Electron emission device

A technology of electron emission device and electrode, which is applied in the direction of photoelectric emission cathode, tube without control device, circuit, etc., to achieve the effect of high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

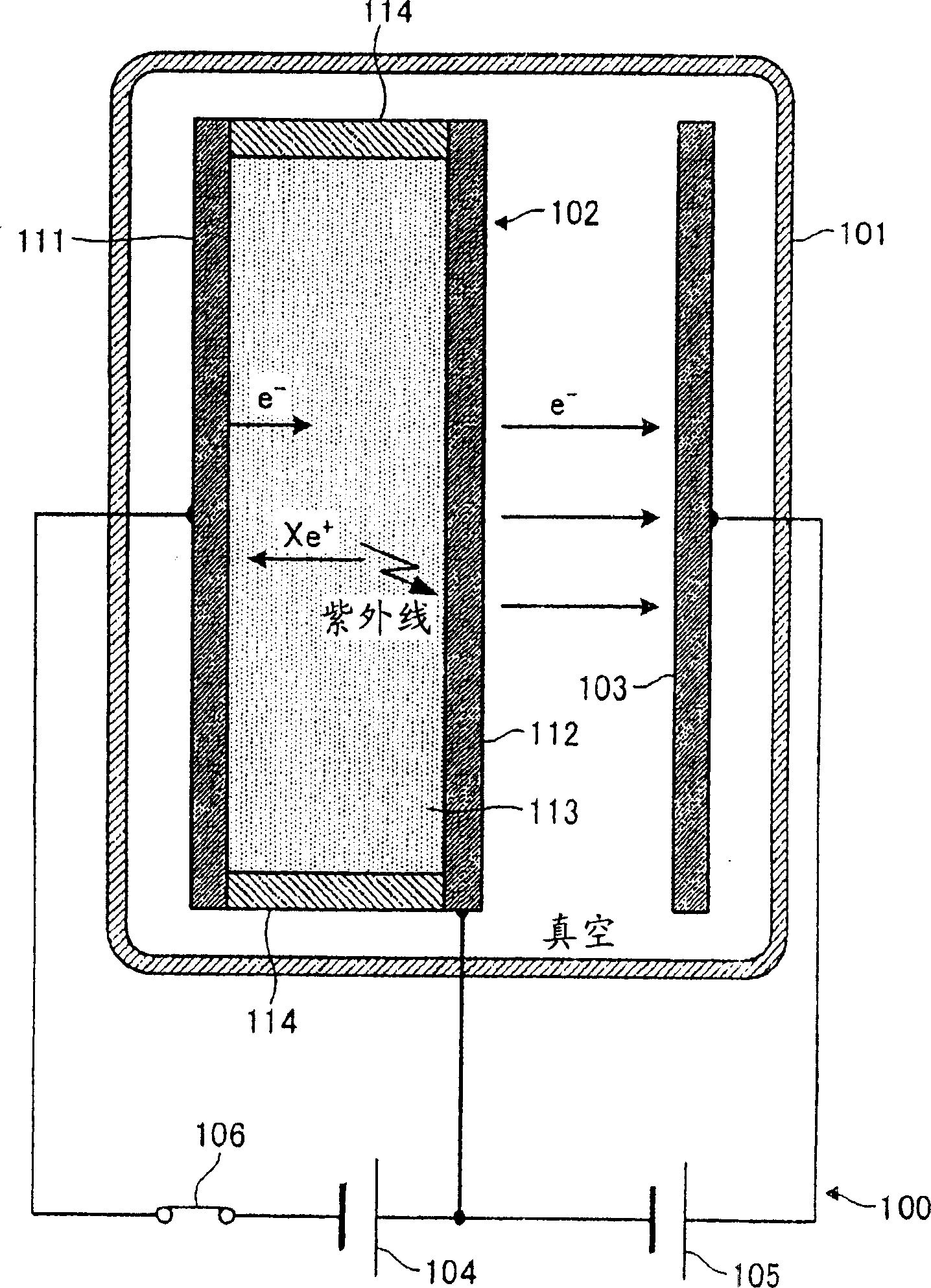

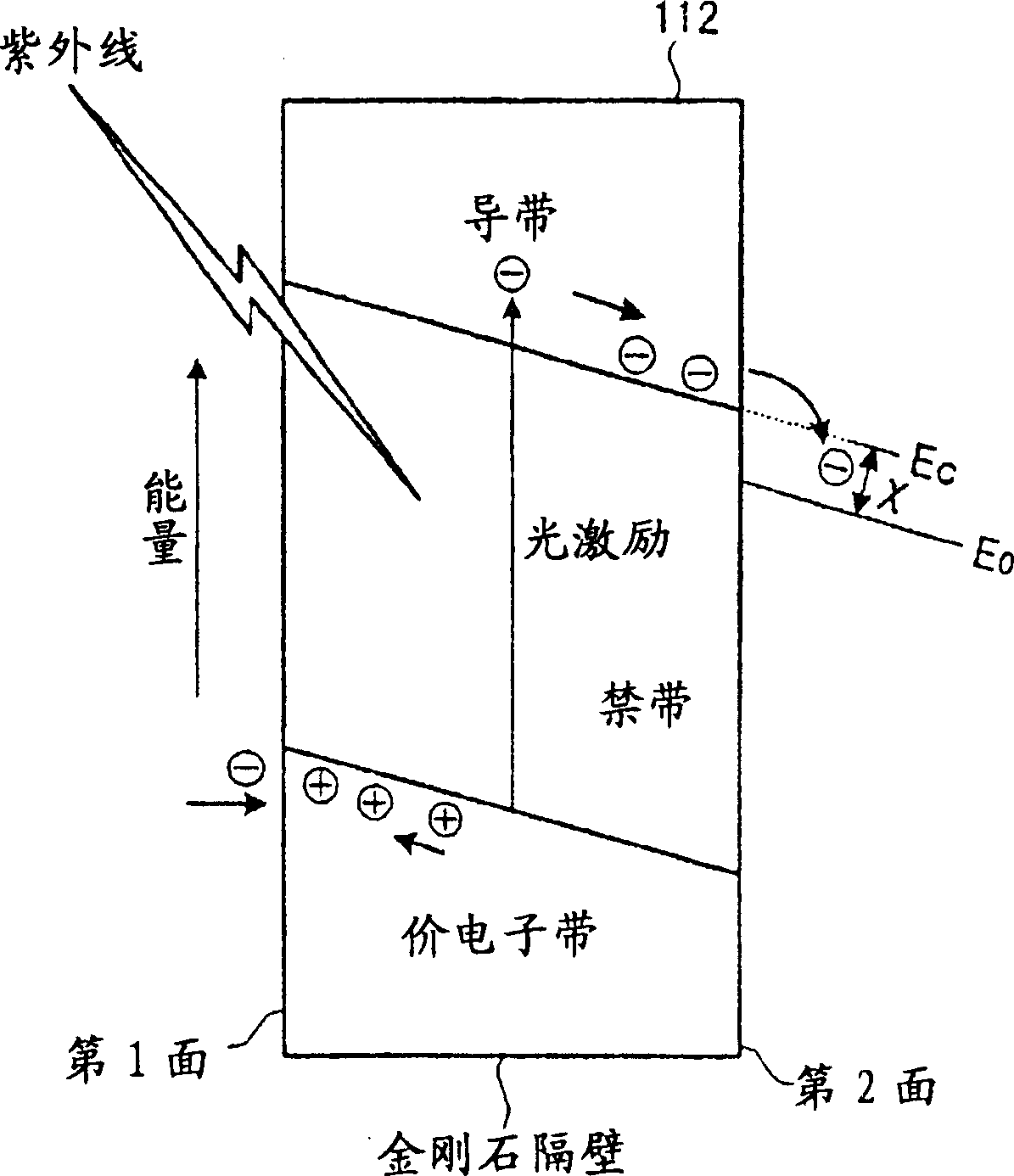

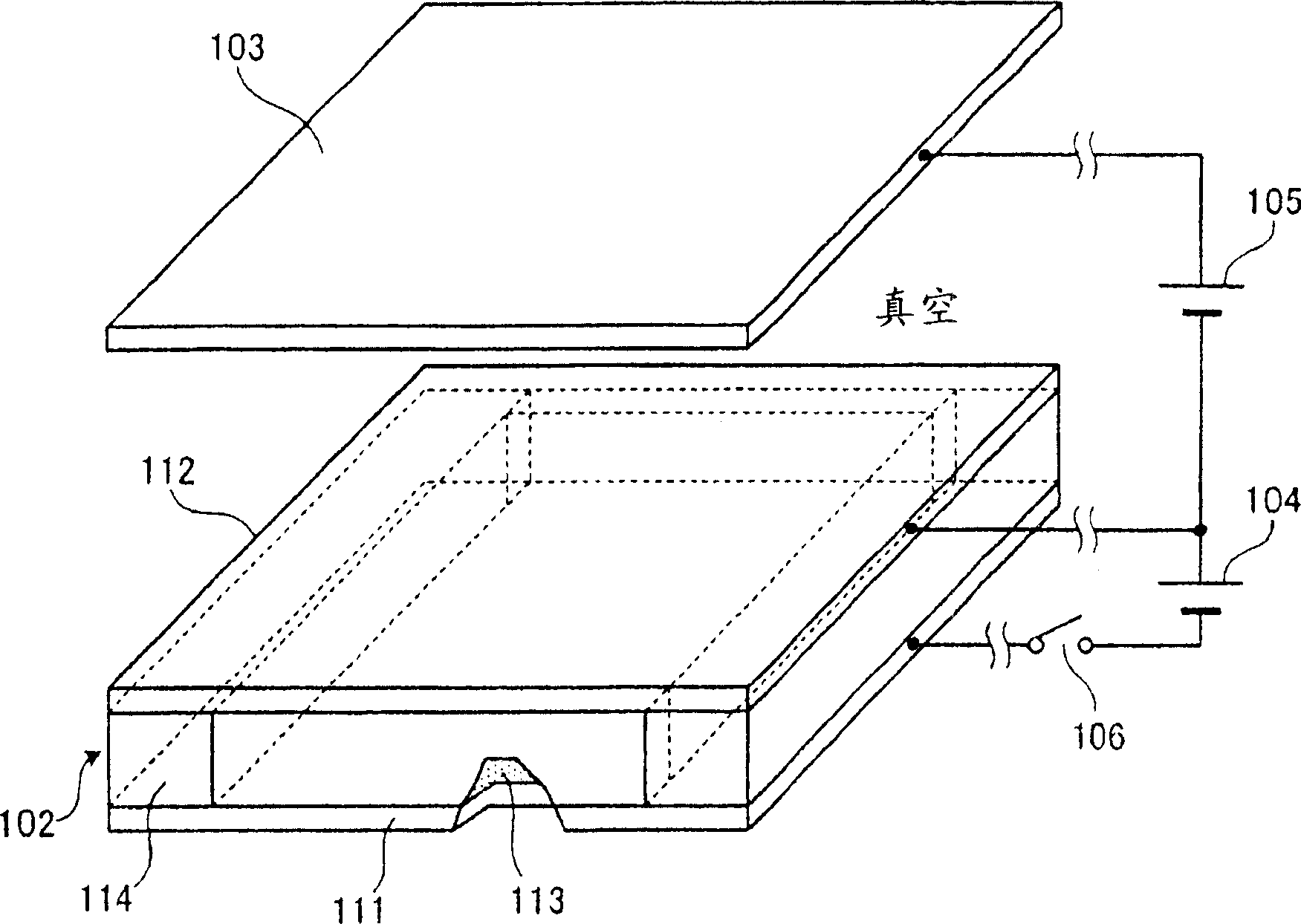

[0028] figure 1 It is a side cross-sectional view of the electron emission device 100 of the first embodiment. As shown in this figure, the electron emission device 100 has a discharge unit (cell) 102 and a discharge anode 103 inside a vacuum airtight container 101, and has an off switch 106 and a first power supply 104 outside the airtight container 101. and the second power supply 105 . In addition, since this figure is prepared for ease of explanation, the dimensional ratios in the figure are not necessarily consistent with the description or other Figure 1 Sincerely.

[0029] The airtight container 101 forms a vacuum inside the container for emitting electrons in the vacuum. The shape, size, and material of the airtight container 101 are not