Magnetic frequency-variation flaw detection apparatus for black metal wire material

A flaw detection device, ferrous metal technology, applied in the direction of material magnetic variables, etc., can solve the problem that the wire detection can not move forward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

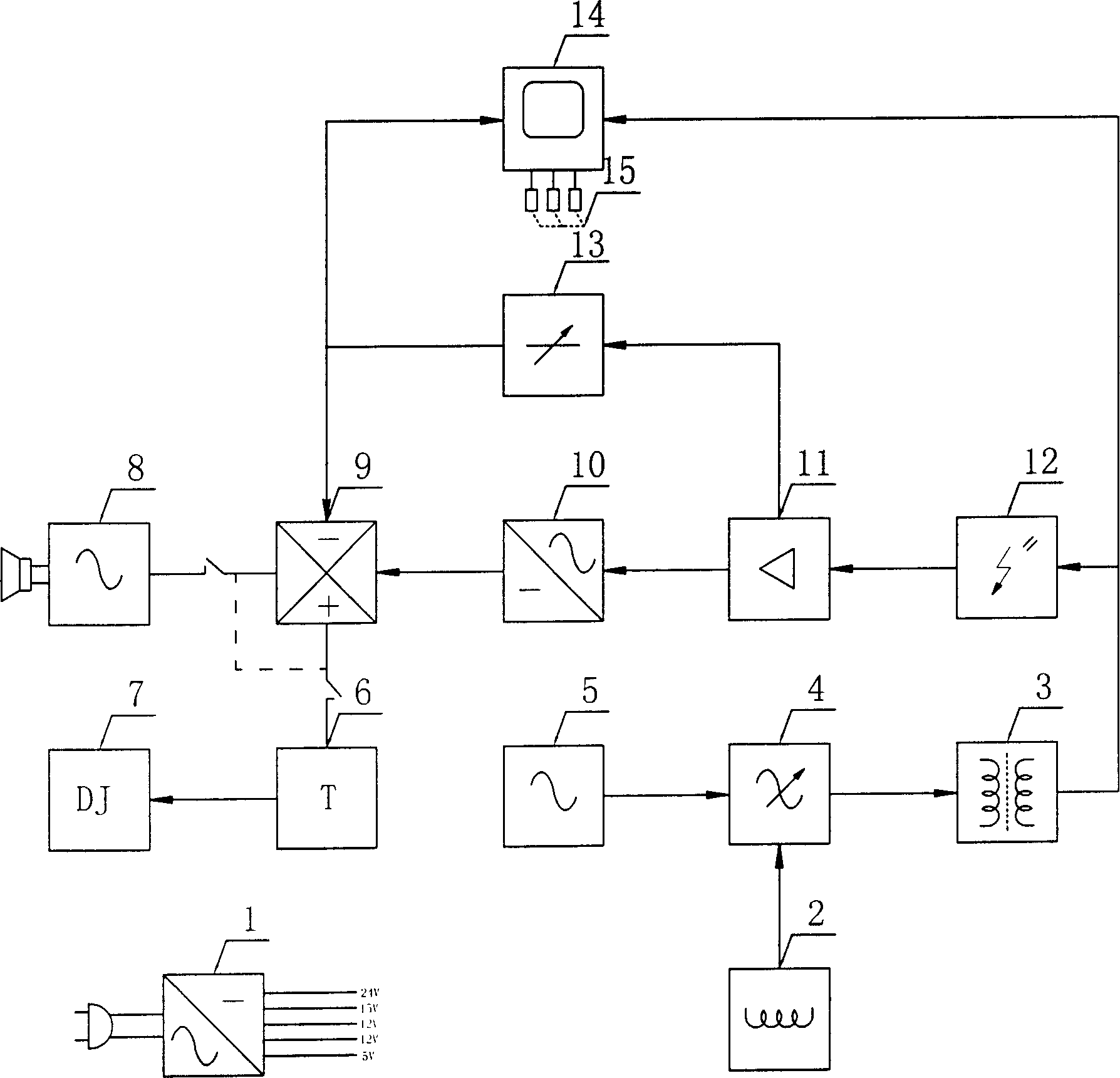

Method used

Image

Examples

Embodiment Construction

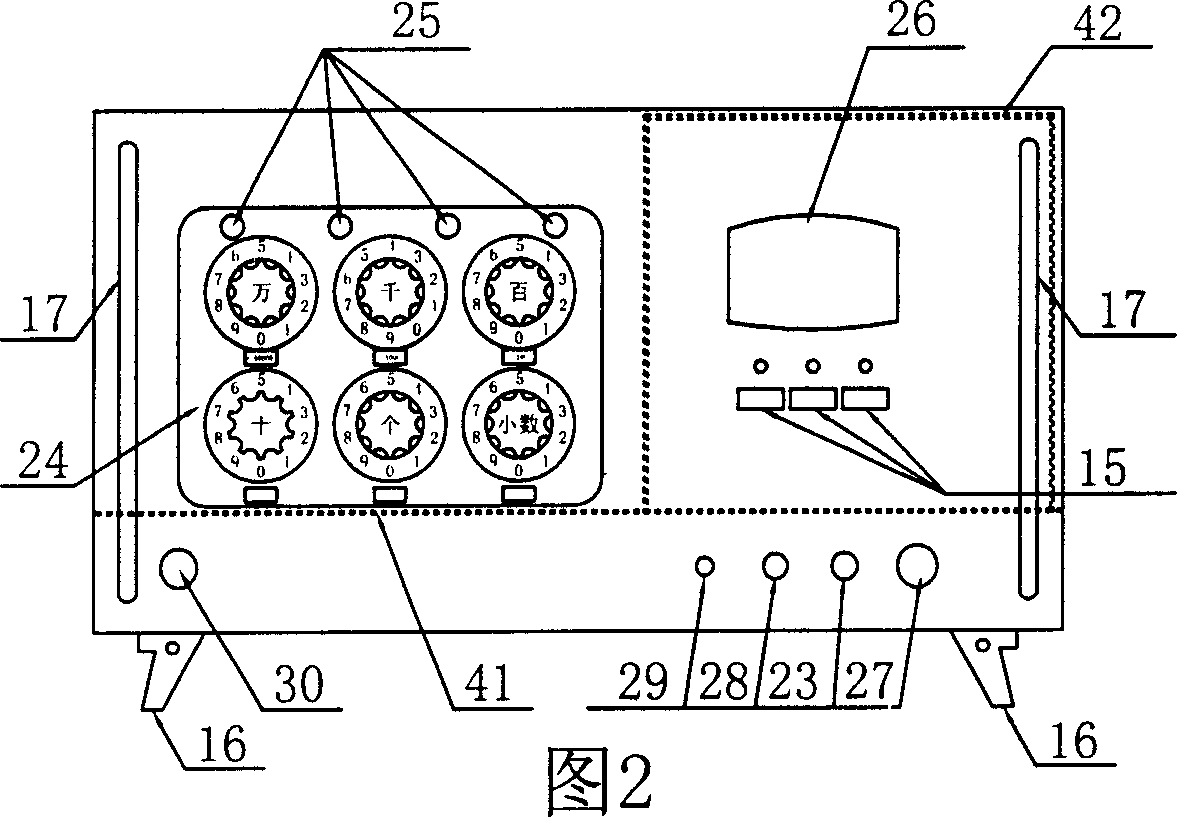

[0013] Put the material to be tested into the magnetic induction coil 2 of the probe, and locate any segment without moving it. A small segment of it touches the frequency conversion adjustment circuit and participates in frequency conversion adjustment. This segment of material is also called "calibration segment." Frequency regulator 24 There are 10,000, 1,000, 100, 10, 1, and 10 decimals in six disks and ten files; the thousand file is set at 9, and the rest are all set at 0. After the power is turned on, the alarm will beep, and it will return from 9 according to the method of high to low. To 1, from thousands to ones, adjust the frequency regulator knob, the adjustment speed is moderate, subject to the stability of the LCD digital display 14, the tens of thousands does not need to be adjusted, first adjust the thousands of gear knob, the alarm stop gear is the definite gear According to this method, adjust the hundreds, tens, and ones. After the adjustment, move the probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com