Input under-voltage/over-voltage protection circuit

An overvoltage protection circuit, input undervoltage technology, applied in the protection of undervoltage or no voltage reaction, the protection of overvoltage reaction, etc., can solve the problem of program confusion, damage to DSP or CPU chips, and output timing confusion and other issues to achieve the effect of preventing program confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

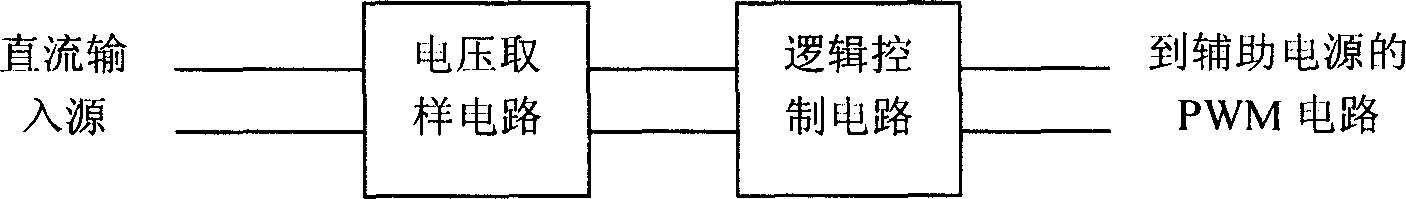

[0039] Such as Figure 4 As shown, a novel input undervoltage / overvoltage protection circuit of the present invention includes a voltage sampling circuit 1 , a logic control circuit 2 , a hysteresis control circuit 3 and a sampling output holding circuit 4 .

