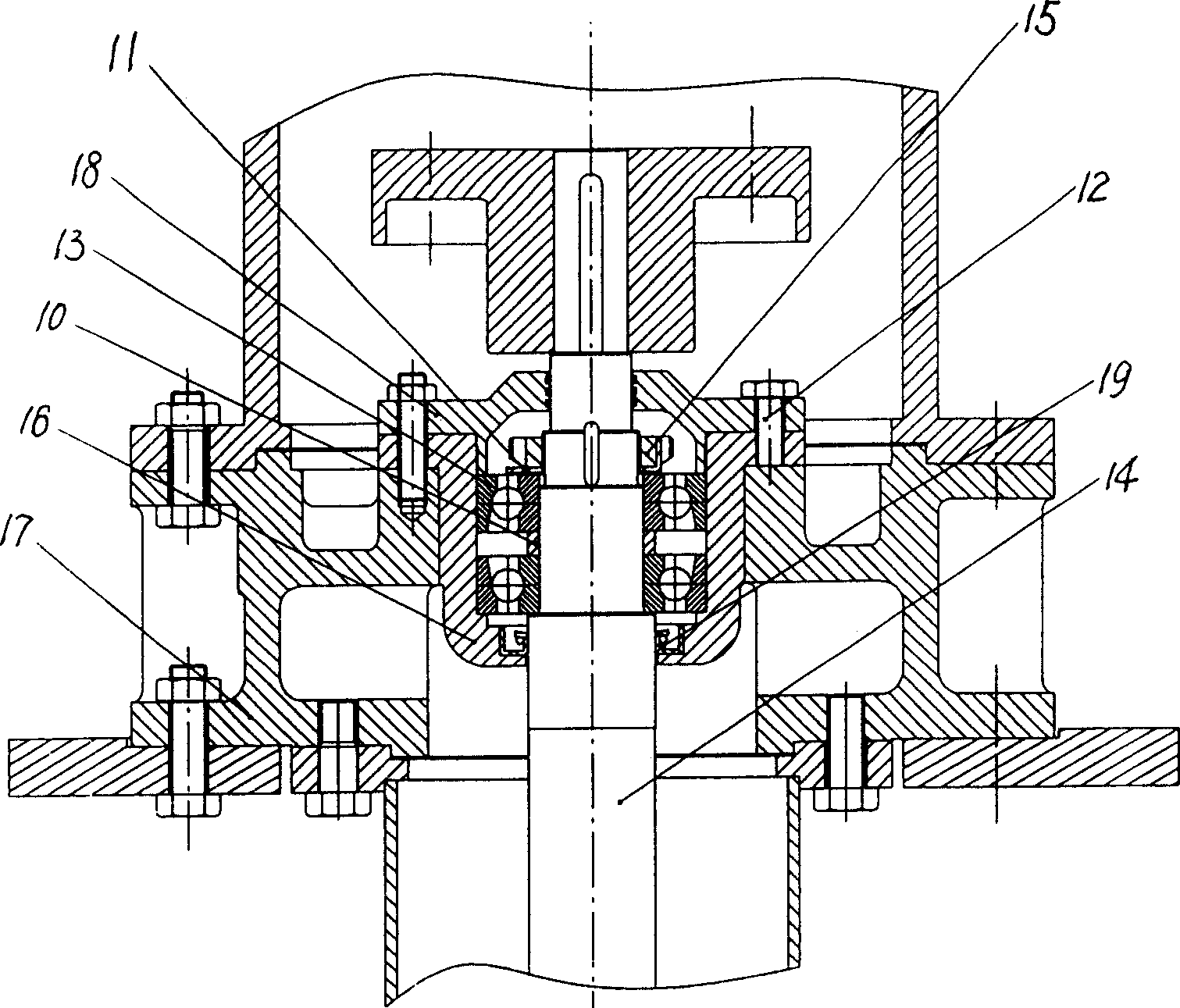

[0020] see figure 2 , the present invention is an axial adjustment device of a long-axis submerged chemical pump, which is equipped with a bearing bracket 27 and a bearing body 26, and the shaft 24 runs through the bearing body 26. Angular contact ball bearings 23 used in pairs are arranged in the bearing body 26 , and the retaining sleeve 20 is installed between the angular contact ball bearings 23 . Bearing cover 28 is installed on bearing body 26, and is fastened by cover screw 22.

