Floating-hammer randow directional floating-gyro inclinometer

A technology of inclinometer and pendulum weight is applied in the field of floating weight random orientation floating gyro inclinometer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

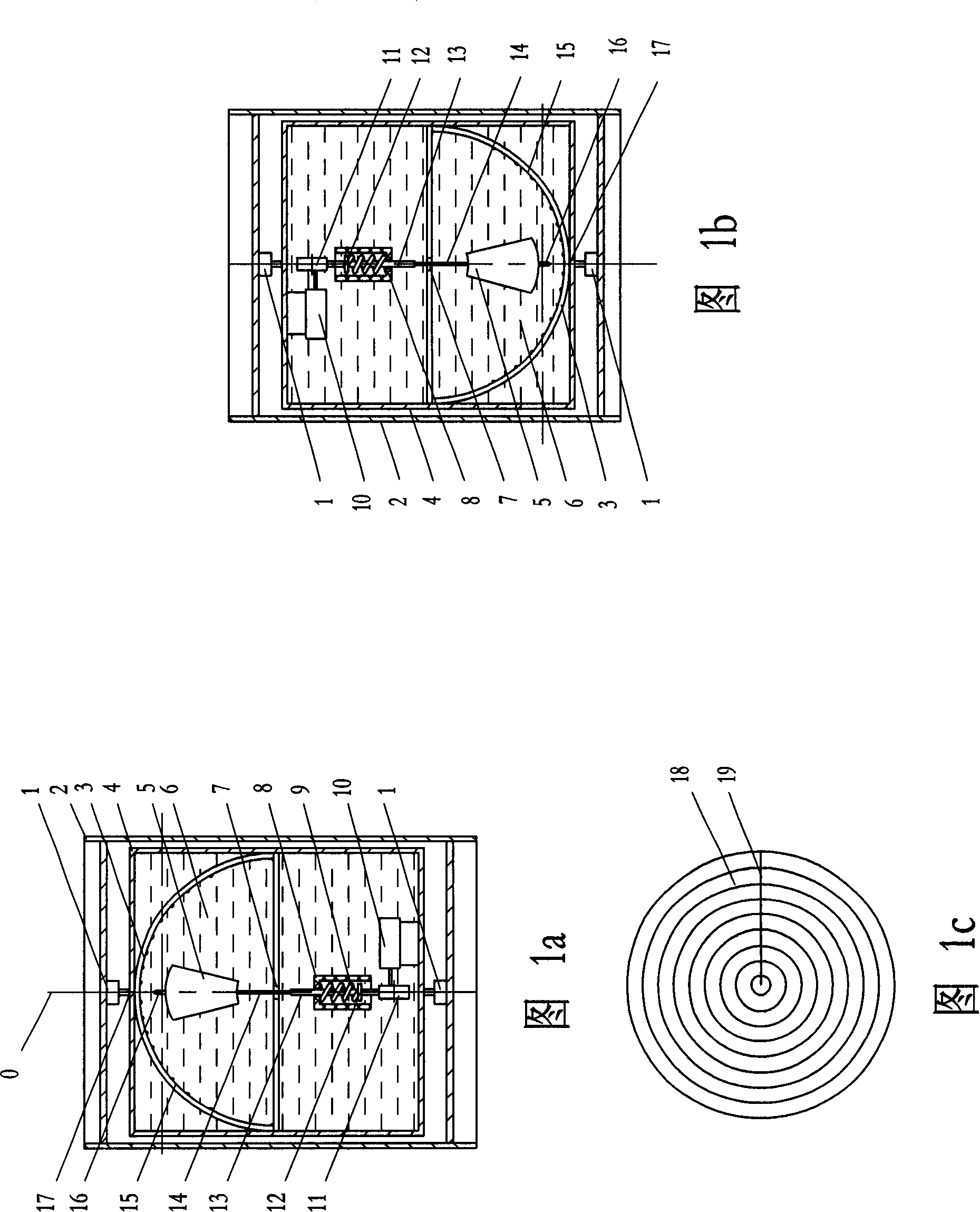

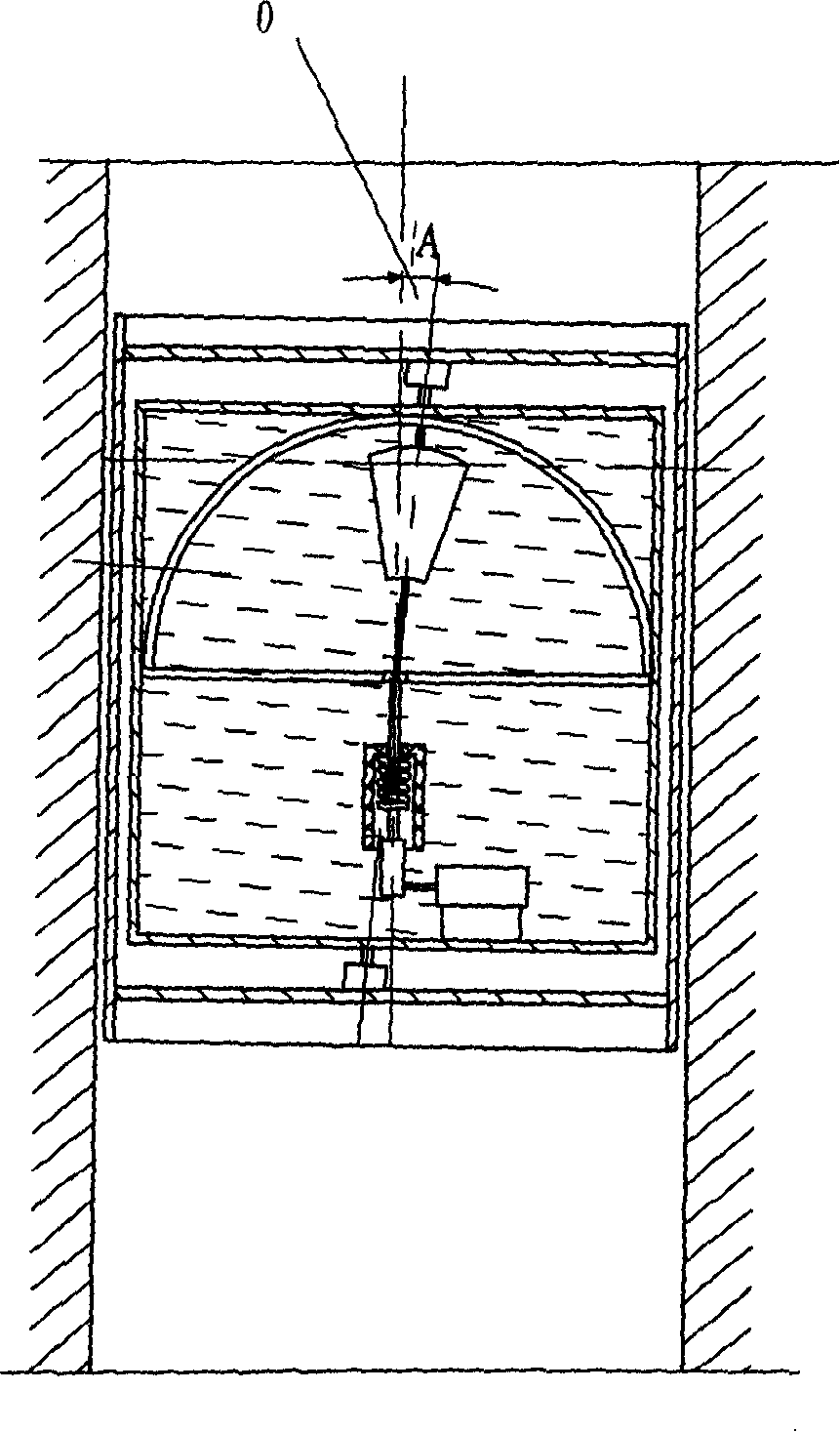

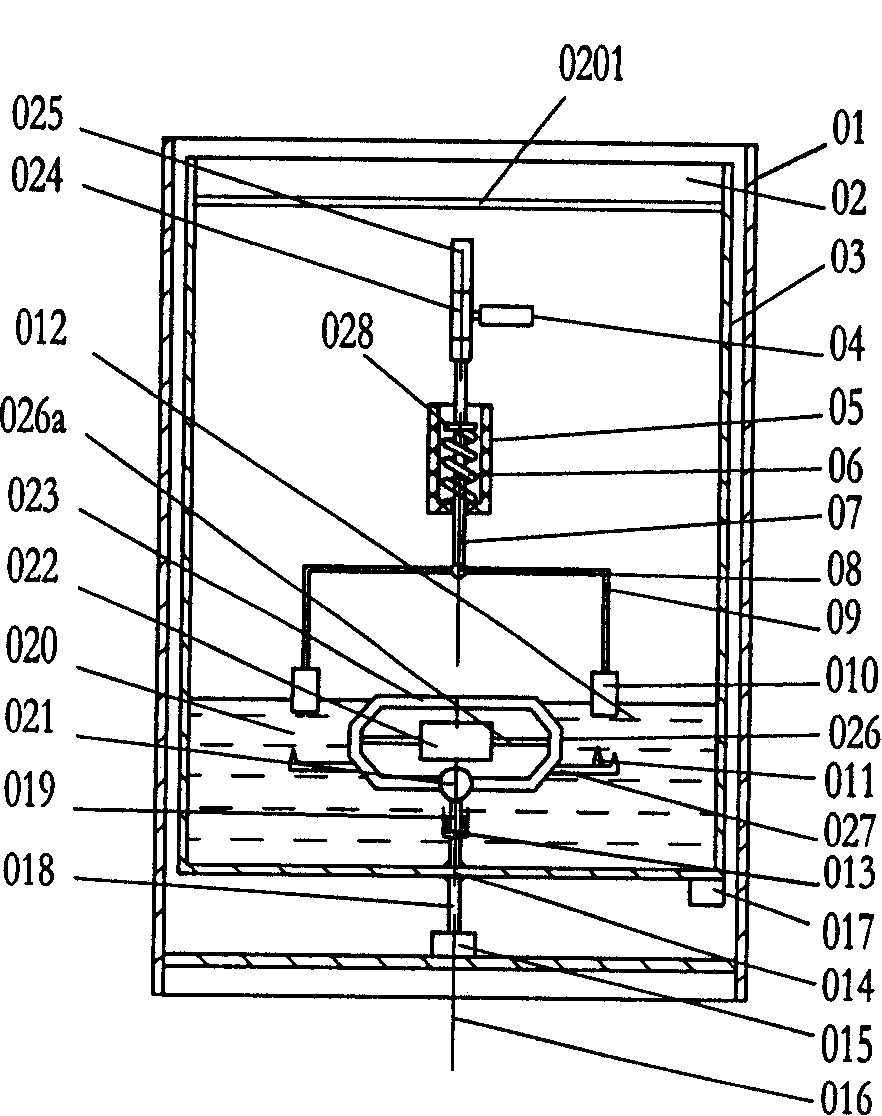

[0025] Such as Figure 1a , 1b , 1c, the inclinometer includes a probe casing 2, in which a sealed cylinder-shaped sealing chamber 4 is coaxially arranged in the middle, and a central shaft is arranged on the central axis of the upper and lower ends of the sealing chamber 4, and a central shaft is arranged at the center of the sealing chamber 4. A bearing 1 is arranged on the shaft, which is supported and fixed on the probe shell 2 through the bearing 1; the sealing chamber 4 is filled with insulating fluid 6, and a vertex potentiometer 3 is arranged in the sealing chamber 4, and the vertex potentiometer 3 is a hemispherical shell body, the diameter of the hemispherical shell is equal to the inner diameter of the sealed chamber, and it is fixed on the inner wall of the sealed chamber, and a cover plate is fixedly connected on its bottom circular surface, and the hemispherical shell located at the top angle potentiometer 3 on the cover plate A central hole 7 is provided at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap