Opto-electronic device comprising a laser integrated with a modulator and method of fabrication thereof

一种集成调制器、光电设备的技术,应用在激光器、激光器零部件、半导体激光器等方向,能够解决难以完全控制外延生长、寄生电容不允许高吞吐量使用、复杂制作工艺等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

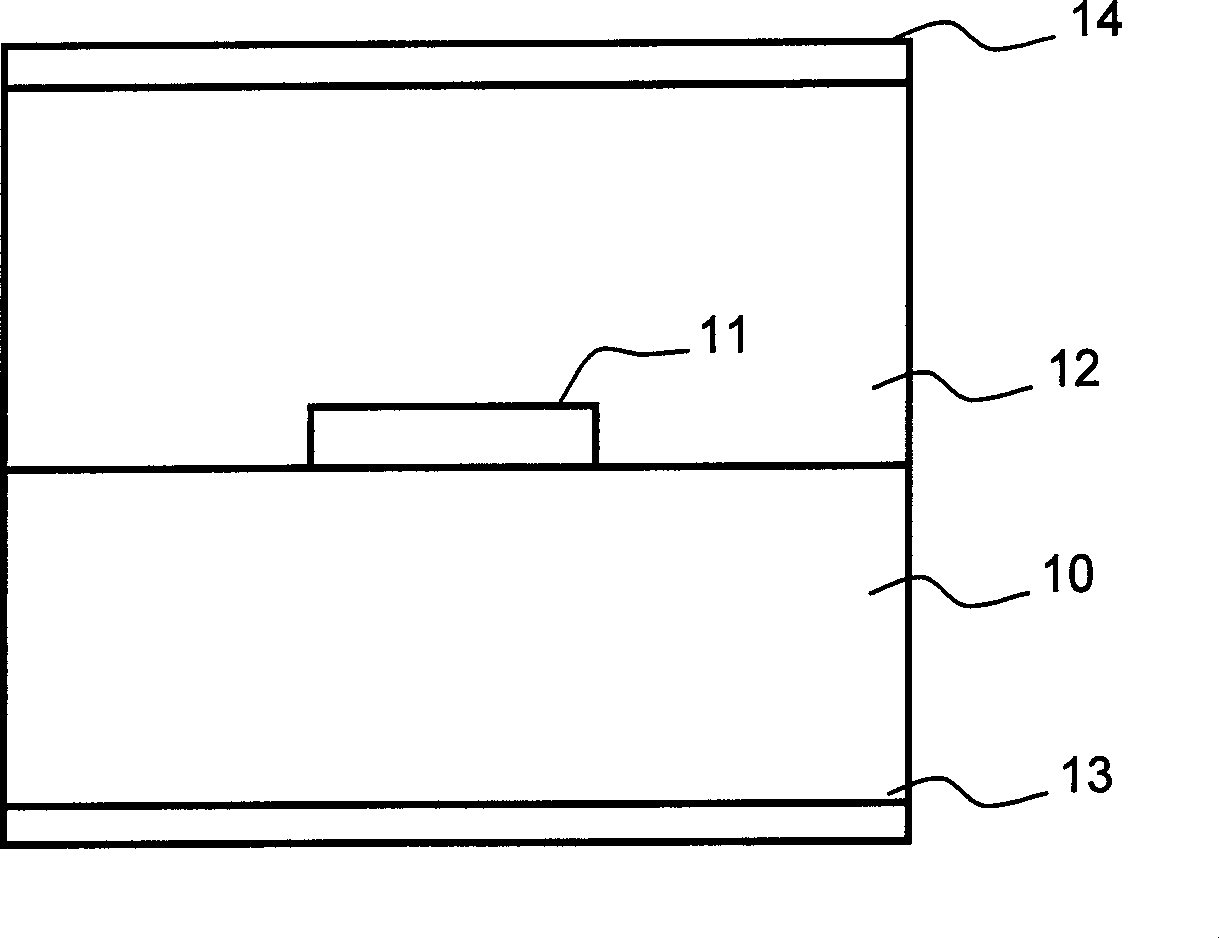

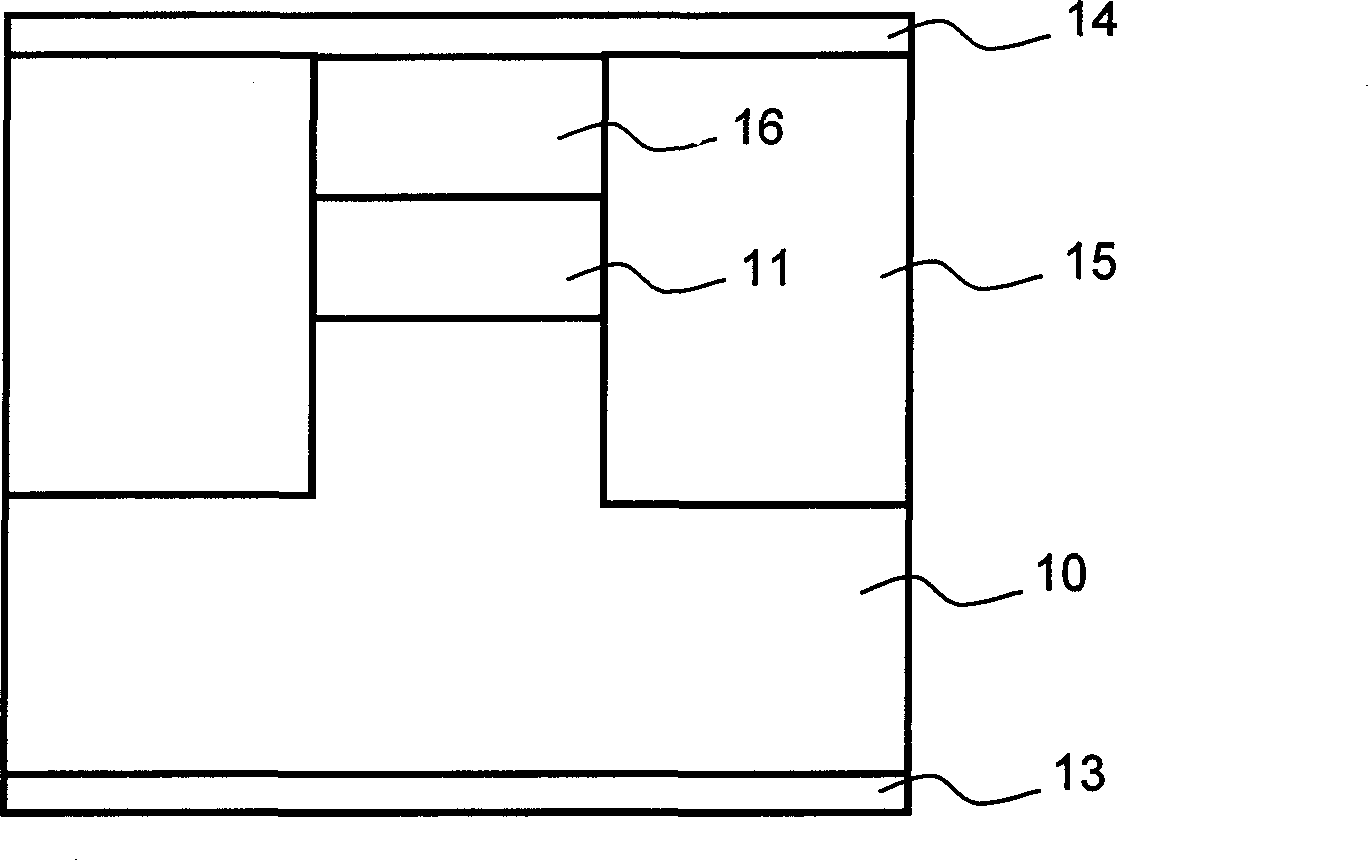

[0050] Figure 4 The sectional view of shows an ILM type device according to the invention, comprising a laser part and a modulating part. It mainly consists of generic structures of the P.I.N type, which in succession include:

[0051] a substrate 10 made of n-doped semiconductor material,

[0052] a buried active region 11 formed by strips of rectangular cross-section,

[0053] • A p-doped vertical confinement layer 16, the sides of the active region surrounded by a semi-insulating lateral confinement layer (not shown in the figure) made of doped semiconductor material.

[0054] The laser part comprises a barrier layer 17 made of n-doped semiconductor material interposed between a semi-insulating lateral confinement layer and a vertical confinement layer.

[0055] The substrate, vertical confinement layer, lateral confinement layer and barrier layer are mainly made of a first semiconductor material whose composition belongs to groups III and V of the periodic table. For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com