Manufacturing equipment of hot pipe device and its application

A technology for manufacturing equipment and devices, which is applied to heat pipe device manufacturing equipment and its application fields, can solve the problems of low production cost, long vacuuming time, increased processing steps, etc., and achieves high vacuum retention, high degree of automation, and simple equipment structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

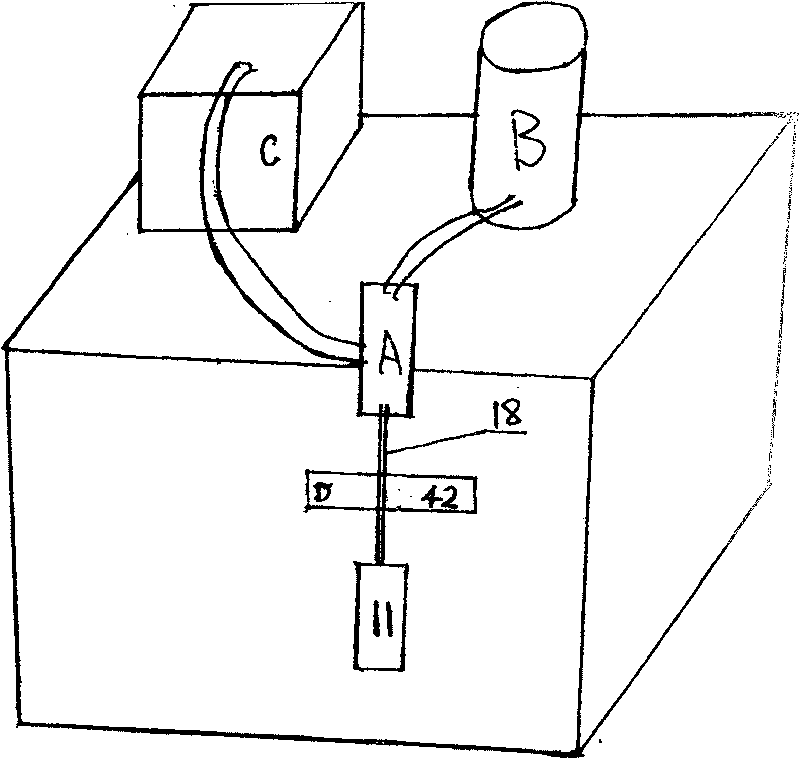

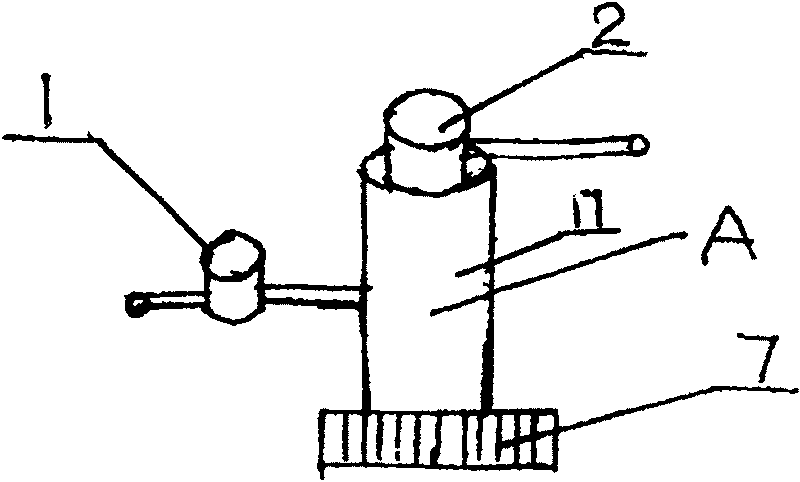

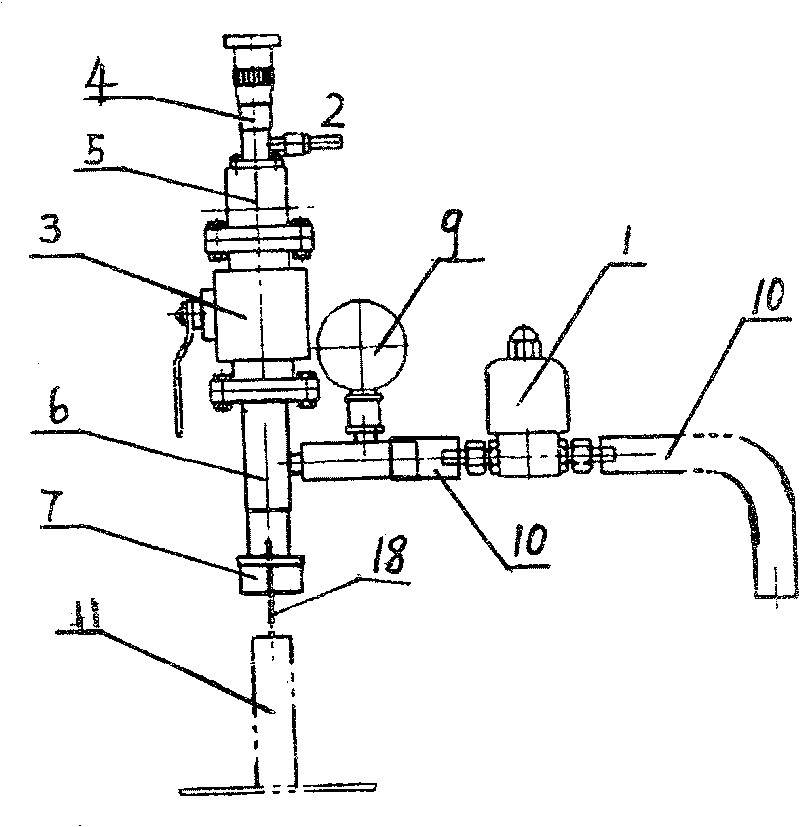

[0037] see figure 1 , a heat pipe device manufacturing equipment is characterized in that: it is composed of at least one vacuum filling valve group A, at least one working medium filling system B, at least one vacuum obtaining device C, and at least one sealing device D, and the vacuum obtaining device C The vacuum valve 1 is connected to the chamber of the vacuum filling valve group A, the working medium filling system B is connected to the chamber of the vacuum filling valve group A through the valve 2, and the sealing clamp of the sealing device D is located in the vacuum filling At the bottom of the valve group A, the vacuum filling tube 18 of the processed workpiece 11 is inserted into the inside of the rubber ring 16 through the clamping ring 7, and the processed workpiece 11 is connected with the vacuum filling valve group A by tightening the clamping ring 7. Airtight, the sealing device D is located at the bottom of the clamping ring 7, and the vacuum filling tube 18 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap