Over boosting prevention circuit

A booster circuit and circuit technology, applied in logic circuits, electrical components, conversion equipment without intermediate conversion to AC, etc., can solve problems such as inability to share reference voltages, and achieve the effect of preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

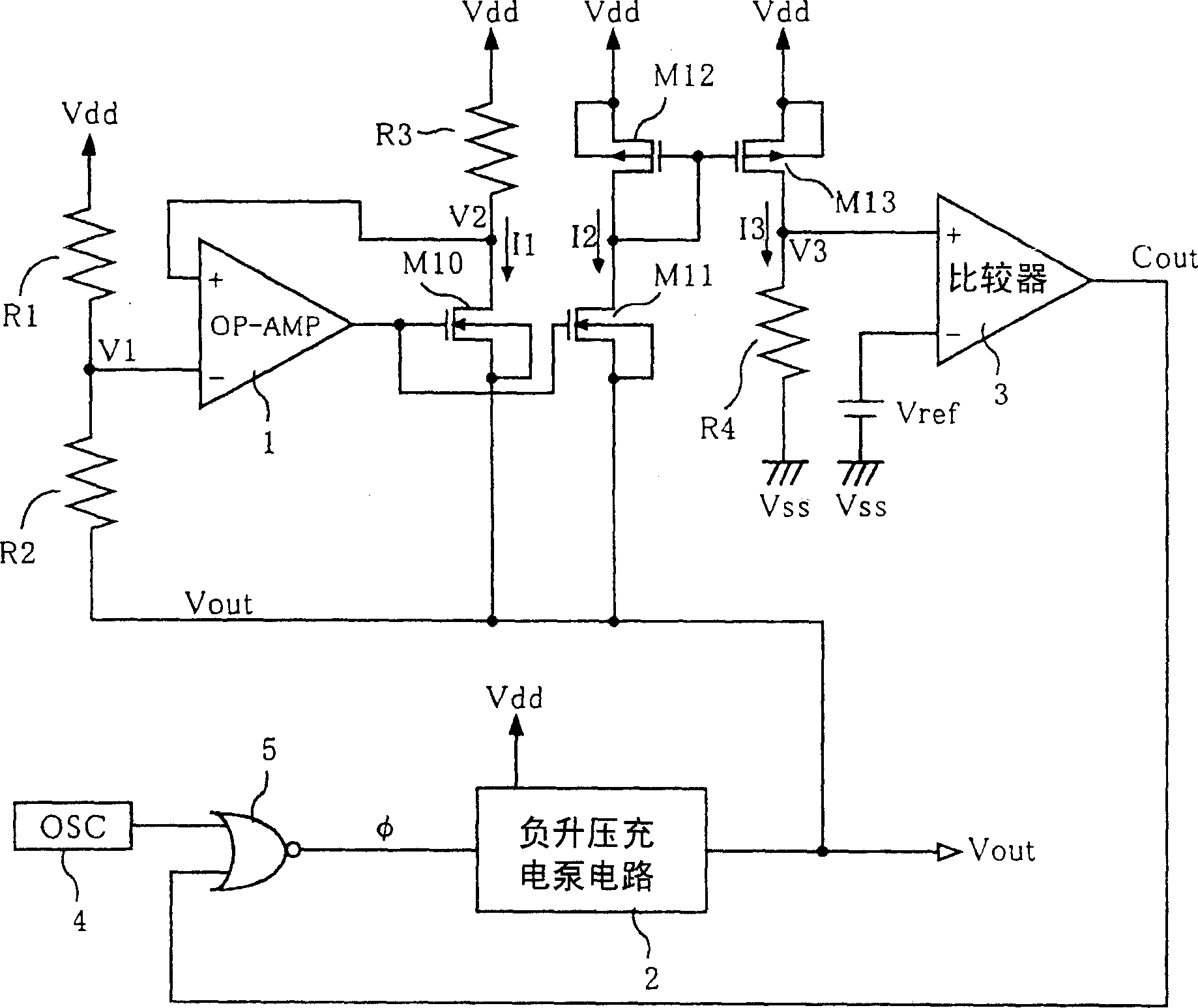

[0033] Before describing the embodiment of the present invention, an overvoltage prevention circuit related to a reference example will be described. Figure 10 is the circuit diagram of this overvoltage prevention circuit. Resistors R1 and R2 are connected in series between the output voltage Vout (<0V) and Vdd of the charge pump circuit 60 for negative boosting, and a voltage V0' is generated at the connection point, and the voltage V0' and the following voltage are generated by the comparator 61. Vout is compared with a reference voltage (Vref+Vout) as a reference, and the output of the comparator 61 controls the supply of the boost clock φ to the charge pump circuit 60 .

[0034]That is, when V0'>Vref+Vout, the output of the comparator 61 is H (high), and the boost clock φ is supplied to the charge pump circuit 60, so the charge pump circuit 60 performs a boost operation.

[0035] According to the boosting operation of the charge pump circuit 60, when V0'

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com