Telescopic ladder for stage loader tail

A telescopic and reloading machine technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that the particle size of the coal block in the rear conveyor cannot be guaranteed, the fixed ladder is not practical, and the ladder is damaged. Simple and reliable, prevent equipment parking, and enhance the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

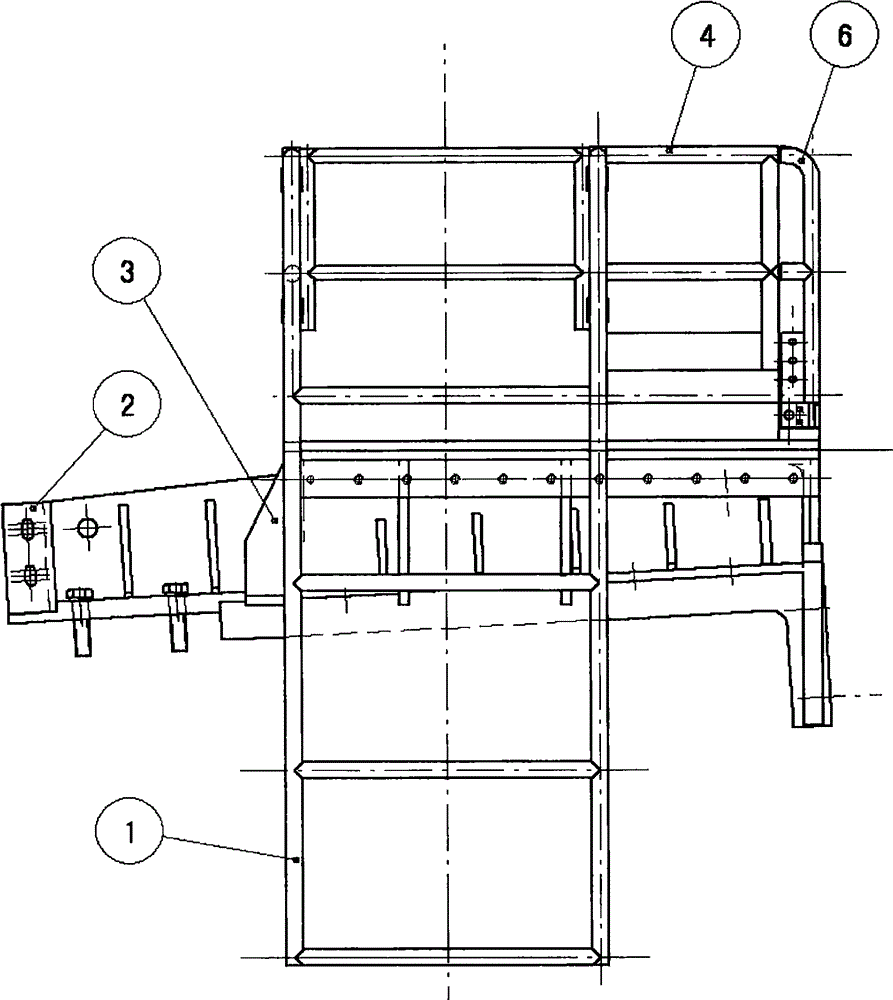

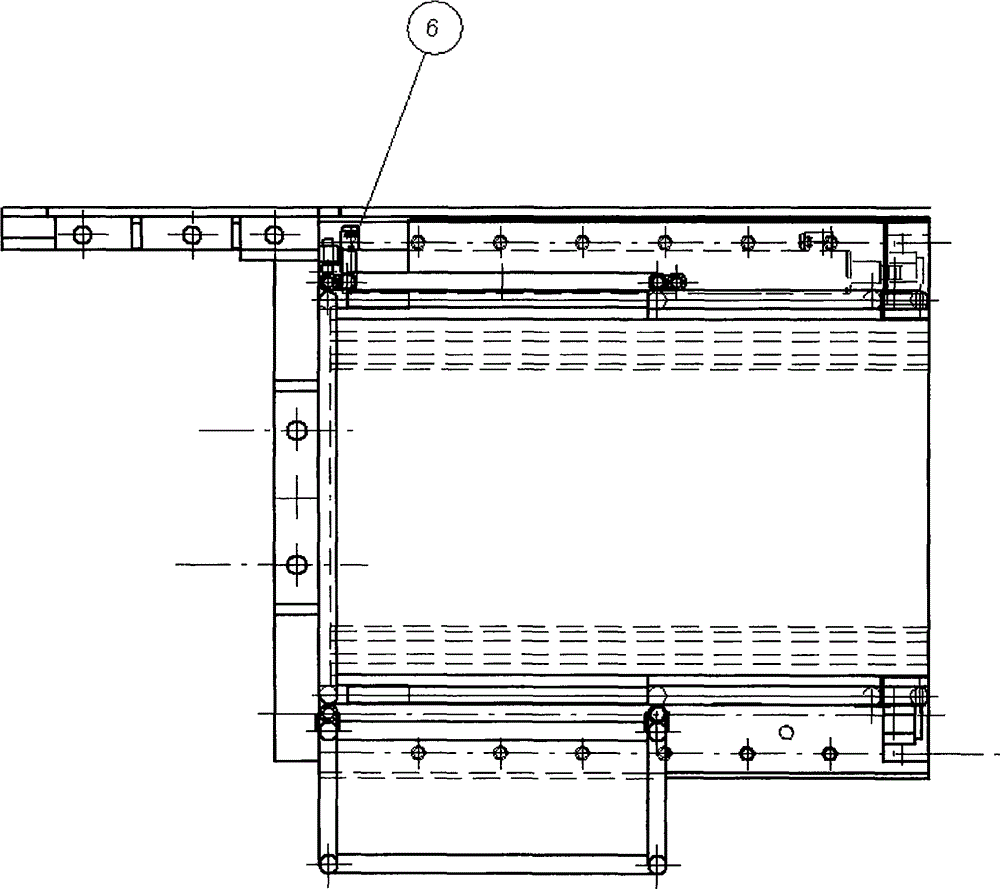

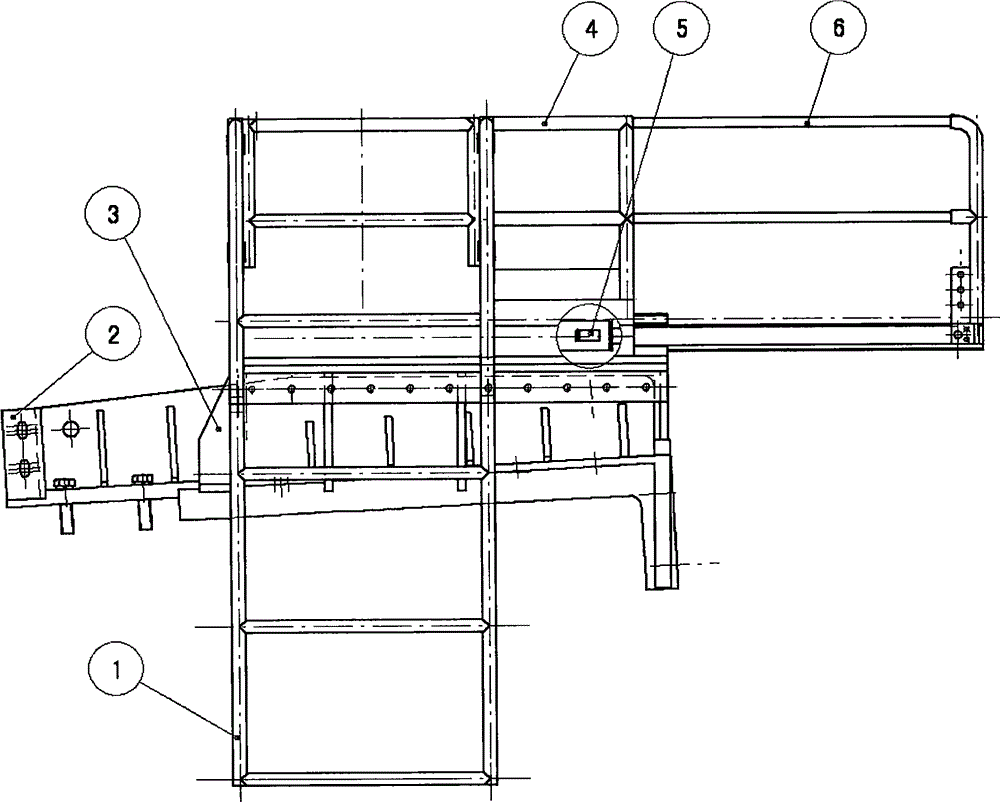

[0011] Such as figure 1 , figure 2 Shown full-enclosed reloading machine tail is with retractable people's ladder, comprises main structures such as people's ladder 1, support 2, support 3, fixed frame 4, oil cylinder 5, slide frame 6.

[0012] image 3 Shown is a schematic diagram of the state of the carriage extended after oil is supplied to the oil cylinder. At this time, the oil cylinder is extended by operating the valve group to extend the oil cylinder, which drives the carriage to extend across the loader and allow the staff to pass. After the worker passes through, operate the control valve to retract the oil cylinder and drive the carriage to retract.

[0013] Figure 4 Shown is a traditional ladder structure, one end is fixed to the baffle side of the unloading section of the reloader, and the other side has no support, and it freely crosses the coal flow of the reloader to connect the two sides. The structure is simple and easy to manufacture, but it is poor in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com