Electric connector of flat vibration source

A technology of electrical connectors and vibration sources, which is applied in the direction of connection, two-component connection devices, circuits, etc., can solve the problems of inconsistent installation accuracy and disappearance of height advantages, so as to reduce manufacturing costs, save manpower and material resources, and improve Effects of Consistency and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific device and implementation details proposed by the present invention will now be described in detail according to the above-mentioned drawings.

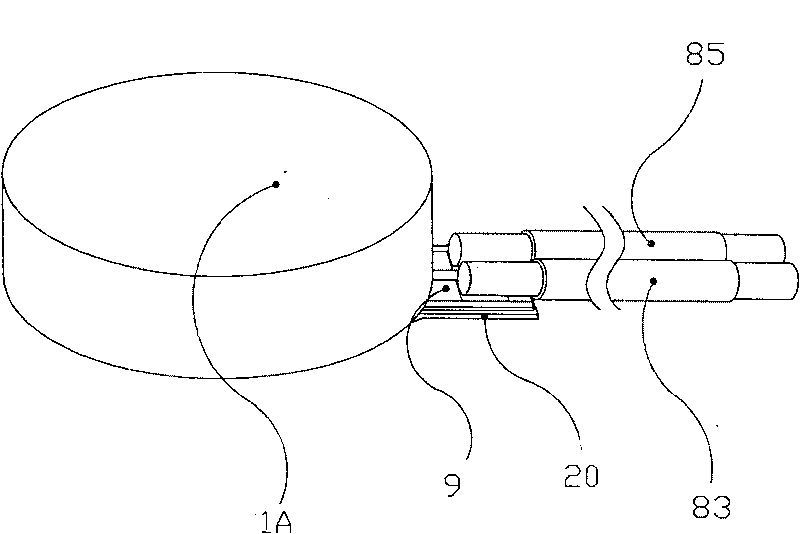

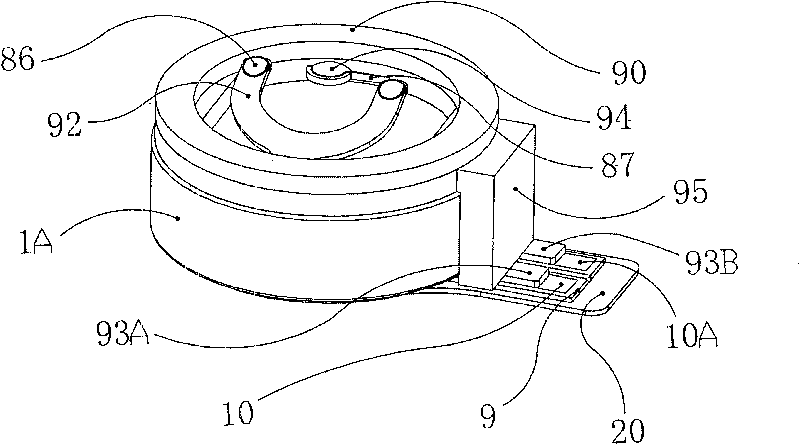

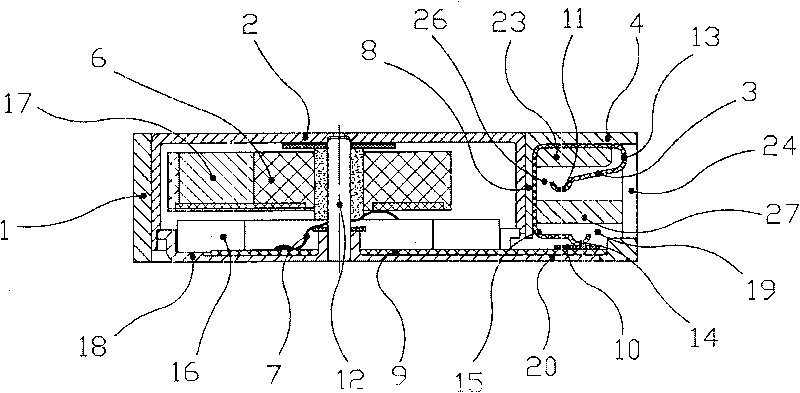

[0031] The electrical connector of the present invention comprises: a flat type vibration source (1A), and the flat type vibration source (1A) is an entity whose height is smaller than the diameter. Such as image 3 As shown, it also includes: a ring-shaped base (1); a base (4) connected to the ring-shaped base (1); and positive metal shrapnel (3) and negative metal shrapnel (3A).

[0032] Since the ring-shaped base (1) and the base (4) are integral in structure, they can be integrally formed by injection molding.

[0033] Figure 4 It is a top view of the flat vibration source of the present invention; as can be seen from the accompanying drawings, the annular base (1) is ring-shaped, and its height is slightly higher or lower than the height of the flat vibration source (1A). The inner wall completely overlaps...

Embodiment 2

[0045] The rest of this embodiment is basically the same as Embodiment 1, except that one of the circuits of the flat type vibration source (1A) is extremely the casing itself, and the other is extremely metal shrapnel or wires. Because the flat type vibration source The upper casing (2) or the lower casing (18) of (1A) can be metal conductors, and a metal conductor (not shown) can be pre-designed on the mobile phone at the position where the flat vibration source (1A) is installed , when the flat type vibration source (1A) is installed on the designated position, the metal conductor is in contact with the upper casing (2) or the lower casing (18) of the flat type vibration source (1A), thereby establishing a Electrical connection. The advantage of this connection method is: because the contact area of the shell of the flat type vibration source (1A) is relatively large, the production requirements for metal conductors can be reduced; because only one metal shrapnel is instal...

Embodiment 3

[0047] The rest of this embodiment is basically the same as Embodiment 1 and Embodiment 2, except that the upper casing (2) and the base (4) are integrally formed by injection molding, and the corresponding annular base is omitted (1). This structure has more obvious advantages than Embodiment 1 and Embodiment 2: Owing to omitting the annular base (1), the profile of the flat type vibration source (1A) electrical connector is smaller and has more space , thus having more competitive advantages. The above casing (2) and the base (4) can be integrated not only by injection molding, but also by other methods such as: welding, riveting, riveting, stretching and the like. Such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com