Method for making multi-channel stealth pattern on metallic material surface

A technology of metal materials and production methods, applied in the fields of crafts for producing decorative surface effects, processing of photosensitive materials, special patterns, etc., can solve problems such as corrosion, and achieve the effect of simple production methods, low cost, and high artistic appreciation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Example 1 of this method: making the allotropic invisible effect of "50" and "fifty"

[0048] The computer designs mentioned in this example are all made in coreldraw9.0 software. But it can be done in other computer graphic design software using the same production method and principle.

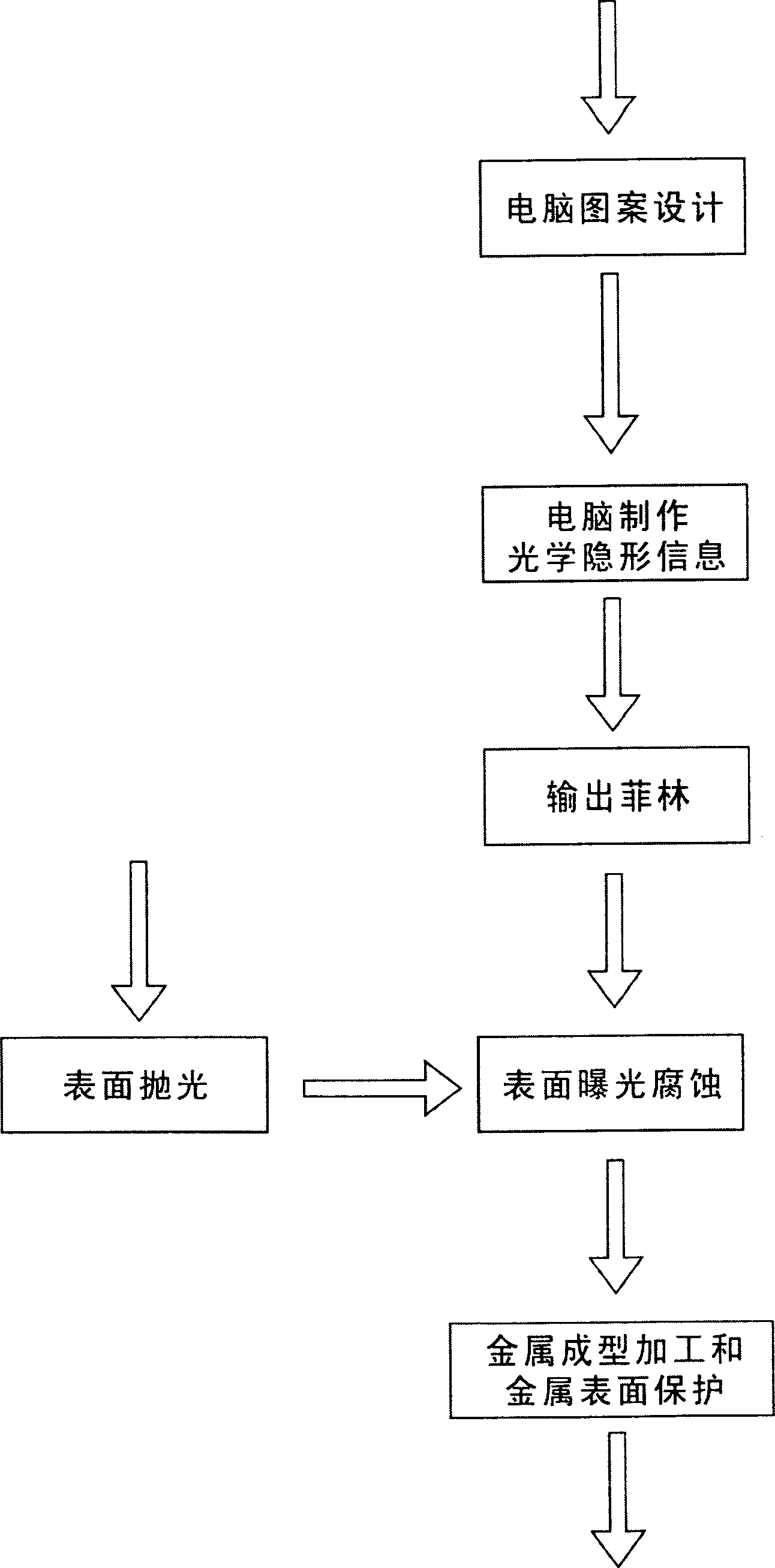

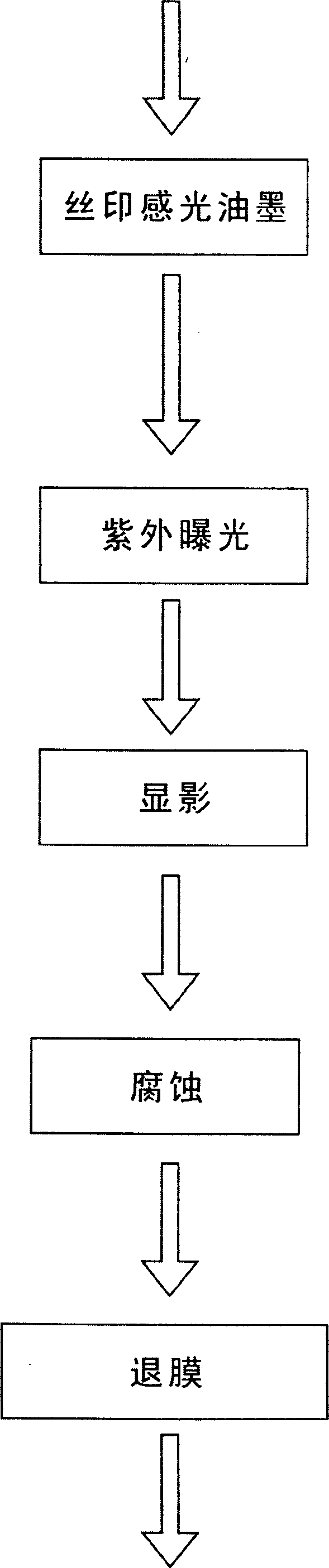

[0049] The production process is as follows (see attached figure 1 , 2 )

[0050] 1. Computer graphic design

[0051] This work is a known technology of computer graphic design, and any computer graphic design production staff can complete this work.

[0052] The main purpose of this work is to design the pattern that needs to be formed on the metal surface.

[0053] The designed patterns are saved in different picture formats according to different design software, for the next step of operation.

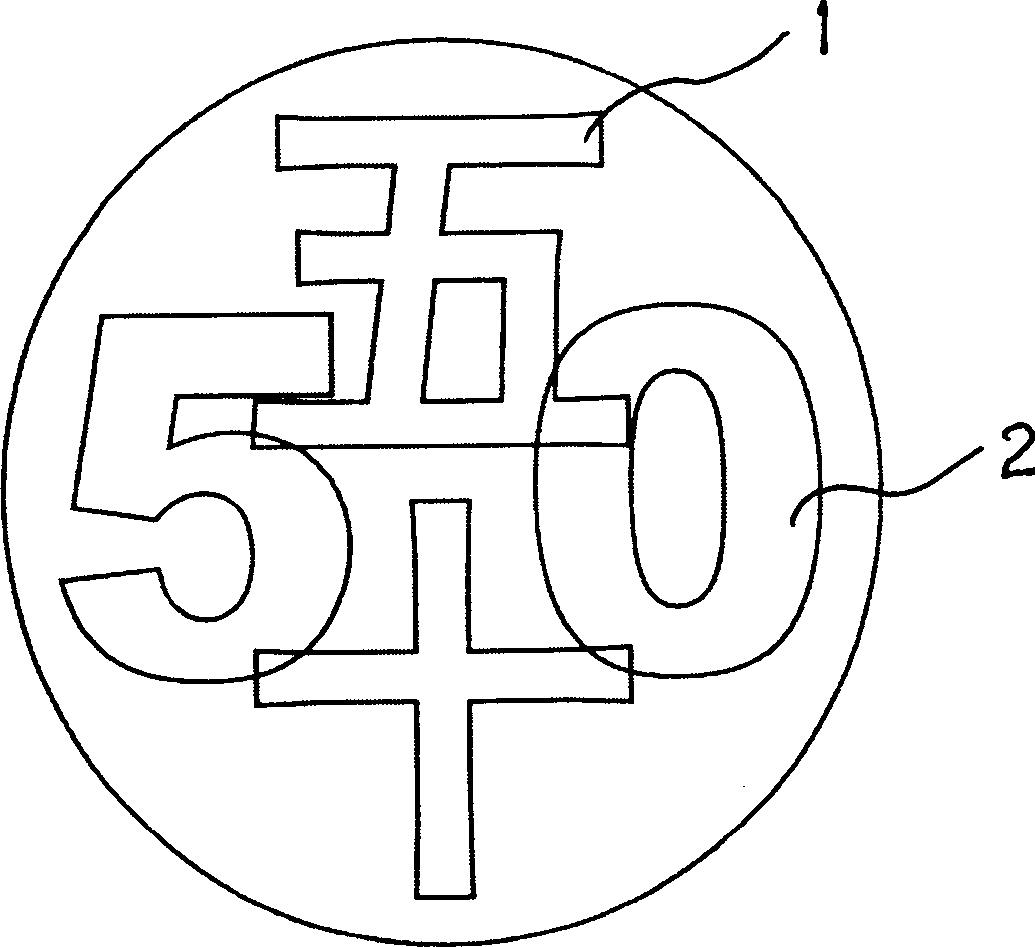

[0054] Example: Design a circle, there is a number "50" in the circle, and another Chinese character "fifty", the two numbers are interlaced, (such as image 3 shown)

[0055] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com