Method for producing xylobiose, and dedicated immobilized enzyme

A technology for immobilizing enzymes and xylanases, applied in directions such as hydrolase, bacteria, etc., which are immobilized on/in organic carriers, can solve the problems of low proportion of xylobiose, and achieve easy control of product composition, The effect of high recovery of enzyme activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

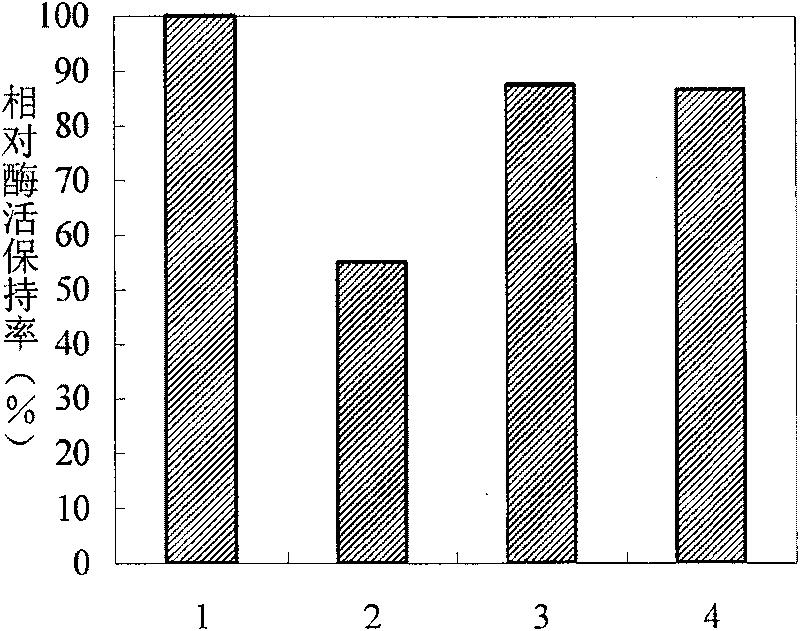

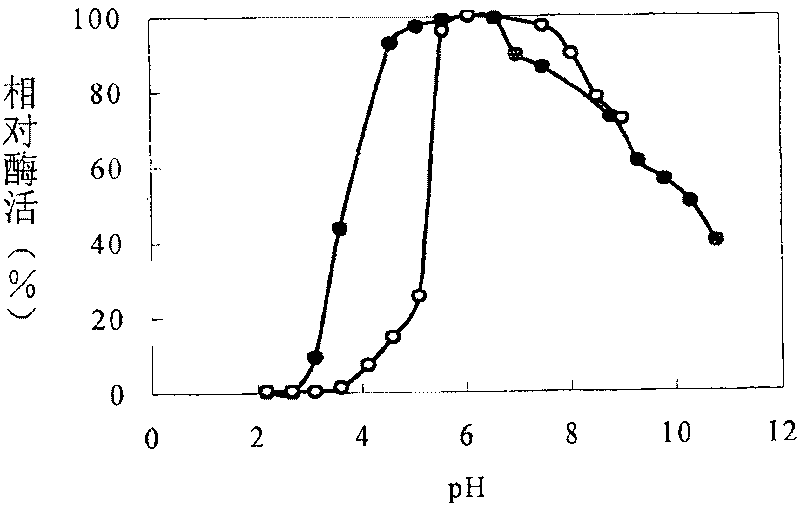

[0041] Embodiment 1, preparation immobilized xylanase

[0042] 1. Preparation of Eupergit C 250L-Ni immobilized XynB

[0043] 1. Preparation of XynB enzyme solution

[0044] The crude enzyme solution was obtained according to the method described in the first paragraph of Example 2, Example 3, Example 4, and Example 5 of Chinese Patent ZL 02156022.6. The specific method is as follows:

[0045] (1) Amplification of xylanase gene xynB

[0046] The primers used are TM-XynB-Nco I-FWD and TM-XynB-Hind-His-REV, and their sequences are as follows:

[0047] TM-XynB-Nco I-FWD: 5'-CCATGGAAA TATTACCTTC TGTGTGAT (SEQ ID NO: 2)

[0048] TM-XynB-Hind-His-REV: 5'-AAGCTTT CTTTCTTCTA TCTTTTTCTC CA (SEQ ID NO: 3)

[0049] According to the complete sequence of the xynB gene of Thermotoga maritima MSB8 DSM3109 preserved in the German Microorganism Collection (DSM), the above-mentioned pair of primers were designed, and the pET28a (+) (Novagen, USA) plasmid capable of inserting into the prime...

Embodiment 2

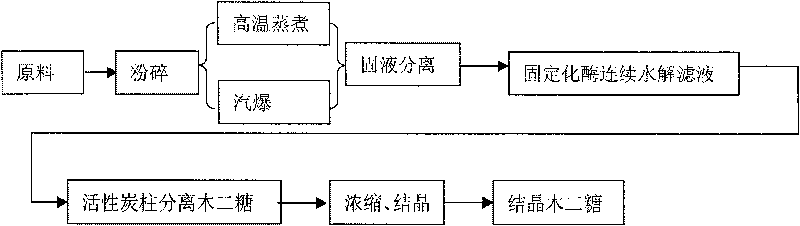

[0087] Embodiment 2, the preparation of steam explosion liquid or high temperature cooking liquid

[0088] 1. Preparation of corn cob steam explosion liquid or high temperature cooking liquid

[0089] 1. Preparation of steam explosion liquid

[0090] Weigh 100g corn cob (containing 32.4% xylan), add 800mL of distilled water according to the solid-to-liquid ratio of 1:8, soak at room temperature for 12h, put it into a high-pressure tank, cover and seal, heat, and keep the temperature at 165-170°C for 30min Immediately after opening the ball valve, the material is released into the collection tank. When the temperature of the collected material drops to 60-70°C, it is sucked and filtered, and the filtrate is the steam explosion liquid. After cooling to room temperature, determine its total sugar and reducing sugar content. Among them, the content of reducing sugar was determined by Somogyi method with D-xylose as the standard. The total sugar was determined by the Orcinol-HC...

Embodiment 3

[0095] Embodiment 3, using the immobilized xylanase of embodiment 1 to continuously hydrolyze the steam explosion liquid or high-temperature cooking liquid of embodiment 2

[0096] 1. Hydrolysis of Eupergit C 250L-Ni immobilized XynB column treated with 1M phosphate buffer Example 2 Corn cob steam explosion liquid or high temperature cooking liquid

[0097] The experiment set up 3 repetitions. Each repetition added 40g wet state (prepared by 10g Eupergit C 250L) 1M phosphate buffered Eupergit C 250L-Ni immobilized XynB to a stainless steel jacketed chromatography column with an internal diameter of 15mm, the actual height of the enzyme bed was 33cm, and the connection constant flow pump and fraction collector ( Figure 5 ), equilibrate with 50mM, pH 6.2 citric acid buffer for 30min. The substrate is corncob steam-popping liquid or high-temperature cooking liquid, wherein the total sugar content of corncob steam-popping liquid is 22.0mg / mL, and the reducing sugar content is 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com