Assistant measurement unit for moment wrench in narrow operation area

A technology for auxiliary measurement and torque wrench, which is applied in wrench, measuring torque/torsion force, wrench and other directions during tightening. It can solve the problems of narrow construction space, unusable torque wrench, difficulty in meeting technical requirements, etc., and achieve the convenience of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

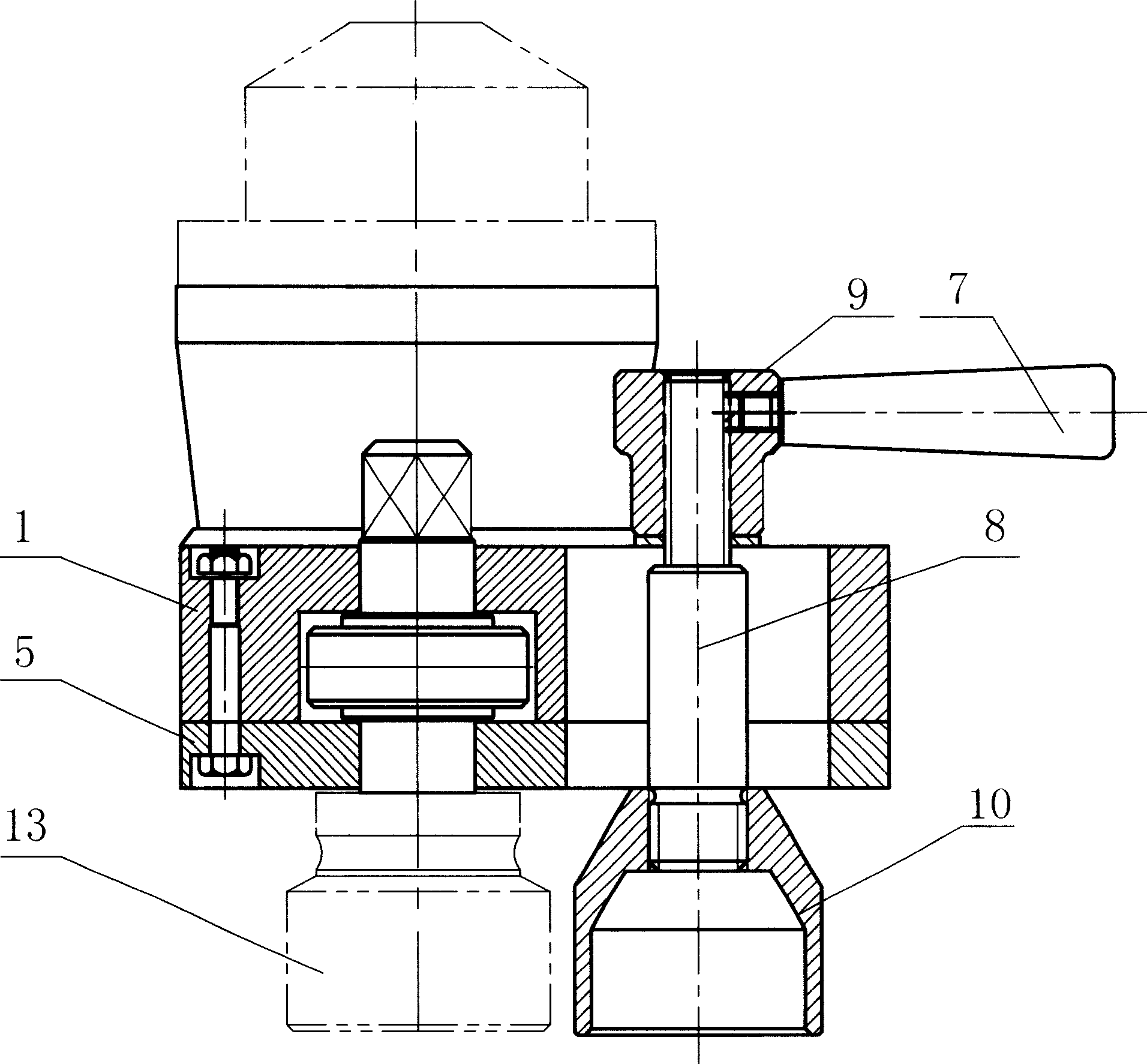

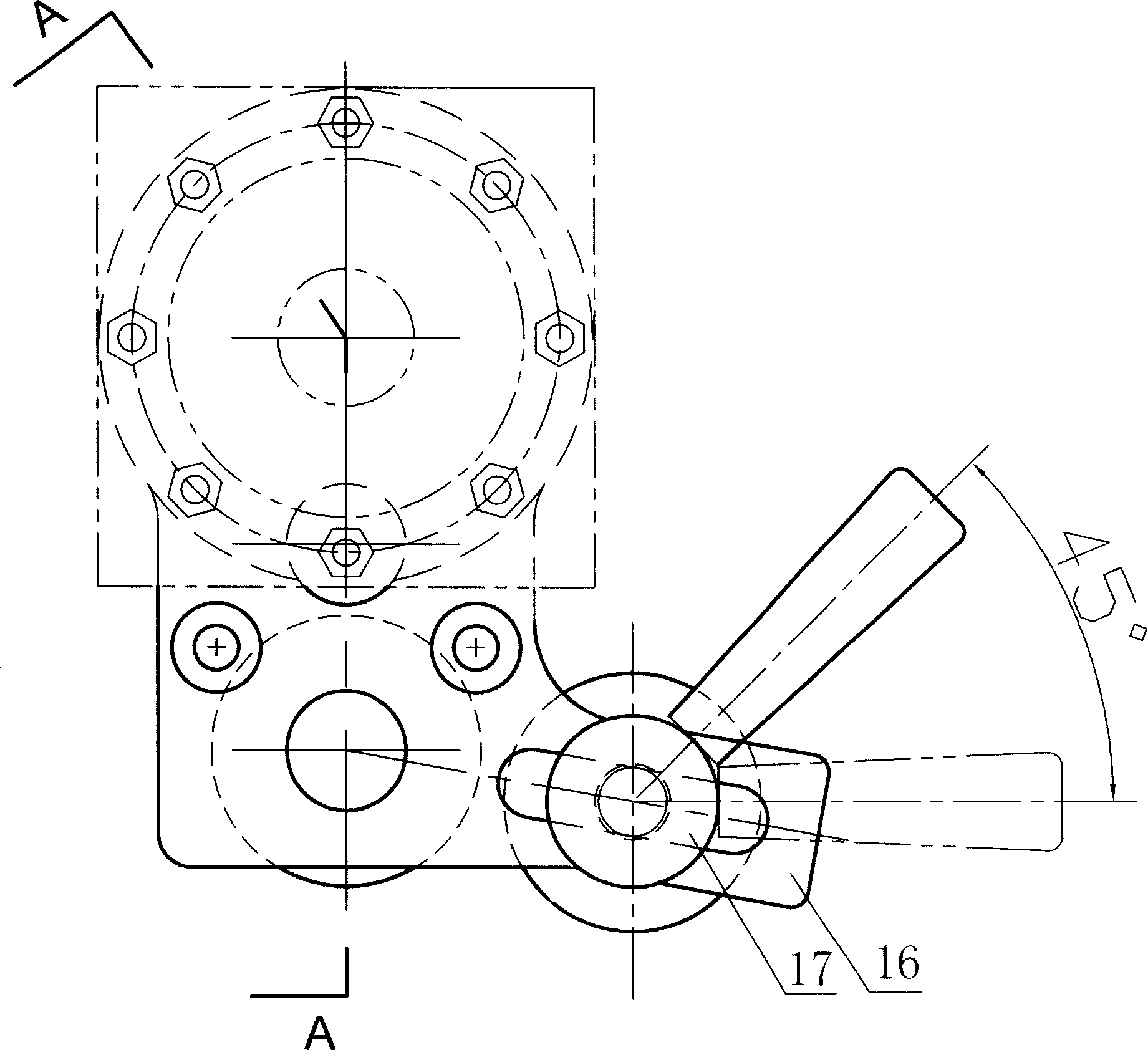

