Automatic loading-unloading method of pallet type lifting machine and its device

A technology of automatic loading and unloading and hoisting, which is applied in the direction of conveyor control device, loading/unloading, conveyor objects, etc., can solve the problems of small space of hoist, unable to unfold, safety accidents, etc., to improve labor intensity and labor conditions, improve production efficiency and production safety, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

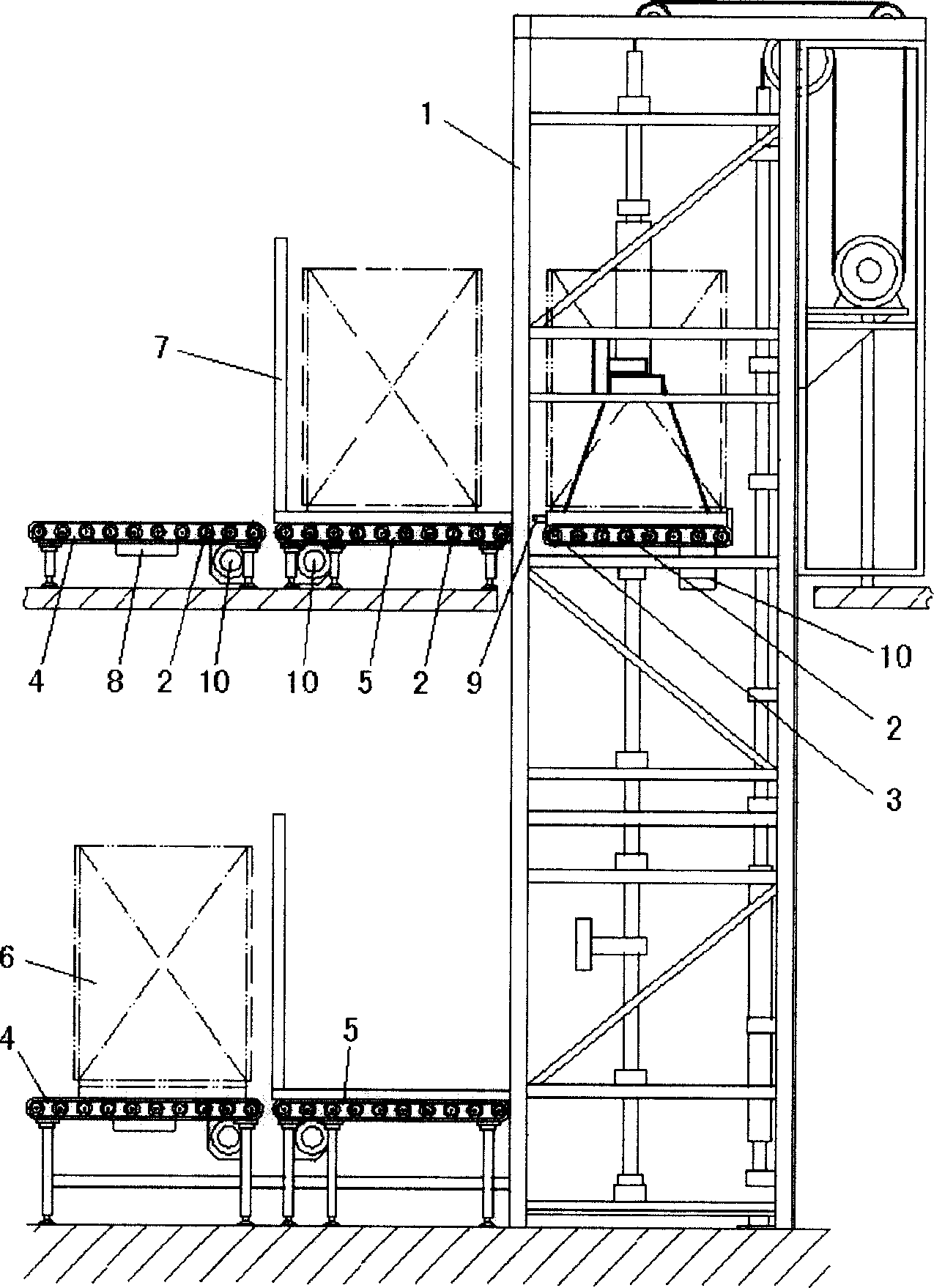

[0013] Embodiment of the present invention: when adopting the automatic loading and unloading method of a kind of pallet elevator of the present invention to implement, as figure 1 As shown, a power load trolley 3 with a power-driven roller 2 is installed on the hoist 1, and two power roller units with a power-driven roller 2 are installed at the entrance and exit of each floor, one is the front-stage power roller The other column unit 4 is the rear-stage power roller column unit 5; when loading, put the palletizing pallet 6 on the front-stage power roller column unit 4, and the palletizing pallet 6 will automatically move to the On the power load trolley 3 in the hoist 1, the hoist 1 drives the power load trolley 3 to rise to the required floor; when unloading on another floor, the palletizing tray 6 is automatically stacked under the drive of the power drive roller 2 The pallet 6 moves from the power load trolley 3 in the hoist 1 to the front-stage power roller unit 4 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com