Electronical expansion valve in use for refrigeration system

An electronic expansion valve, refrigeration system technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of reducing valve stability and reliability, increasing processing difficulty and cost, increasing expansion valve leakage, etc. The effect of improving reliability, simple structure and stable friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

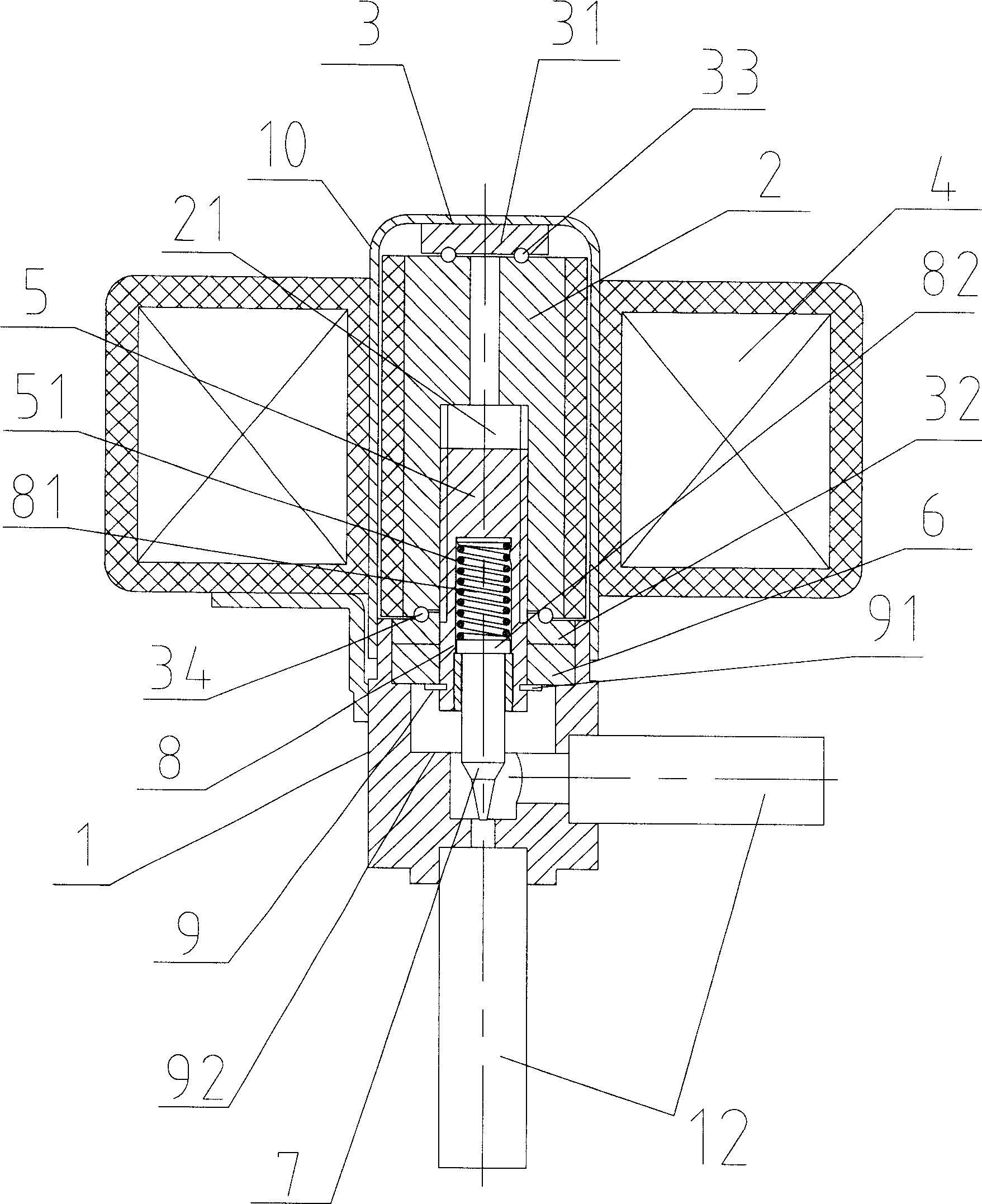

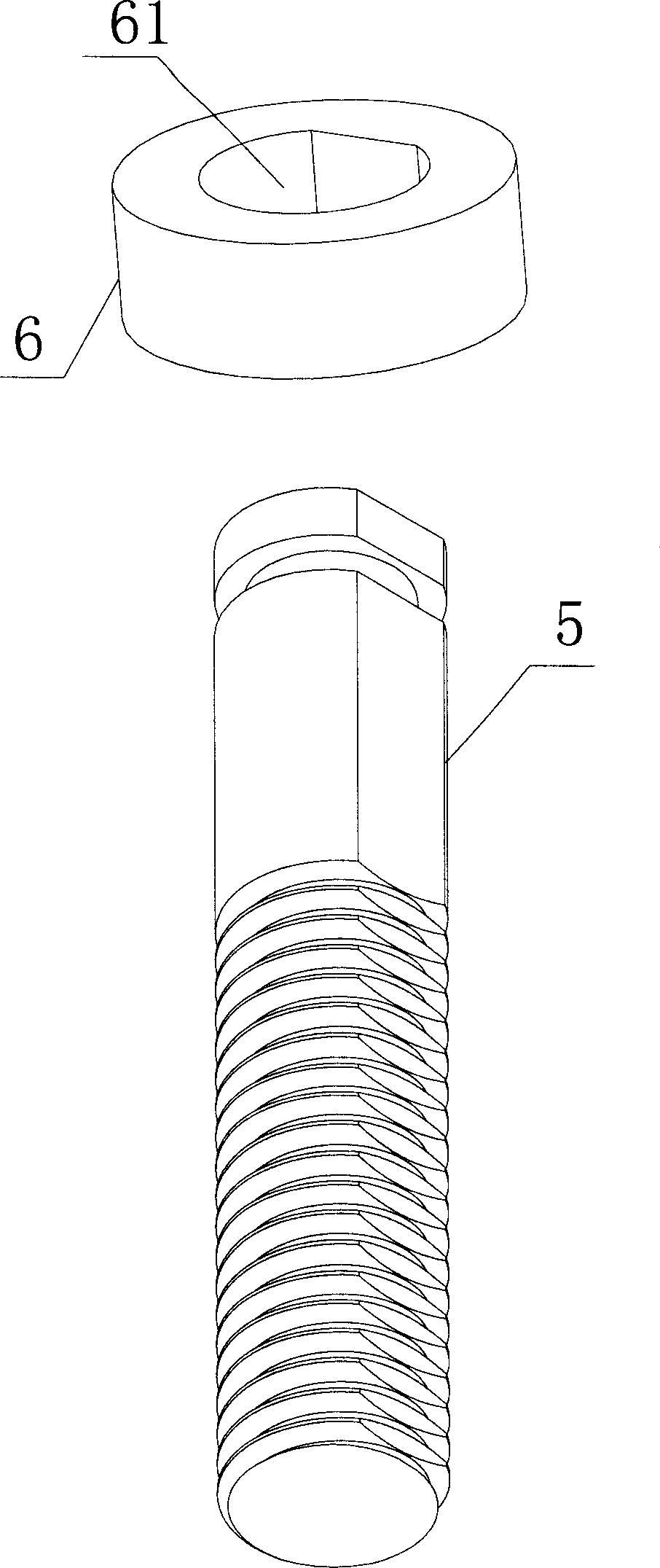

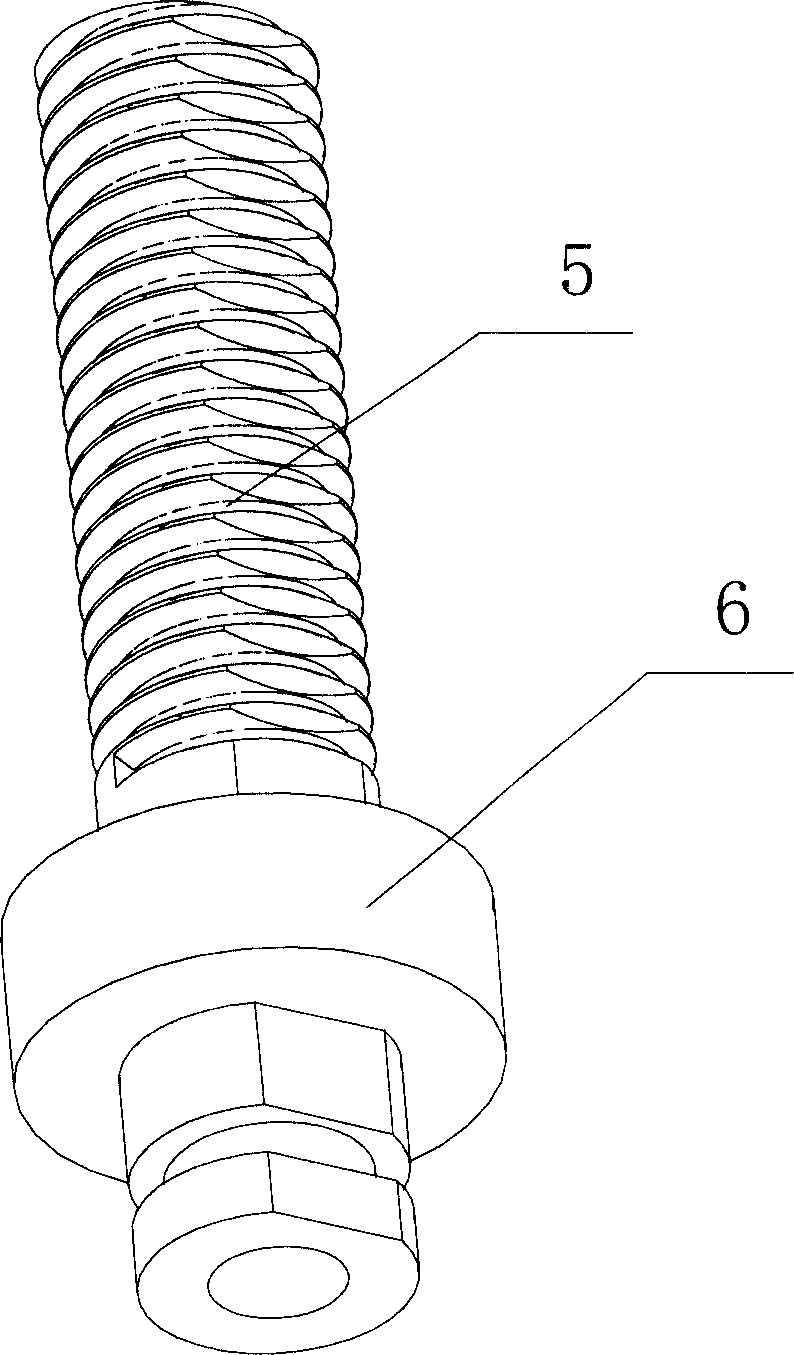

[0044] Embodiment one, such as Figures 1 to 3 As shown, an electronic expansion valve used in a refrigeration system includes a valve body 1, a rotor 2, a positioning device 3, a coil 4, a mandrel screw 5, an anti-rotation part 6, a valve needle 7, an adjustment device 8, and a limit device 9. A sealing sleeve 10, a coil positioning bracket 11 and an inlet and outlet connecting pipe 12.

[0045] Among them, the sealing sleeve 10 is sleeved and welded on the valve body 1; the coil fixing frame 11 is fixed on the valve body 1; the coil 4 is set outside the sealing sleeve 10 and fixed on the coil fixing frame 11; the valve body 1 corresponds to