Branch line directional coupler, design method thereof, and electronic equipment

A technology of directional couplers and branch lines, which is applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of machining accuracy limitation, application limitation, and circuit complexity increase, and achieve large working bandwidth, simple design method, and high efficiency. Effect of characteristic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

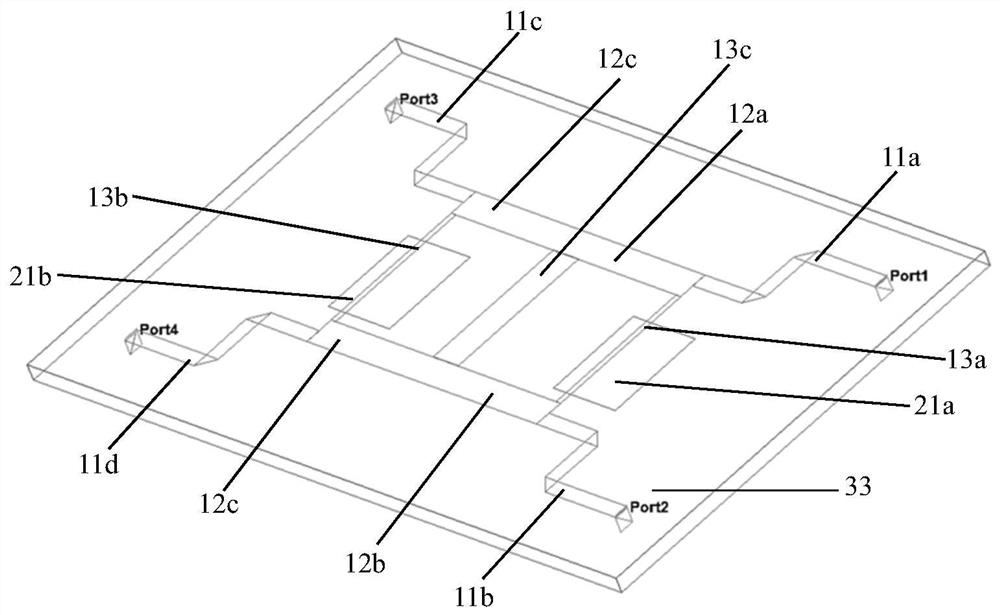

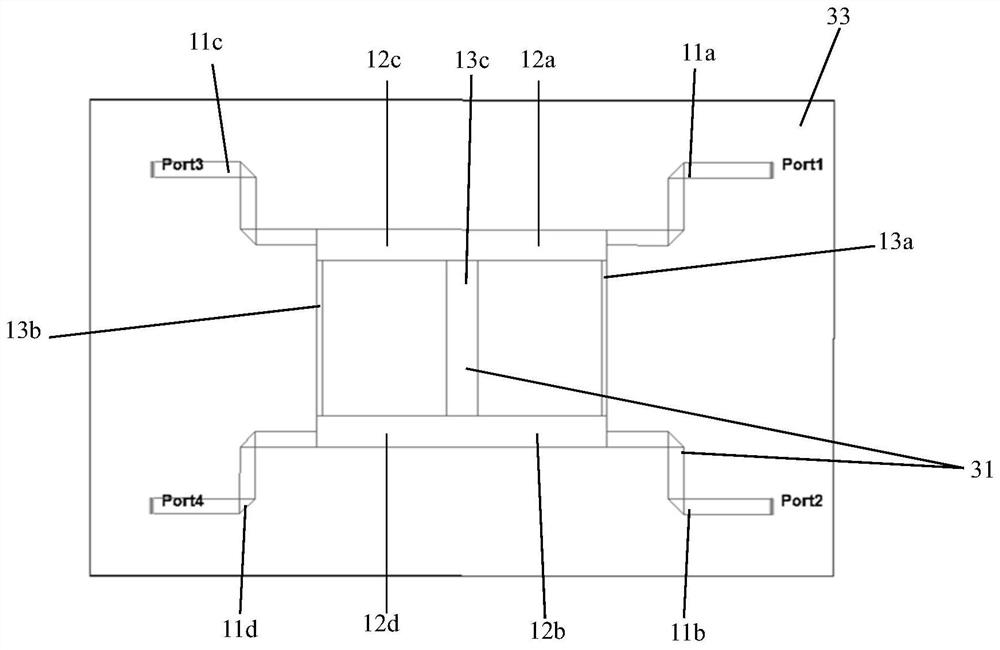

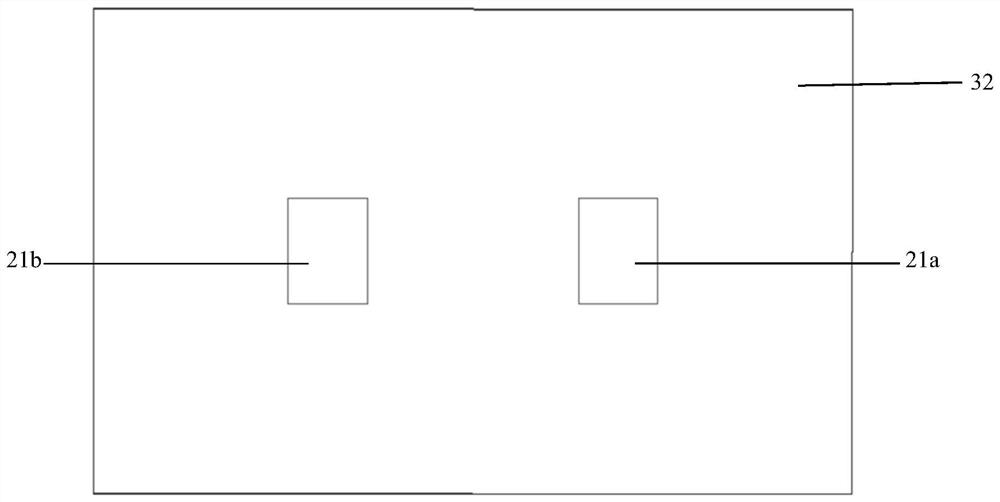

[0050] The essence of the technical solutions of the embodiments of the present application will be explained in detail below in conjunction with the accompanying drawings.

[0051]The embodiment of the present application aims at the high impedance requirement of the branch line of the directional coupler, and utilizes the high impedance characteristics of the defect ground structure to design a load defect ground structure for the high impedance branch line part, and further improve its performance under the premise that a wider transmission line can be realized in actual processing. The characteristic impedance is to meet the design requirements of the principle impedance. At the same time, the physical size of the transmission line can be shortened by utilizing the slow wave effect generated by the structural transmission line loaded with defects, which is beneficial to the miniaturization design of the circuit. The design process of the directional coupler in the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com