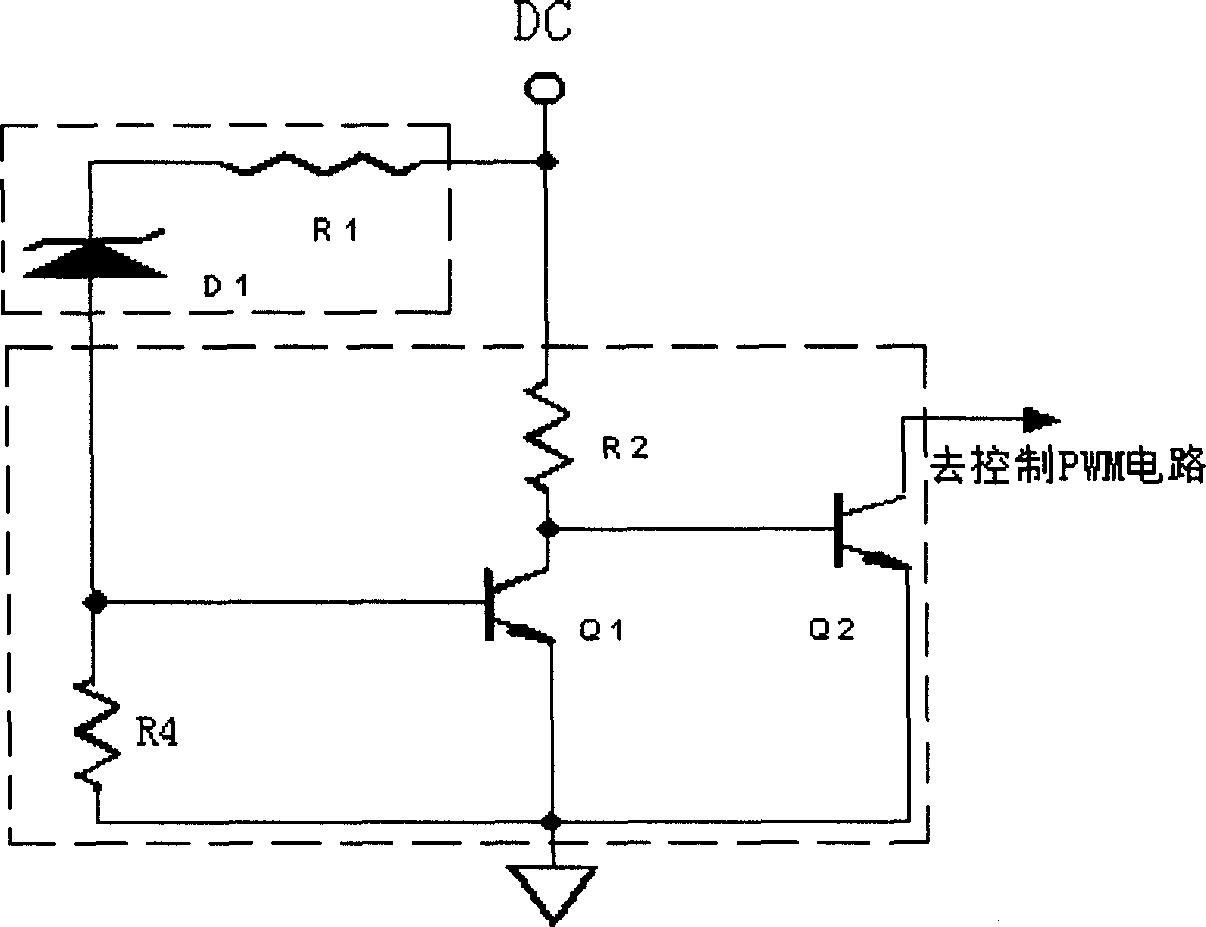

[0040] Such as Figure 7 As shown, the voltage sampling circuit 1 is a series branch composed of a first resistor R1 and a first Zener diode D1. One end of the first resistor R1 is connected to the direct current input source DC, and the other end is connected to the cathode of the first zener diode D1. The other end of the first Zener diode D1 is used as the output end of the voltage sampling circuit 1 . The logic control circuit 2 includes a second resistor R2, a third resistor R3, a fourth resistor R4, a first switch Q1 and a second switch Q2. One end of the second resistor R2 is connected to one end of the third resistor R3 and then connected to the direct current input source DC. One end of the fourth resistor R...

