Pretest method for comprehensive water-containing residual oil engineering at polymer separate stage

A prediction method and staged technology, applied in earthwork drilling, production fluid, wellbore/well components, etc., can solve problems such as large prediction error and error accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

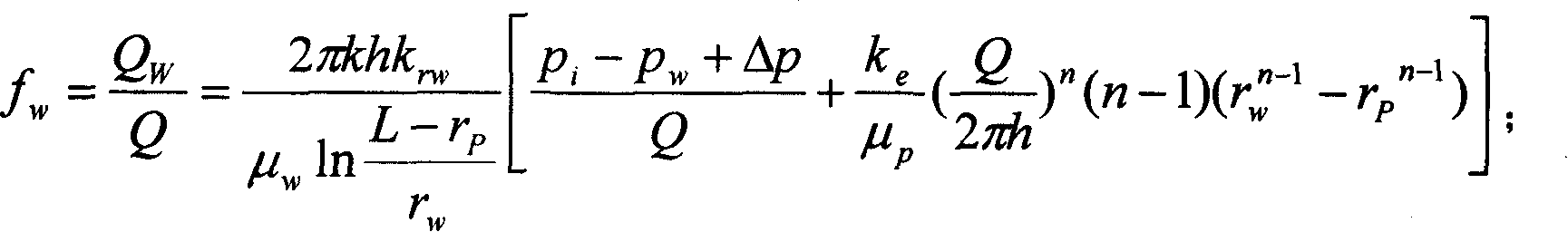

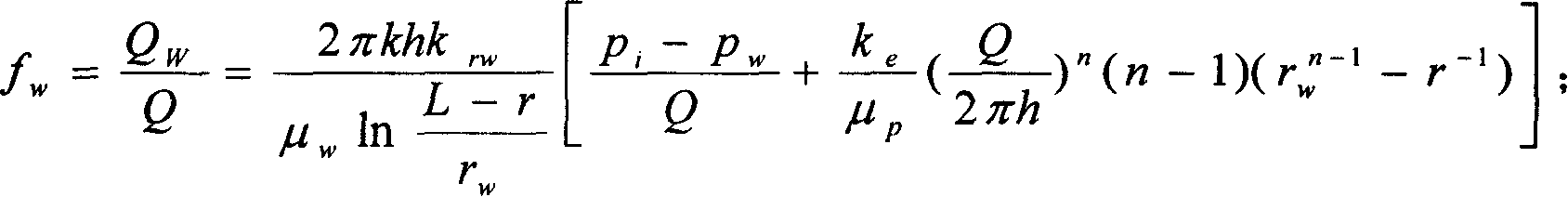

[0019] Specific implementation mode 1: In this implementation mode, according to the gradual advance of the polymer flooding slug leading edge, showing different dynamic change characteristics, the whole process of polymer flooding is divided into five stages, and a comprehensive water cut prediction model is established in stages.

[0020] The first stage is the initial stage of polymer injection in which a small polymer slug is advanced.

[0021] According to the empirical formula of Masquette, determine the relationship between the injection pressure rise and the injection volume:

[0022] Δp = Qμ P 2 πkh ln r p r w

[0023] The seepage law of the fluid in the small slug polymer solution area at the initial stage of polymer injection conforms to the g...

specific Embodiment approach 2

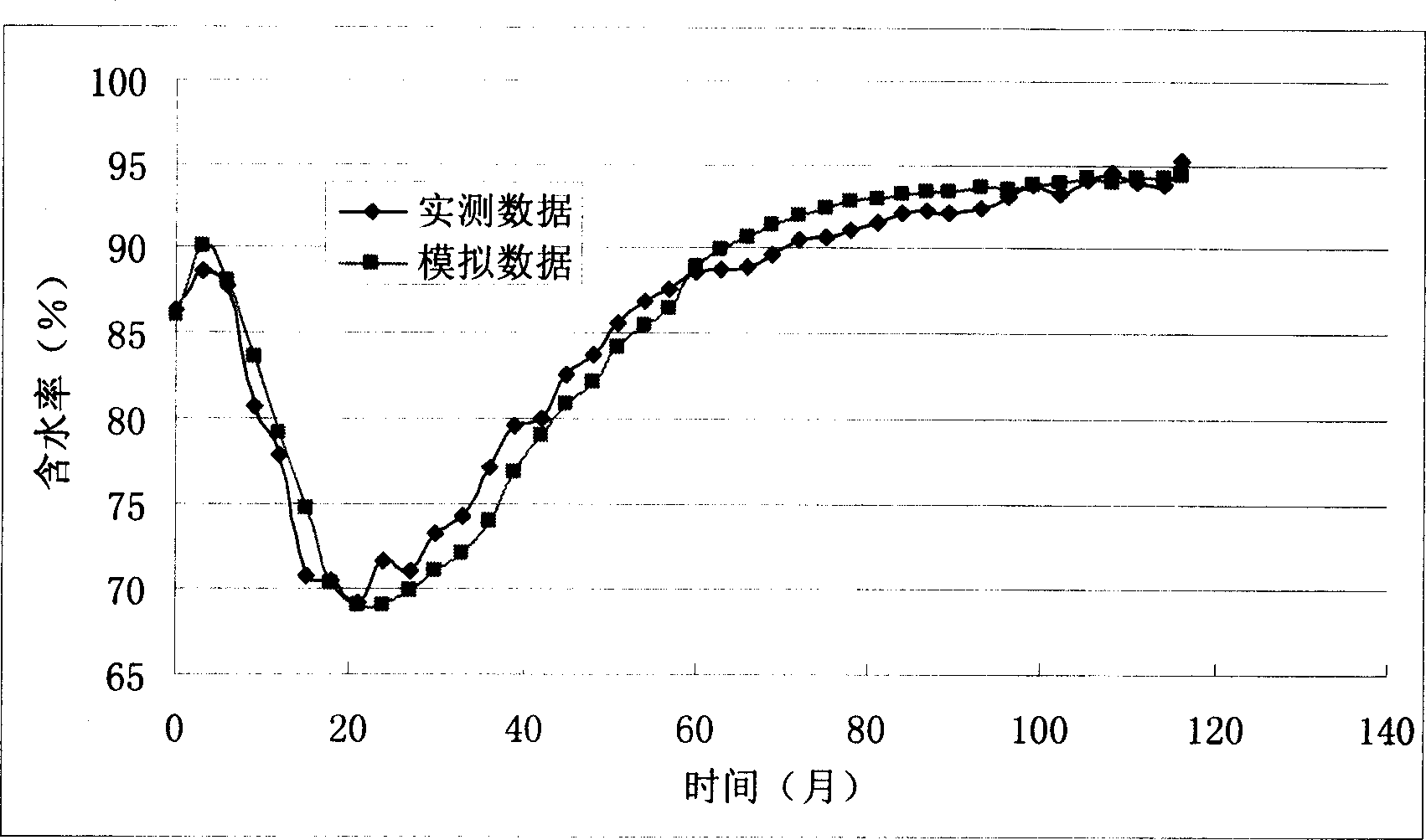

[0052] Specific implementation mode 2: Based on the above mathematical model, the comprehensive water cut in the whole process of the western eastern block of the North Second Zone of the Sabei Development Zone of Daqing Oilfield is predicted. The comparison results of numerical simulation results and oil field data are shown in figure 1 . The time for polymer injection mining in this block is about 8 years. The moisture content in the later period reaches about 95%, which belongs to the extremely high water content period. The water cut curve is relatively complete and experiences a brief water cut rise at the initial stage of polymer injection, a mid-term water cut first declines and then slowly rises, and a gentle rise in the subsequent water flooding stage. It can be seen from the figure that the numerical simulation results of the model are in good agreement with the field data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com