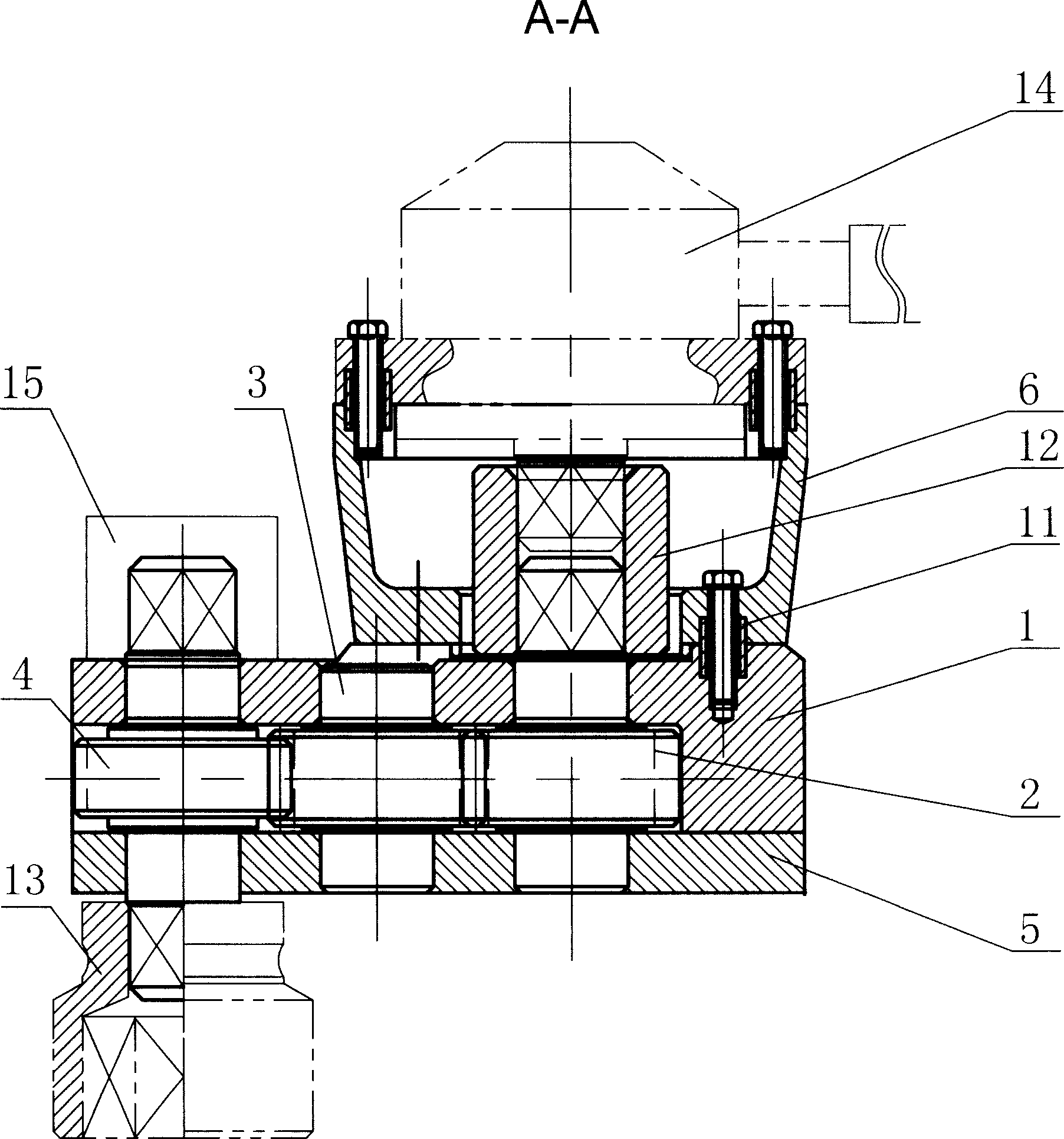

[0011] The torque wrench auxiliary measuring device in a narrow working area includes an electric torque wrench 14, an electric torque wrench control display 15, and a torque transmission device. The torque transmission device includes: an upper cover plate 1, a lower cover plate 5, an input gear 2, an intermediate gear 3, an output gear 4, a connecting housing 6, a shaft sleeve 12, a vertical rod 8, a locking nut 9, The balance sleeve 10, the input gear 2, the intermediate gear 3 and the output gear 4 are all installed between the upper cover plate 1 and the lower cover plate 5, the input gear 2 meshes with the intermediate gear 3, and the intermediate gear 3 meshes with the output gear 4. The upper cover 1 is assembled and fixedly connected with the lower cover 5, and the transmission shaft head at the upper end of the input gear 2 is put into the coupling sleeve 12, and the coupling sleeve 12 is installed in the middle of the connection housing 6, and the connection housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com