limited as long as the container can be vacuumed. For example, in the case where a phosphor is coated on the discharge anode 103, it is also possible to make the emitted electrons collide with the phosphor so that the user can see...

no. 2 Embodiment approach

[0060] In addition, the electron emission device 100 according to the first embodiment generally does not control when emitting electrons after the power supply circuit is turned on by the switch 106 for shutting off. However, the present invention is not limited to such a configuration, and may have a configuration for efficiently starting electron emission, and use this configuration to perform control at the time of electron emission. Therefore, in the second embodiment, a case where a trigger switch is provided and the current on the control circuit is switched by the trigger switch will be described.

[0061] Figure 5 It is a side cross-sectional view of the electron emission device 500 of the second embodiment. The difference from the electron emission device 100 of the first embodiment described above is that it has a configuration in which a trigger switch 501 is added. In the following description, the same reference numerals are assigned to the same constituent el...

no. 3 Embodiment approach

[0067] In the electron emission device of the above-described embodiment, the amount of emitted electrons can be adjusted only by using the off switch 106 to perform on / off control of electron emission. However, the present invention is not limited to such control, and a mechanism for controlling the amount of current, that is, the amount of electron emission may be provided. Therefore, in the third embodiment, a case where the emission amount of electrons is controlled by providing a variable resistor will be described.

[0068] Figure 7 It is a side cross-sectional view of the electron emission device 700 of the second embodiment. The difference from the electron emission device 500 of the second embodiment described above is that it has a structure in which a variable resistor 701 is added and an off switch 702 is arranged differently from the off switch 106 . In the following description, the same reference numerals are assigned to the same constituent elements as those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com