Embodiment 2

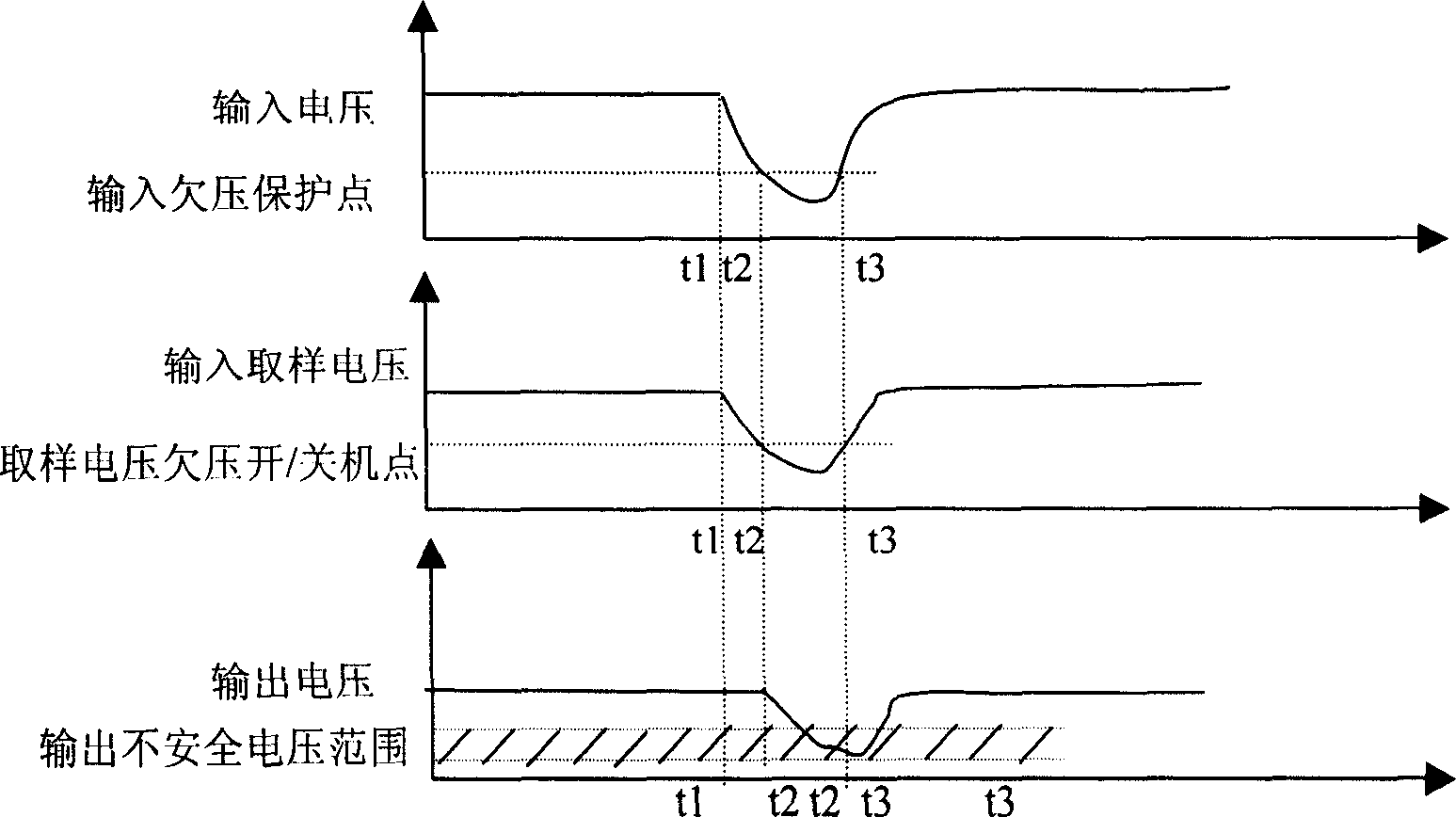

[0047] Such as Figure 10 As shown, compared with the first embodiment, only the sample output hold circuit 4 is removed in this embodiment. Among them, the working principle of hysteresis control circuit 3 is (taking undervoltage protection as an example): when the input voltage is low (below the input undervoltage point), the first voltage regulator diode D1 and the second voltage regulator diode D2 are not conducting , the first switching tube Q1 is turned off, Q2 is turned on, the PWM control pin is pulled down, the PWM has no output, and it is in an undervoltage protection state. The collector voltage of the Q2 tube is low, the Q3 tube is not conducting, and the regulator tube D2 is not bypassed. When the input voltage is greater than the regulated voltage of the regulator tubes D1 and D2 plus the sum of the conduction voltage drop of the base of the Q1 tube V D1 +V D2 +V beQ1 At this time, the Q1 tube is turned on, the Q2 tube is turned off, the Q3 tube is turned on,...

Embodiment 3

[0049] Such as Figure 11 As shown, a new type of input undervoltage / overvoltage protection circuit includes a voltage sampling circuit 1, a logic control circuit 2 and a sampling output holding circuit 4.

[0050] The voltage sampling circuit 1 is a series branch composed of a first resistor R1 and a first Zener diode D1. One end of the first resistor R1 is connected to the direct current input source DC, and the other end is connected to the cathode of the first zener diode D1. The other end of the first Zener diode D1 is used as the output end of the voltage sampling circuit 1 . The logic control circuit 2 includes a second resistor R2, a fourth resistor R4, a first switch Q1 and a second switch Q2. One end of the second resistor R2 is connected to the DC input source. One end of the fourth resistor R4 is connected to the base of the first switching tube Q1 and used as the input end of the logic control circuit 2, coupled with the output end of the voltage sampling circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com