Precast stairway system, unit structure thereof, and method of constructing stairway system using the same

A technology for unit structures and stairs, applied in the direction of ladder-like structures, stairs, building construction, etc., can solve the problems that have not been proposed to meet the economic efficiency, practicality and quality characteristics of suitable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following, several preferred embodiments of the present invention will be described with reference to the corresponding drawings. In the following description and drawings, the same or similar components are denoted by the same reference numerals, so that repeated descriptions of the same or similar components are omitted.

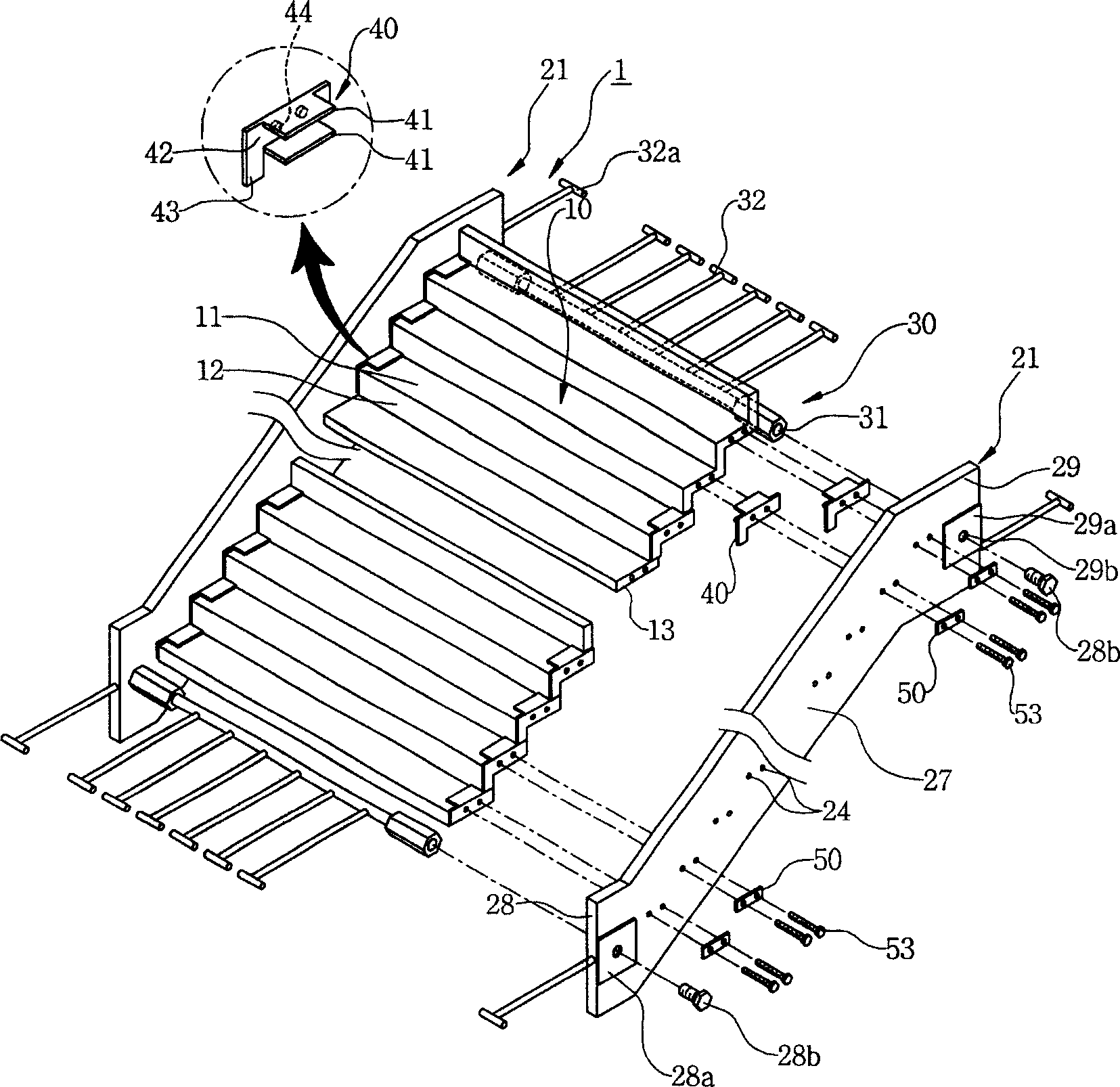

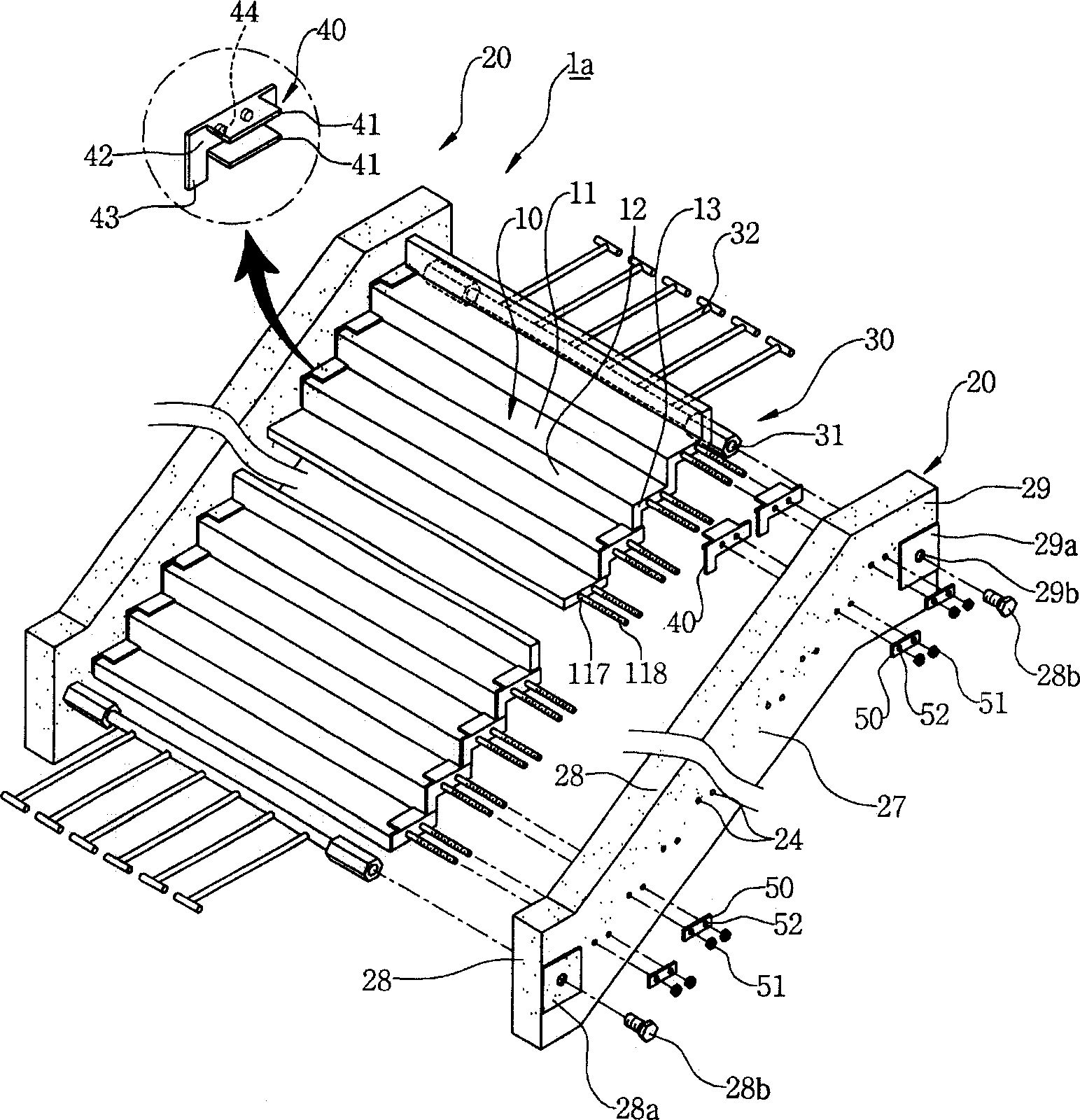

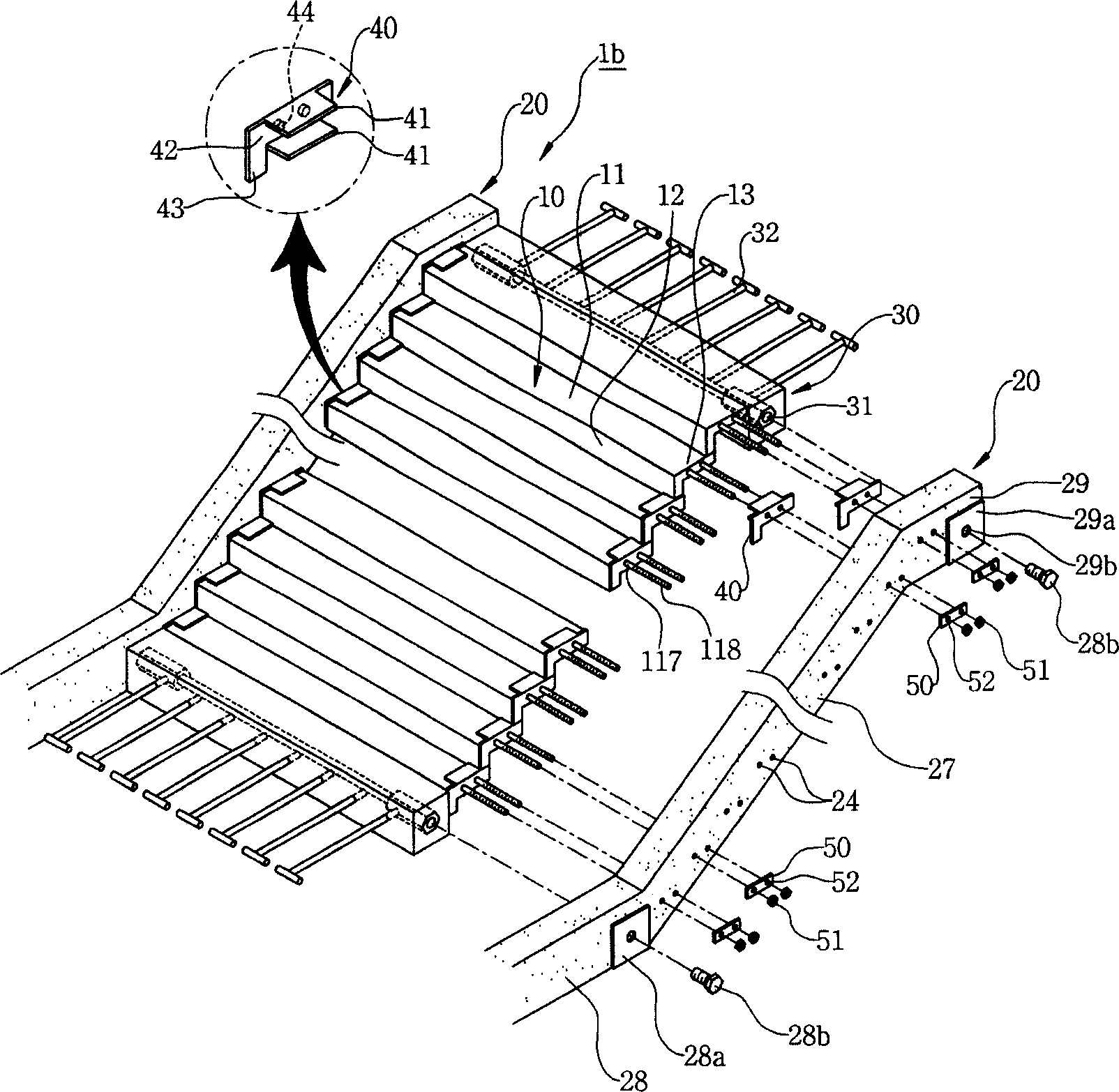

[0038] Figure 1 to Figure 3 is an exploded perspective view showing a high-strength or ultra-high-strength fiber cement composite prefabricated staircase system 1, 1a and 1b according to a preferred embodiment of the present invention, in which some parts are omitted. Since the basic structures of the prefabricated staircase system are consistent with each other, they will be described simultaneously for the convenience of description.

[0039] The prefabricated stair system 1, 1a or 1b comprises a stair 10 and two inclined stair bases 20 (optionally, an inclined concrete stair base 20 and an inclined iron stair base 21) respectively positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com