Heat-preservation precast wall body and assembled house

A prefabricated wall and wall technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of low construction quality, difficulty in hanging objects, and easy falling off of insulation materials, so as to improve construction quality, save construction time, and keep heat preservation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

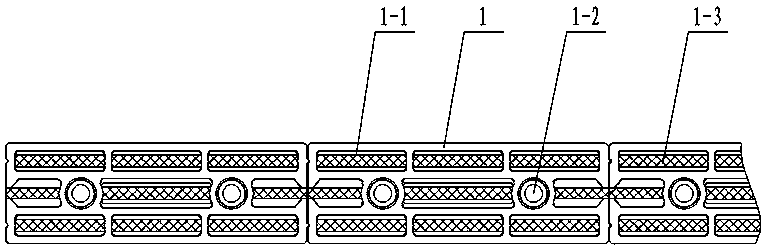

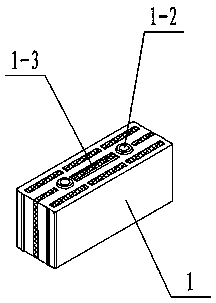

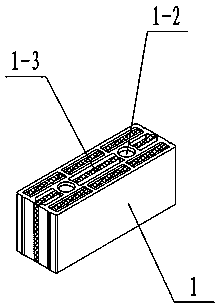

[0050] The thermal insulation prefabricated wall body of this embodiment, as Figure 1 to Figure 5 As shown, the thermal insulation prefabricated wall body is a piece of wall body formed by building blocks 1 from bottom to top before the construction of the existing wall. The block 1 is formed with a cavity 1-1 and a small post hole 1-2 that penetrates the block body along its height direction, and the cavity 1-1 is a row of cavities that penetrate the block body along the height direction of the block 1. One row of cavities, three rows of cavities, and even more rows of cavities.

[0051] The cavity 1-1 and the small column hole 1-2 in each layer of building blocks 1 communicate with the cavity 1-1 and the small column hole 1-2 in the adjacent layer of building blocks built up and down. The cavity 1-1 is used for pressing the column steel pipe, pressing the column steel bar or clamping the insulation sheet 1-3.

[0052] Concrete is filled in the cavity provided with column ...

Embodiment 2

[0061] The thermal insulation prefabricated wall body of this embodiment is an improvement on the basis of Embodiment 1, such as Figure 12 and Figure 13 As shown, the difference from Embodiment 1 is that the thermal insulation prefabricated wall is a piece of wall cut from sand aerated concrete block in advance before the existing wall construction. Small grooves 1-4 are arranged on the inner and outer sides of the piece of wall in a grid shape, and a plurality of through holes 1-5 that run through the inner and outer sides of the piece of wall are arranged on the piece of wall. High-strength concrete is cast in grooves 1-4.

[0062] The piece of wall is provided with at least one steel bar for hoisting and assembling the piece of wall, and the steel bar is inserted and fixed in the high-strength concrete in the small groove 1-4.

Embodiment 3

[0064] The thermal insulation prefabricated wall body of this embodiment is an improvement on the basis of Embodiment 1 and Embodiment 2, such as Figure 14 to Figure 16 As shown, the difference from Embodiment 1 is that the thermal insulation prefabricated wall is a piece of wall prefabricated before the existing wall construction, and at least one column steel pipe is arranged longitudinally in the piece of wall.

[0065] The wall body is composed of outer concrete thin-slabs 1-6, sound-reducing insulation layers 1-7 and inner concrete thin-slabs 1-8 arranged sequentially from outside to inside. Light aggregate concrete connection columns 1-9 are arranged at intervals in the wall, and the light aggregate concrete connection columns 1-9 pass through the sound-reducing insulation layer 1-7, and the inner concrete thin-slab body 1-8, the outer concrete thin-slab The board body 1-6 and the sound-reducing insulation layer 1-7 are connected and fixed into one body.

[0066] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com