Printed circuit board with improved hole

A technology of printed circuit boards and vias, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc. It can solve the problems of reducing circuit speed, prolonging signal rise time, distortion, etc., and achieves the goal of improving characteristic impedance and signal transmission quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

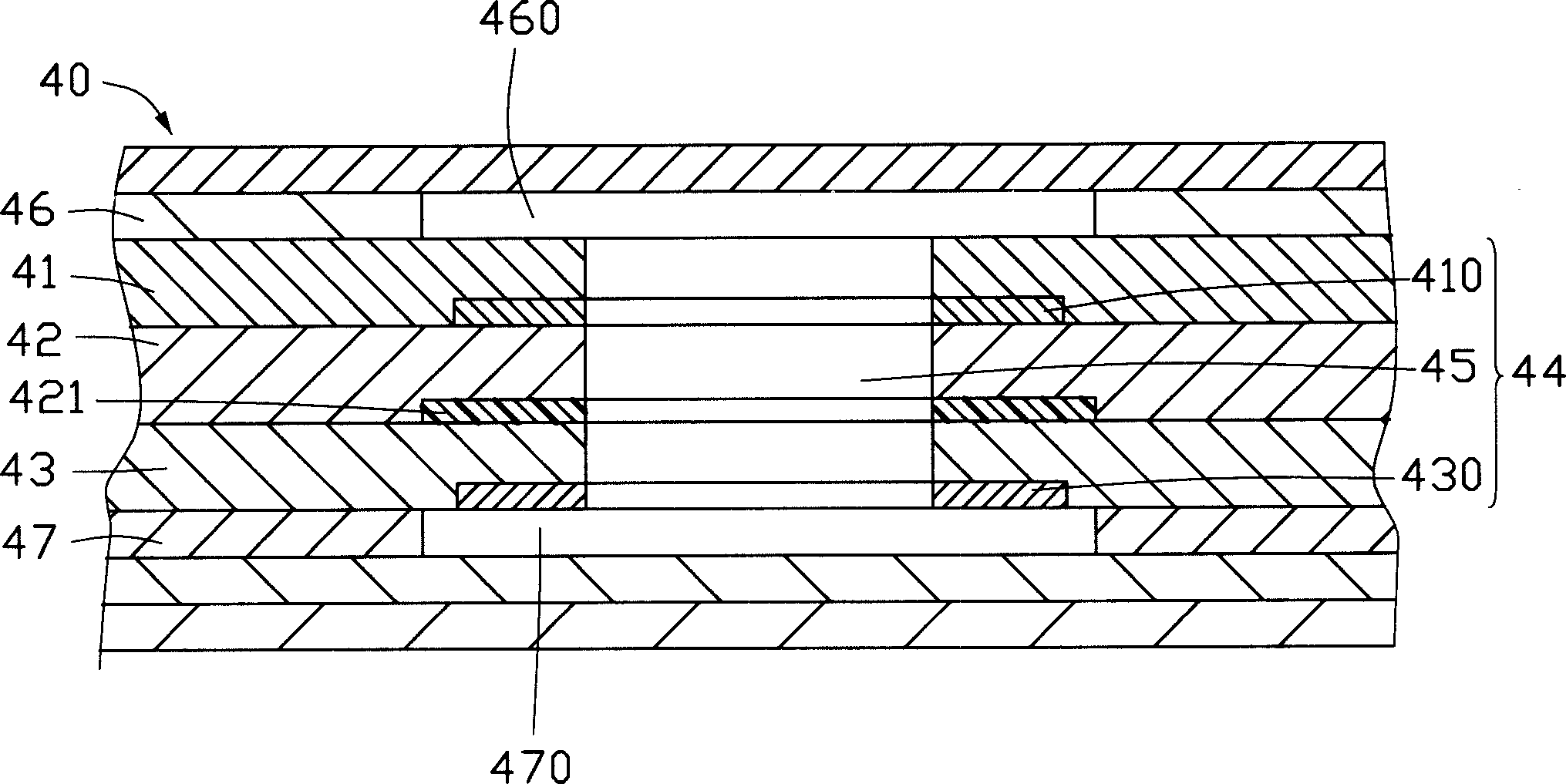

[0015] Please refer to figure 2 , which is a cross-sectional view of a printed circuit board with improved vias in the first preferred embodiment of the present invention, the printed circuit board 40 is an eight-layer board, which includes a first plane layer 41 and a second plane layer 43 , a third planar layer 47, a fourth planar layer 42, a fifth planar layer 46 and a buried hole 44, the buried hole 44 includes a drilled hole 45, a first pad 410 and a second pad 430, the diameter of the first pad 410 is the same as that of the second pad 430, the first pad 410 is located on the first planar layer 41, and the second pad 430 is located on the On the second plane layer 43, the first plane layer 41 and the second plane layer 43 are signal layers, and the first pad 410 and the second pad 430 are used for the drilling 45 and the first plane layer. The connection of traces on the layer 41 and the second plane layer 43 . The drill hole 45 runs through the first plane layer 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com