the coil The rotor 2 is installed at 4 places; the positioning device 3 includes upper and lower bearing supports 31, 32 and upper and lower bearing supports 33, 34, the upper and lower bearing supports 31, 32 are respectively fixed in the valve body 1, and the upper bearing supports 33 Installed in the upper bearing support block 31 an...

Embodiment 2

[0048] Embodiment two, such as Figure 4 As shown, an electronic expansion valve used in a refrigeration system is different from Embodiment 1 in that only the lower bearing-type support 32 and the lower bearing-type support 34 are used to realize the positioning device 3, and the upper bearing-type support is not required. 31 and the upper bearing support 33, the lower bearing support 32 is fixed in the valve body 1, the lower bearing support 34 is installed in the lower bearing support 32, and cooperates with the lower end of the rotor 2, the lower bearing support 34 is Rolling bearing type support. work process:

[0049] The coil 4 is connected with direct current according to a certain phase sequence, and a rotating magnetic field is generated around the coil 4; the rotor 2 is affected by the rotating magnetic field, and under the limitation of the upper bearing support 33, it cannot perform lifting motion, but only rotates; the rotor 2 The rotation is transmitted to the...

Embodiment 3

[0052] Embodiment three, such as Figure 5 As shown, the difference from Embodiment 1 is that one end of the mandrel screw 5 is placed in the cavity at the lower part of the valve body 1, and is threadedly fitted with the valve body 1; the anti-rotation part 6 is fixed in the rotor 2 to prevent The rotating part 6 can be fixed in the rotor 2 through interference fit or welding, and the other end of the mandrel screw 5 is installed in the anti-rotation part 6, and the rotor 2 drives the mandrel screw 5 to rotate and lift through the anti-rotation part 6 The limiting device 9 is set in the valve body 1 to limit the range of the mandrel screw 5 for lifting movement; the upper end of the valve needle 7 is installed in the second cavity 51 at the bottom of the mandrel screw 5 . Correspondingly, the limit device 9 includes an upper limit device 91 and a lower limit device 92. The upper limit device 91 is the top wall of the valve body 1. When the spindle screw 5 moves upward to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com