Plate glass direction conversion device

A flat glass, direction conversion technology, applied in glass cutting device, glass forming, glass re-molding and other directions, can solve the problems of complex structure, increased contact area, difficult to apply to production lines, etc., to achieve simplification of structure, power and The effect of structure miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

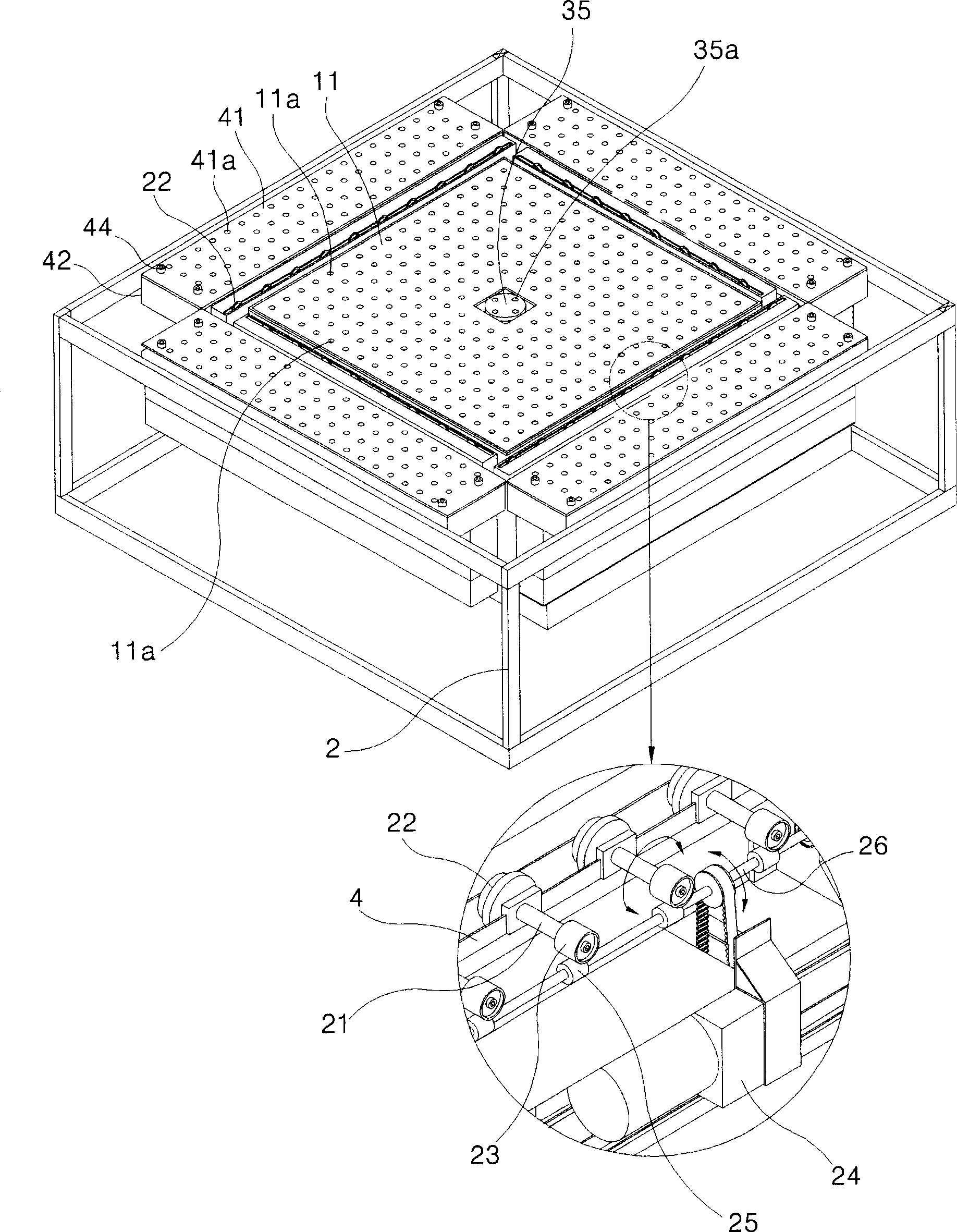

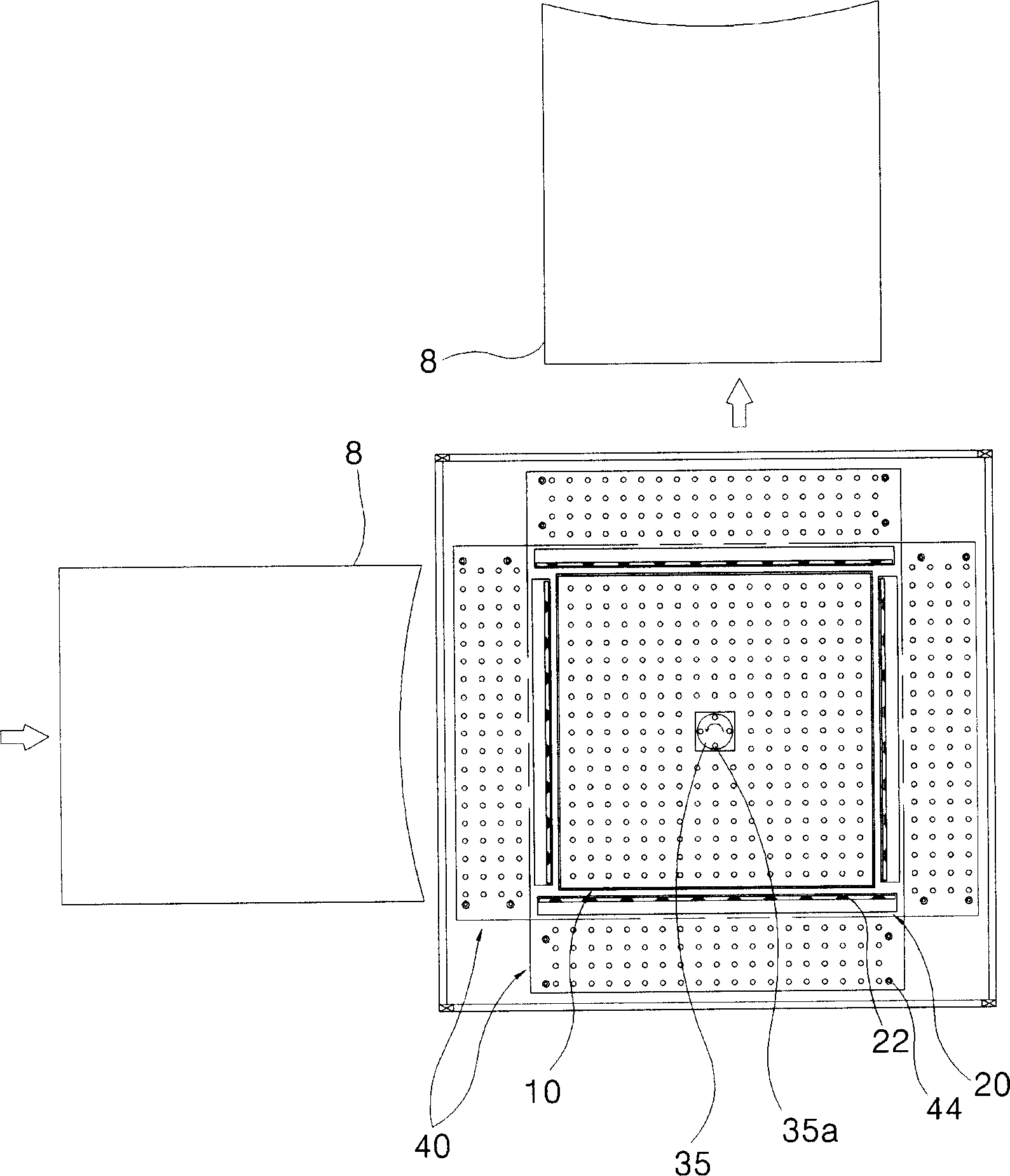

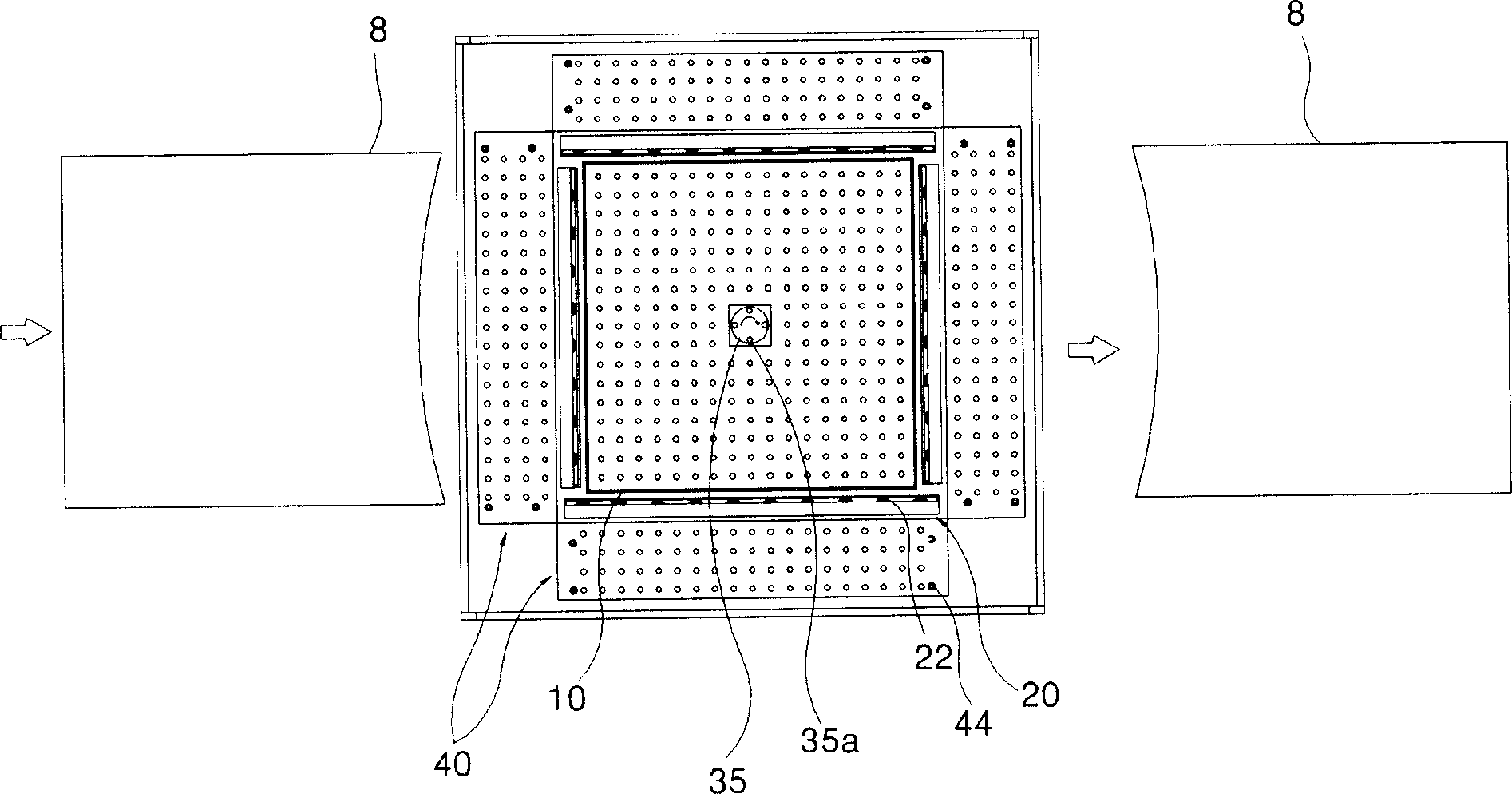

[0059] Hereinafter, a preferred embodiment of the present invention will be described in detail based on the drawings.

[0060] Such as Figure 1 to Figure 6 As shown, the structure of the direction changing device for plate glass of the present invention includes: an air ejector 10 for air-floating the plate glass 8 on the upper surface of the main frame 2; and a roller transfer machine 20 provided on the air ejector 10 adjacent to the outer circumferential surface; the rotating machine 30 is arranged in the center of the air ejector 10, so that the plate glass 8 loaded on the roller conveyor 30 rotates in situ.

[0061] The above-mentioned main frame 2 is a frame type used to support the roller support table 4 on its upper part; wheels (not shown) for transferring the main frame 2 to a specific place are provided at the lower end of each corner; and while being fixed to the desired position , A leveler (not shown) for maintaining the level of the main frame 2 is provided.

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com