Waterproof case for in-vehicle camera

A technology for vehicle-mounted cameras and waterproof boxes, which is applied to vehicle parts, televisions, electrical components, etc., can solve problems such as the decline in waterproof performance, and achieve the effect of preventing washing and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

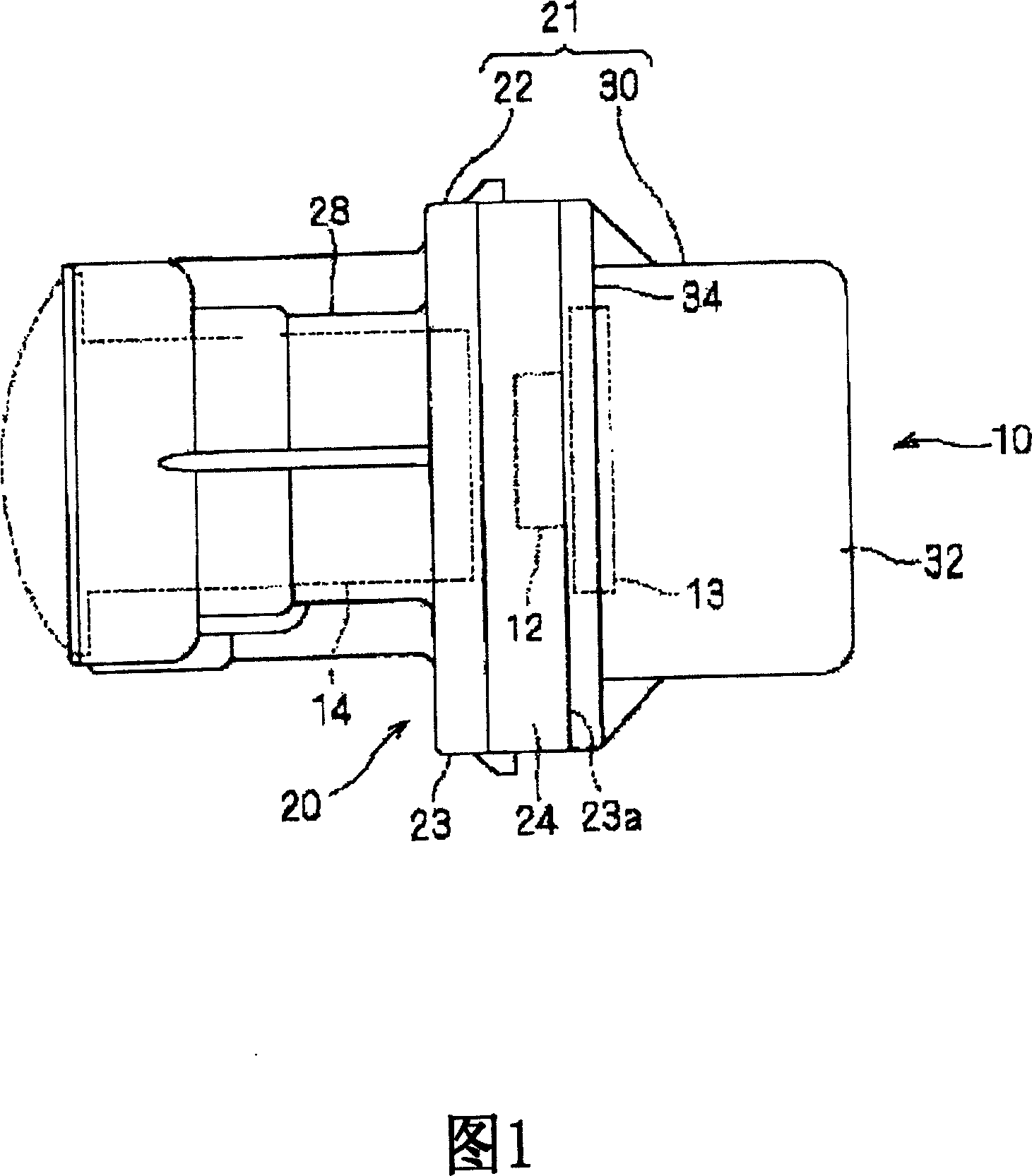

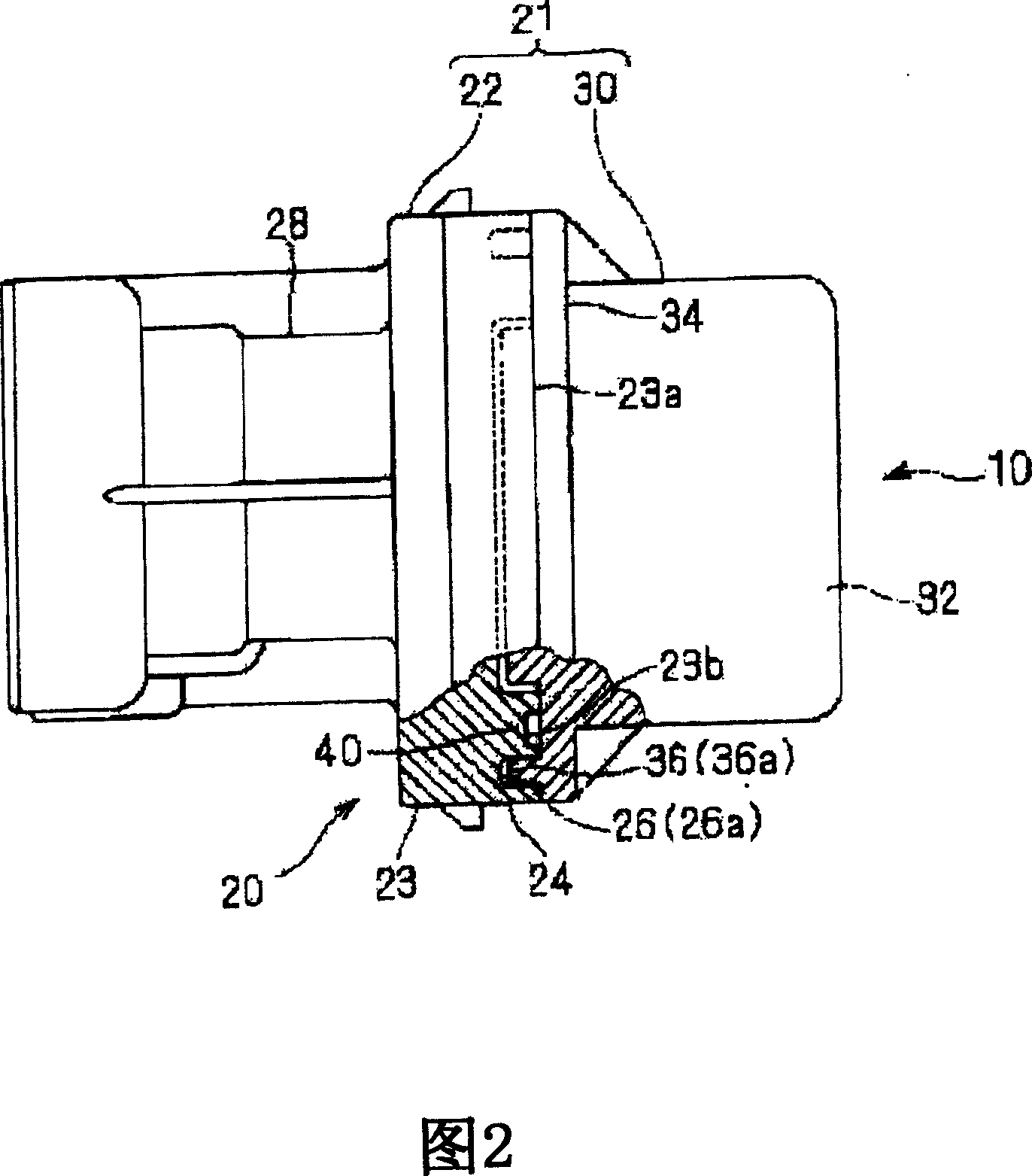

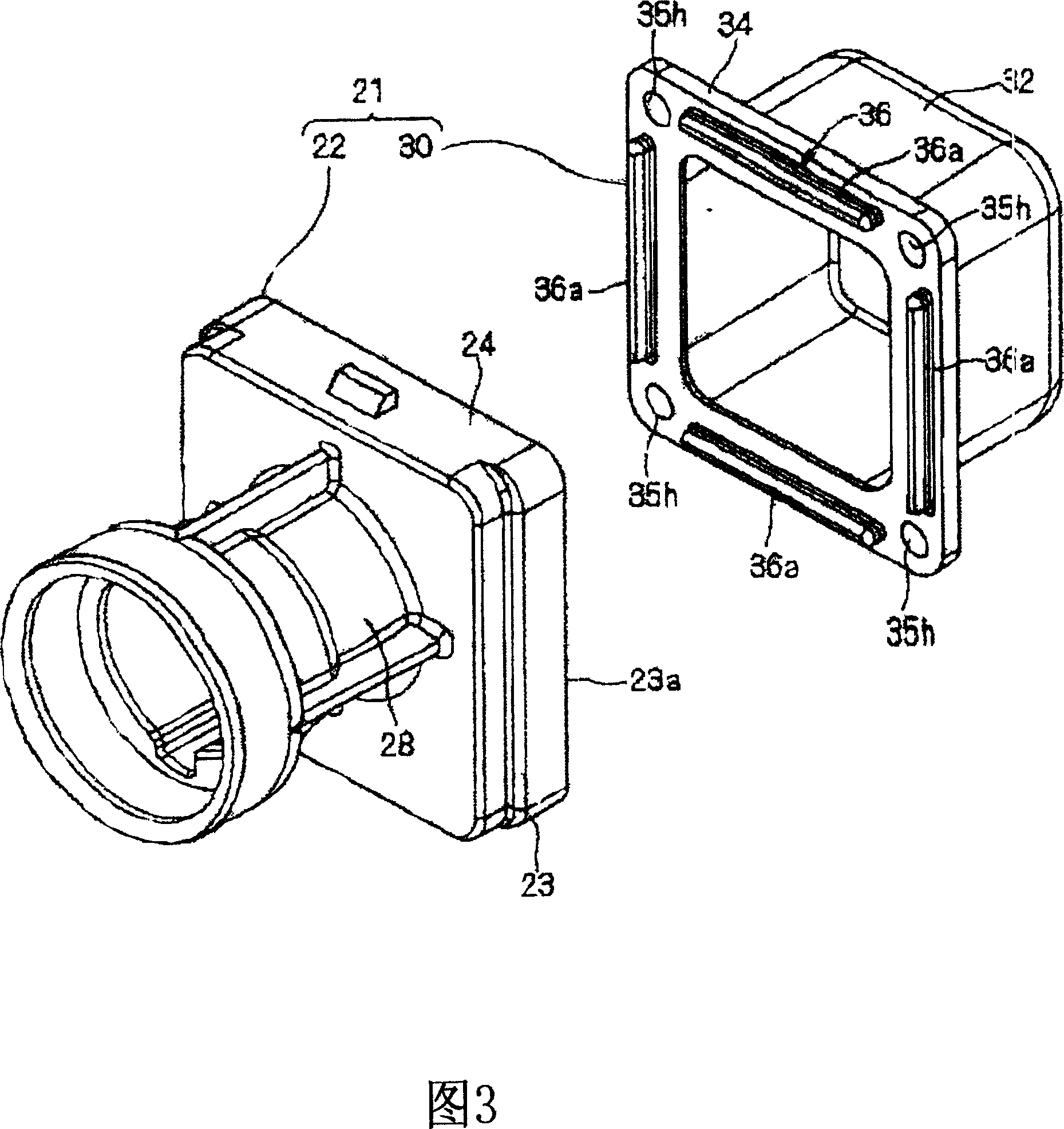

[0024] Next, a waterproof case for a vehicle-mounted camera and a camera device according to an embodiment of the present invention will be described. Fig. 1 is a side view showing a waterproof case for a camera device, Fig. 2 is a partially cut-away sectional view showing the waterproof case, Fig. 3 is an exploded perspective view of the waterproof case seen from the oblique front, and Fig. 4 is a perspective view of the waterproof case viewed from the oblique rear An exploded perspective view of the waterproof case. In addition, for convenience of description, the image side (lens side) is referred to as the front side, and the imaging surface side (imaging element side) is described as the rear side.

[0025] Furthermore, the vehicle-mounted camera 10 to which this waterproof case 20 is applied is installed, for example, outside the vehicle body such as the front, rear, or side of the vehicle. Furthermore, a wide area including the left and right sides of the front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com