Bridge erection method

A technology for bridges and beams, which is applied in the field of bridge erection after simple support first and then continuous, can solve the problems of construction and dismantling cost, labor and material, high requirements for support stability, affecting the clearance under the bridge, etc., and achieves convenient construction and driving comfort. good, holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

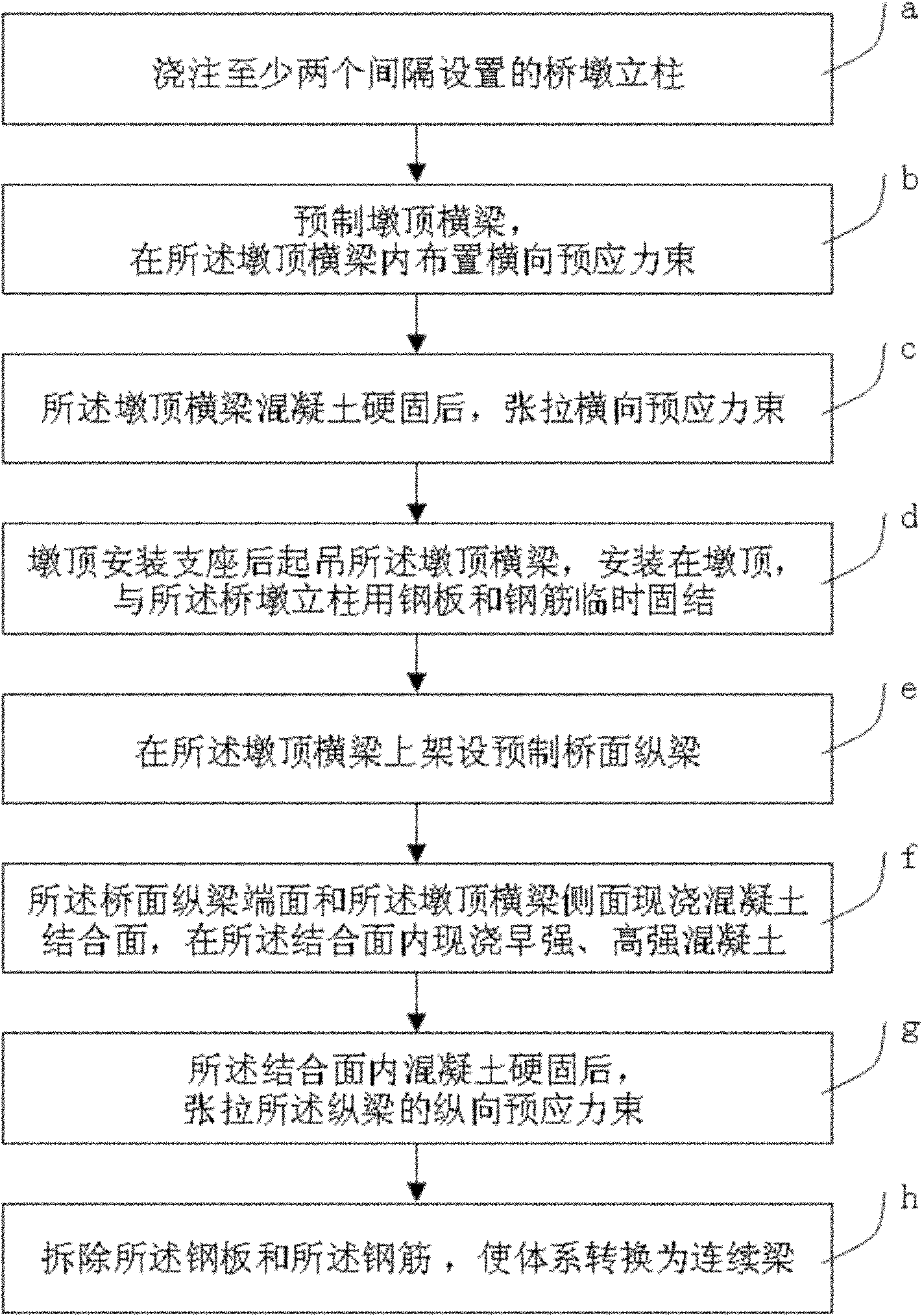

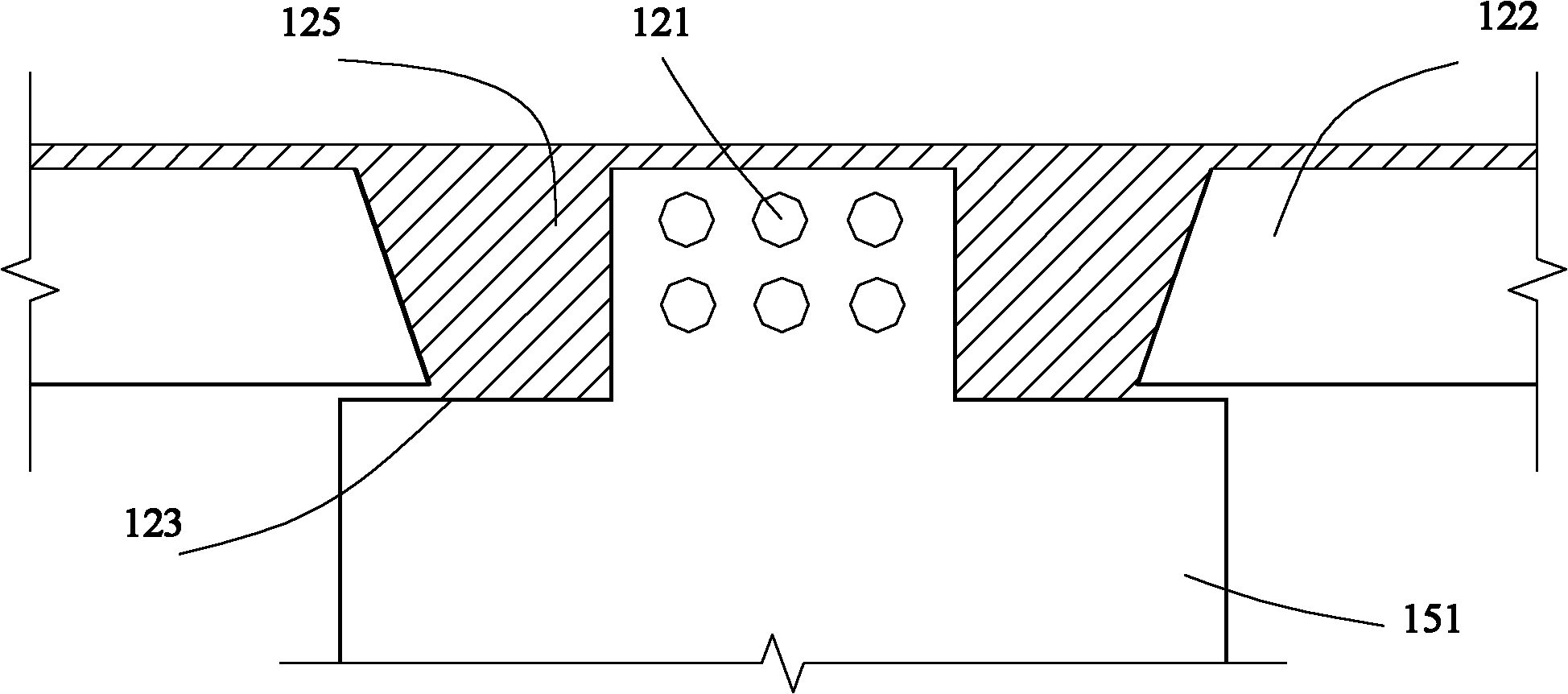

[0030] Such as figure 1 , is a flow chart of a bridge erection method provided by the present invention. Such as figure 2 , image 3 , Figure 4 and Figure 5 Shown, this bridge erecting method comprises the following steps:

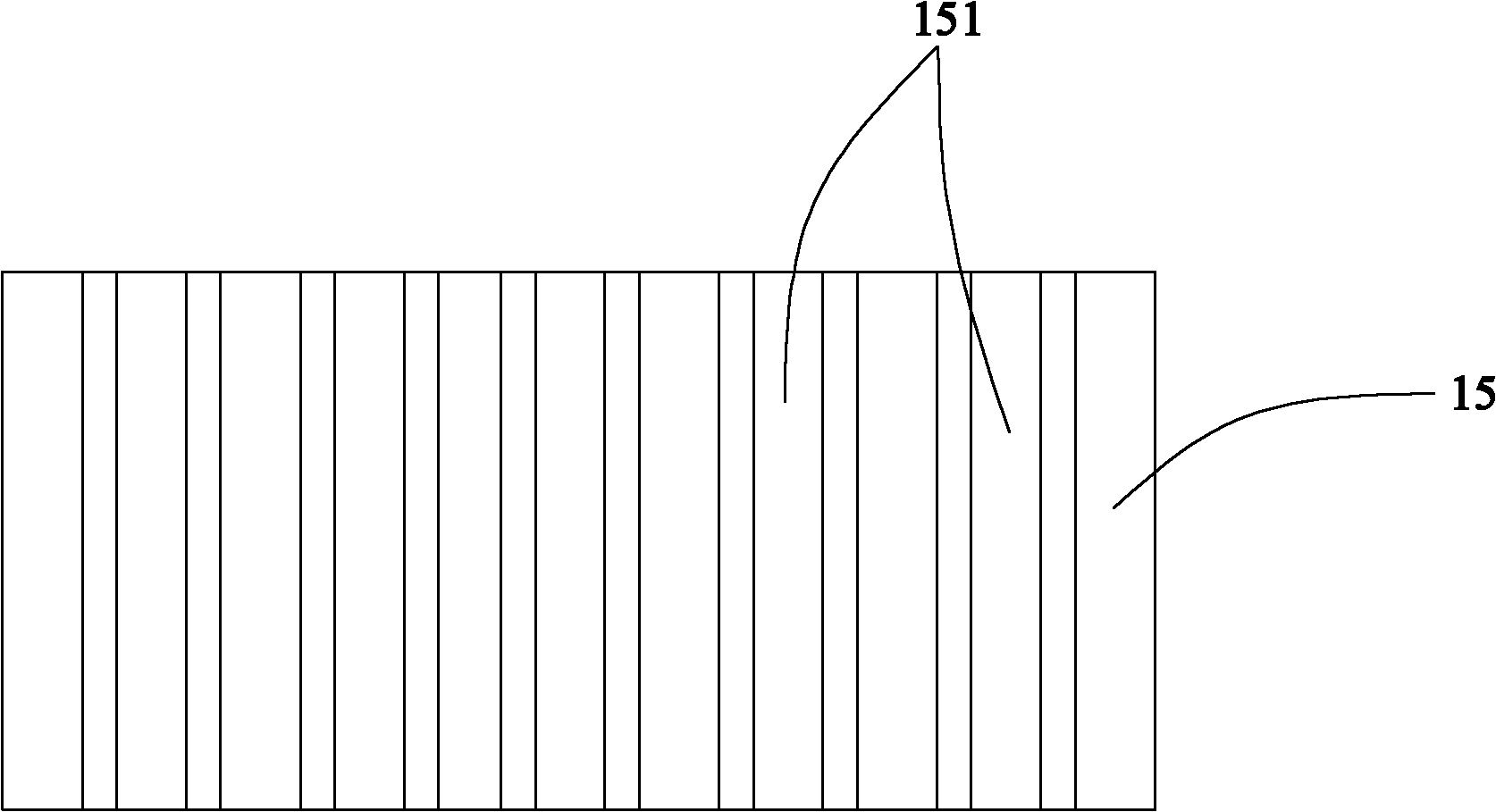

[0031] The cross-section of the prefabricated pier top beam 15 is inverted T-shaped 151, the beam height is slightly lower than the longitudinal prestressed beam, the inverted T-shaped cantilever 123 on the bottom surface can support the bridge deck longitudinal beam 122, the end surface of the bridge deck longitudinal beam 122 and the side surface of the inverted T pier top beam 151 are The cast-in-place concrete joint surface 125, the shear key on the joint surface 125 is composed of a plurality of rectangular or elongated key blocks (grooves), and the transverse prestressed beam 121 is arranged in the top beam of the inverted T pier according to the design requirements.

[0032] After the concrete of the prefabricated pier top beam 15 reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com