Method for increasing yield of tobacco slices in sheet tobacco prodn. line

A production line and tobacco sheet technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of reducing production efficiency and slow operation of the production line, and achieve the effects of increasing slice production, reducing processing time, and increasing the speed of action convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

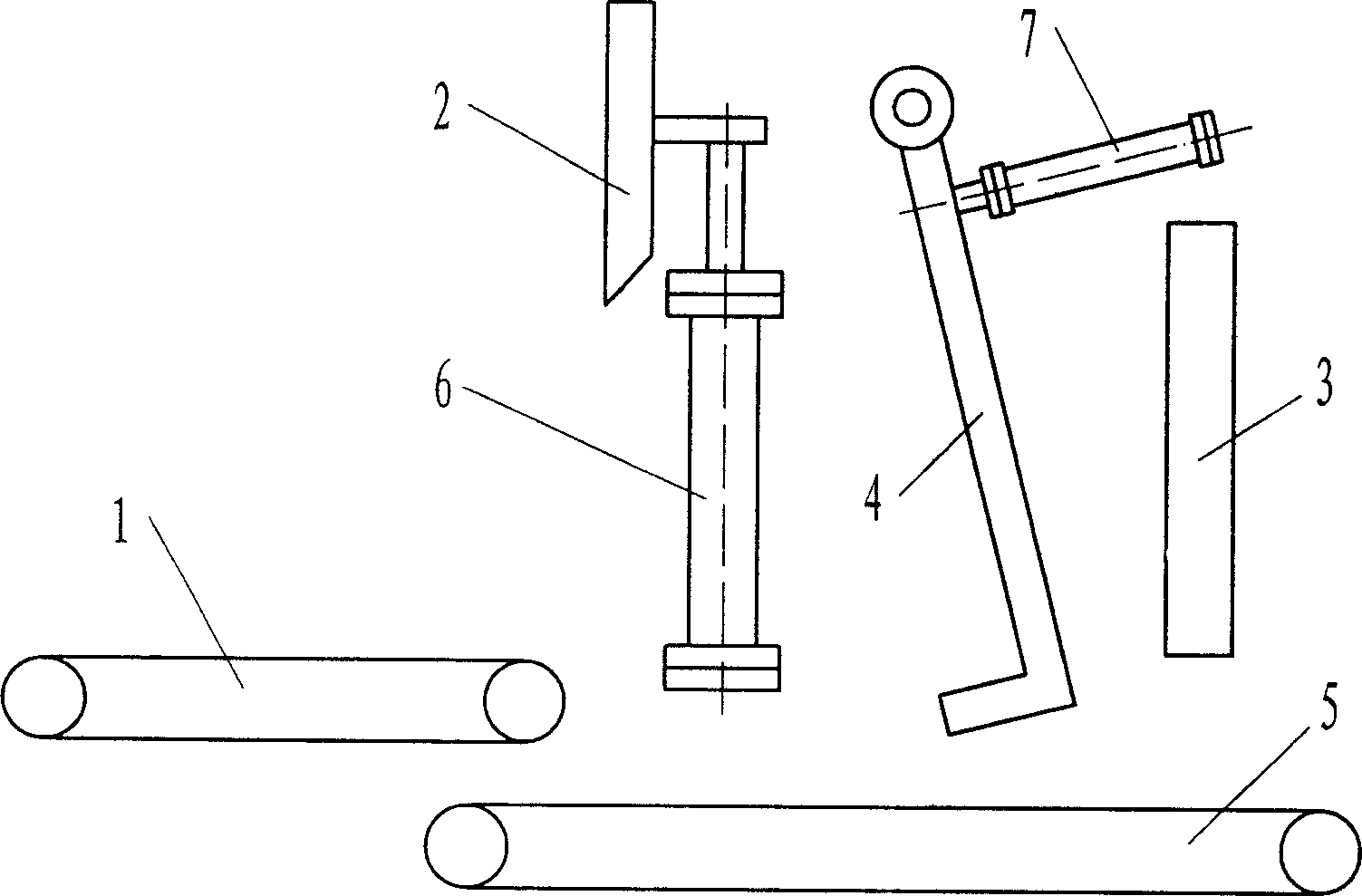

[0014] The part of the action performed by cutting the shredded tobacco sheet and the tobacco thread is shown in the accompanying drawings, and its structure and action relationship have been described in the background technology, and will not be repeated here. The present invention improves slice output of the tobacco production line through the technical measures in the following four aspects.

[0015] (1) Control the speed of the feeding conveyor belt 1, and use a frequency converter to adjust the speed of the conveyor belt 1 to make it run at different speeds in different stages.

[0016] When the feeding conveyor belt 1 detects that there is a cigarette packet at the entrance, the motor runs at a high speed at the highest set frequency to save the conveying time; when it is close to the position of the cutter, the photoelectric cell in front of the cutter detects the Finally, the feeding conveyer belt 1 changes to a low-speed setting frequency and runs at a low speed, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com