Keyhole sartorius

A sewing machine and buttonhole technology, which is applied to sewing machine components, sewing machine casings, sewing equipment, etc., can solve the problems of sewing obstacles, heating of the driving part, insufficient supply of lubricating oil, etc., and achieve the effect of rapid recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

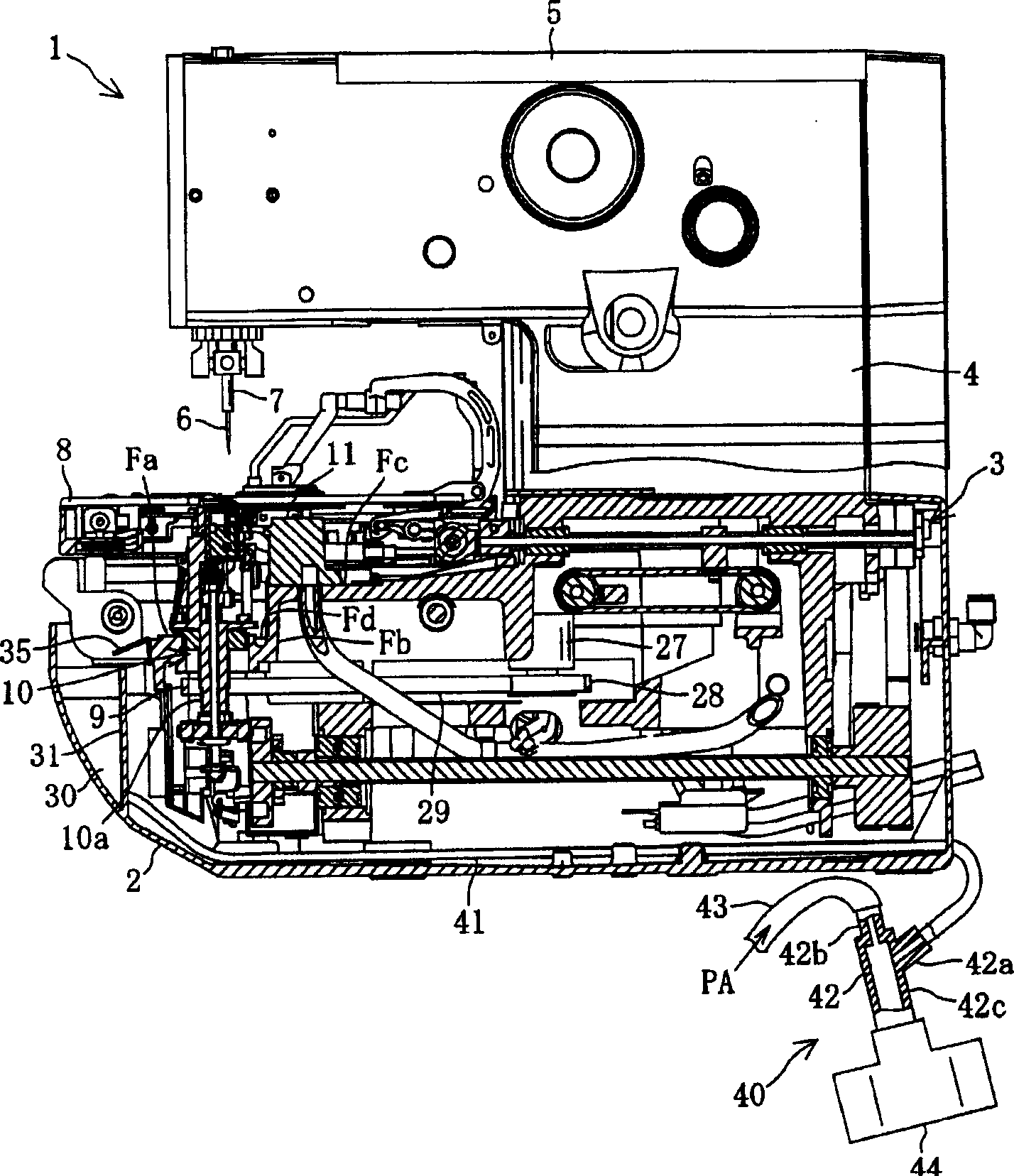

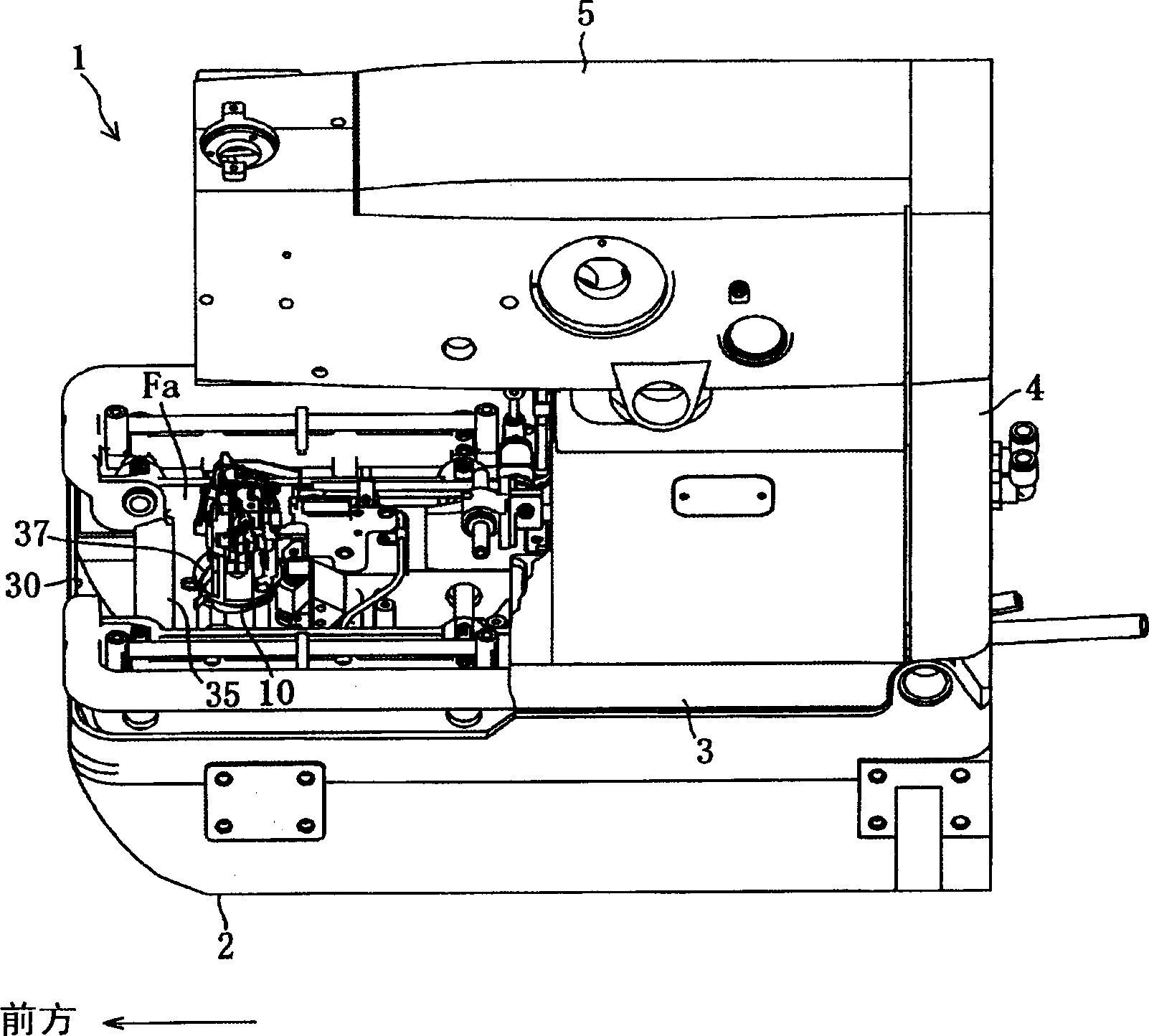

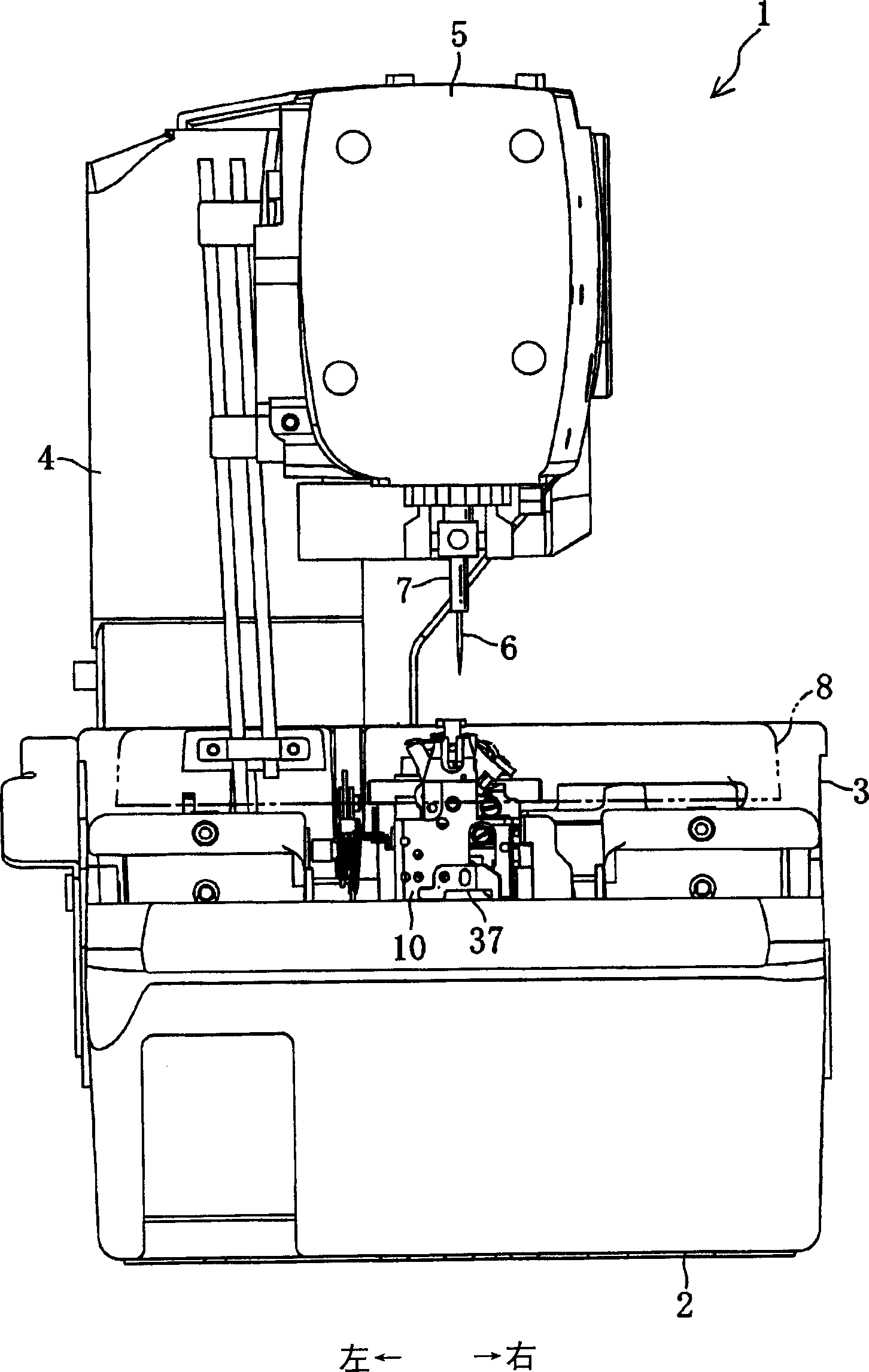

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below with reference to the accompanying drawings showing preferred embodiments.

[0029] The buttonhole sewing machine shown in the figure has a thread recovery chamber integrally formed inside the front end of the machine base, and the thread ends generated by cutting the end of the thread by the thread cutting device are sent out by the rotation of the looper base, and recovered into the thread recovery chamber.

[0030] Such as Figure 1 ~ Figure 3 As shown, the buttonhole sewing machine 1 has: a rectangular box-shaped machine base 2 with an open upper part, a bottom plate 3 placed on the open part of the machine base 2 in an embedded shape, and a column 4 erected from the rear surface of the bottom plate 3 , and a casing 5 extending forward from the top of the column 4, the buttonhole sewing machine 1 is placed and fixed on a sewing machine table not shown.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com