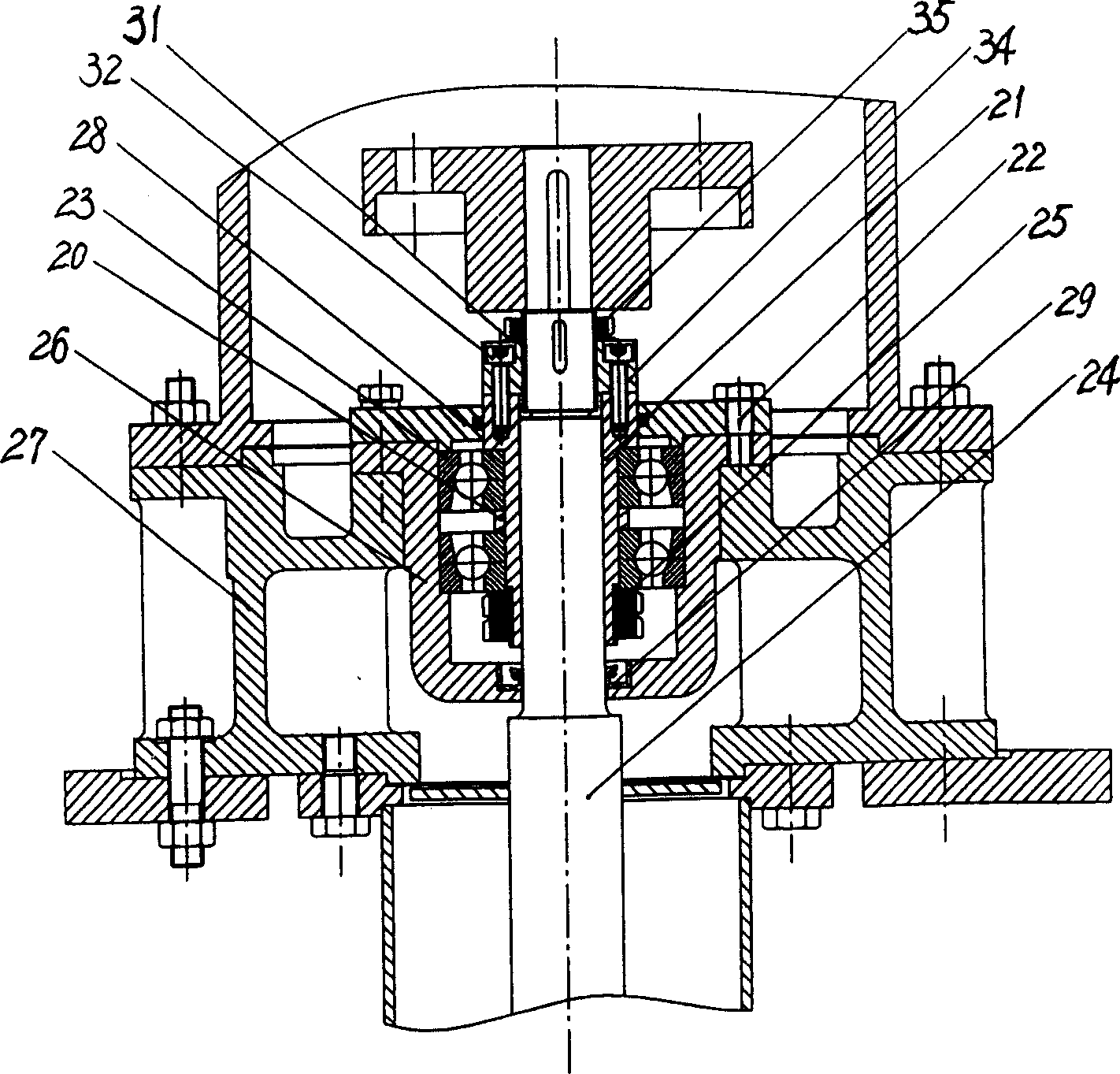

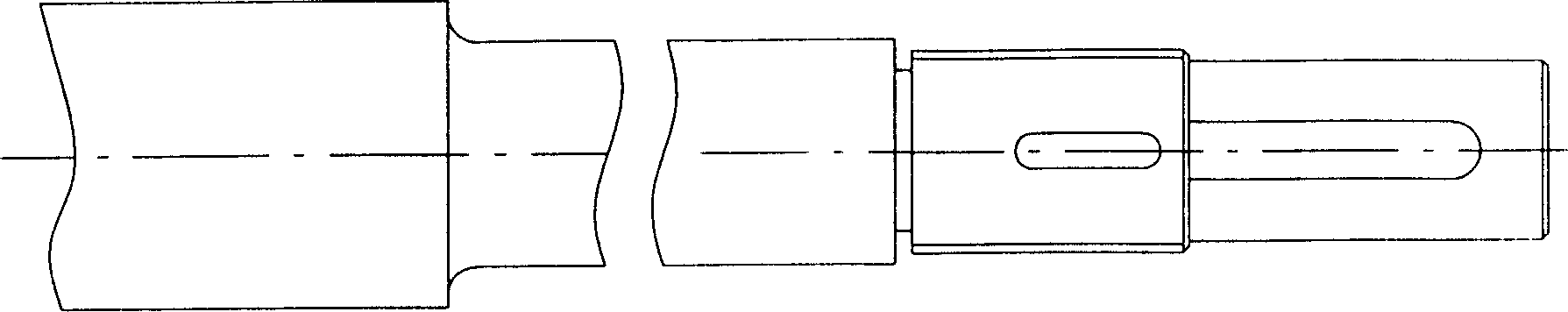

[0021] combined reference Figure 3 to Figure 9 , A shaft sleeve 21 is installed on the shaft section in the bearing body 26, the shaft 24 and the shaft sleeve 21 are clearance fit, and the angular contact ball bearing 23 is installed on the shaft sleeve 21. The large-diameter end of the shaft sleeve 21 is provided with a bearing positioning step 211 , and the angular contact ball bearing 23 is positioned and installed in the bearing positioning step 211 . The small-diameter end of the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com