Powdered activated carbon dry-method feeding system

A powdered activated carbon and dry process technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve the problems of difficulty in exerting the advantages of powdered activated carbon, low degree of automation control, flying dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

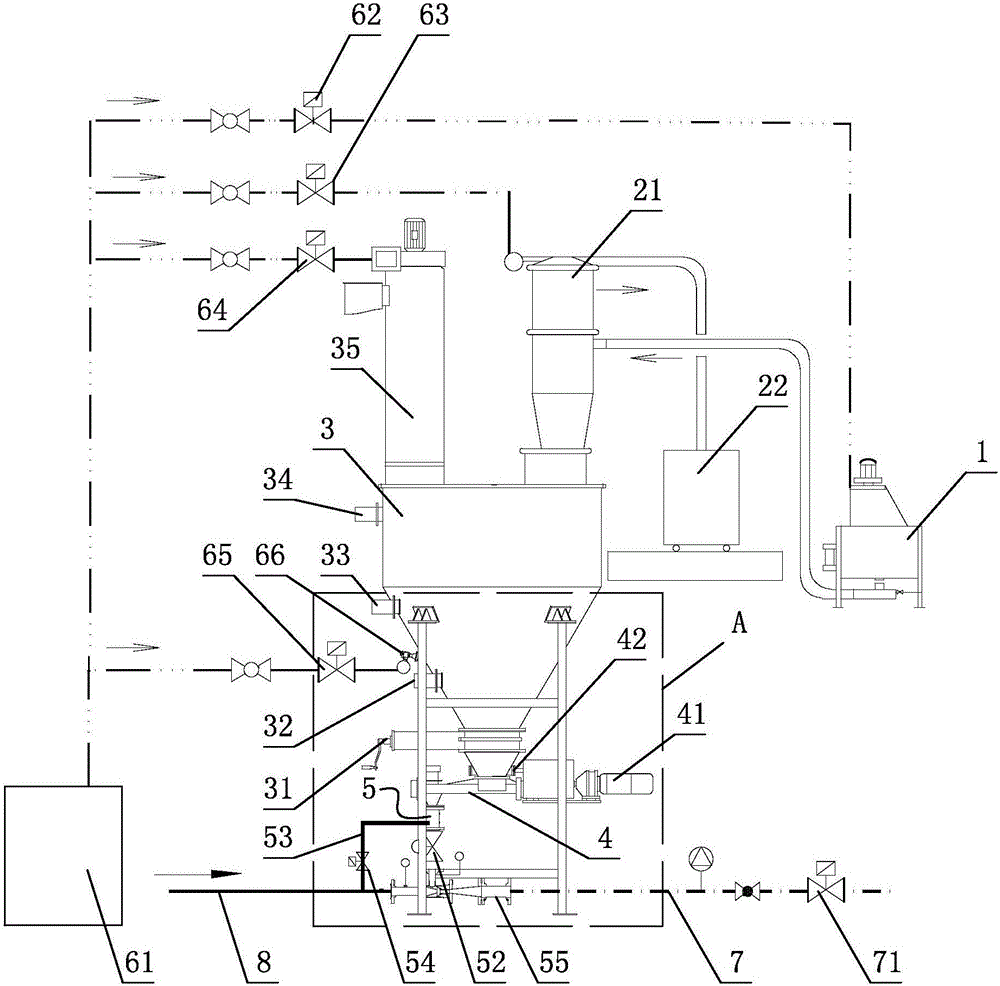

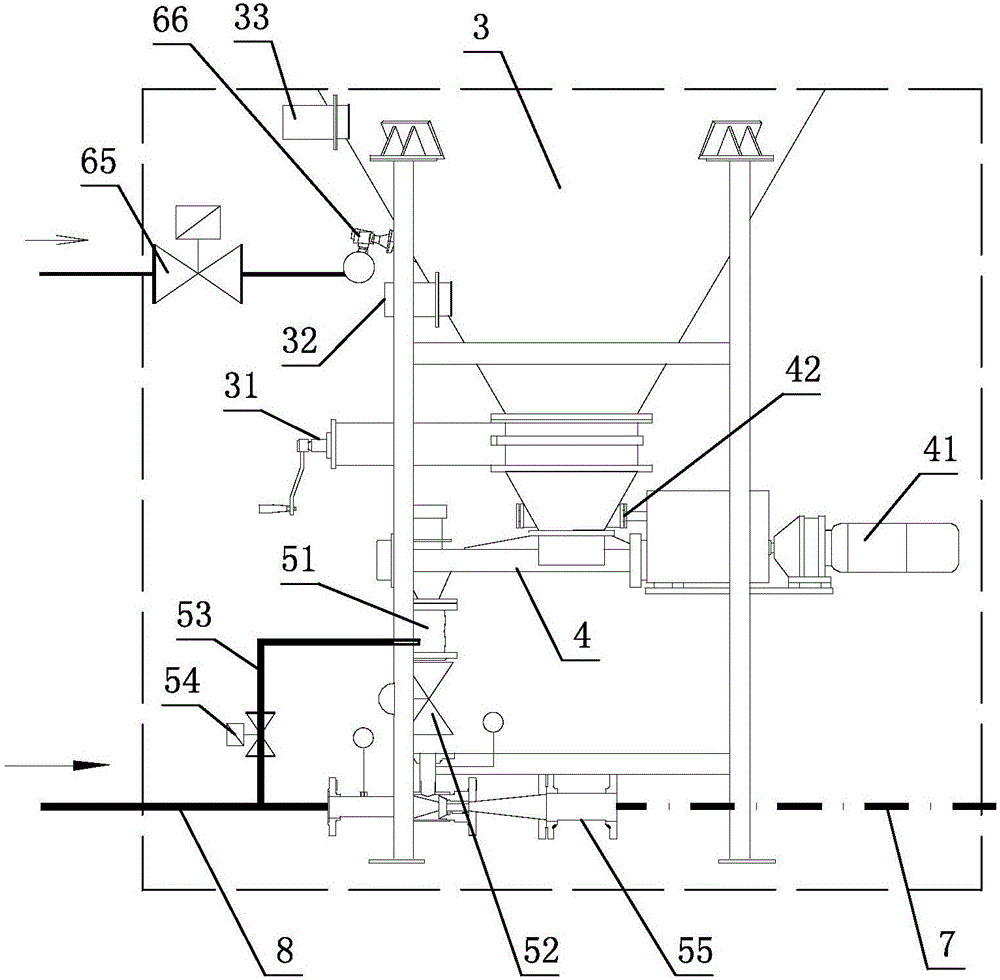

[0023] Embodiment one: if figure 1 with figure 2 As shown, a powdered activated carbon dry dosing system includes a feeding station 1, the feeding station 1 is connected with a feeding mechanism, the bottom of the feeding mechanism is connected with a silo 3, and the upper part of the silo 3 is provided with a top dust collector 35, The lower part of the silo 3 is provided with a discharge valve 31, the lower end of the discharge valve 31 is provided with a discharge mechanism, the discharge end of the discharge mechanism is connected with a blanking mechanism 5, and the lower part of the blanking structure is provided with a water supply pipeline 8 The connected jet mixer 55 is connected with a medicine discharging mechanism. The bagged powdered activated carbon is manually unpacked and poured into the feeding station 1, the feeding mechanism and the top dust collector 35 are started, and the powder in the feeding station 1 is transported to the feeding bin 3. When dosing,...

Embodiment 2

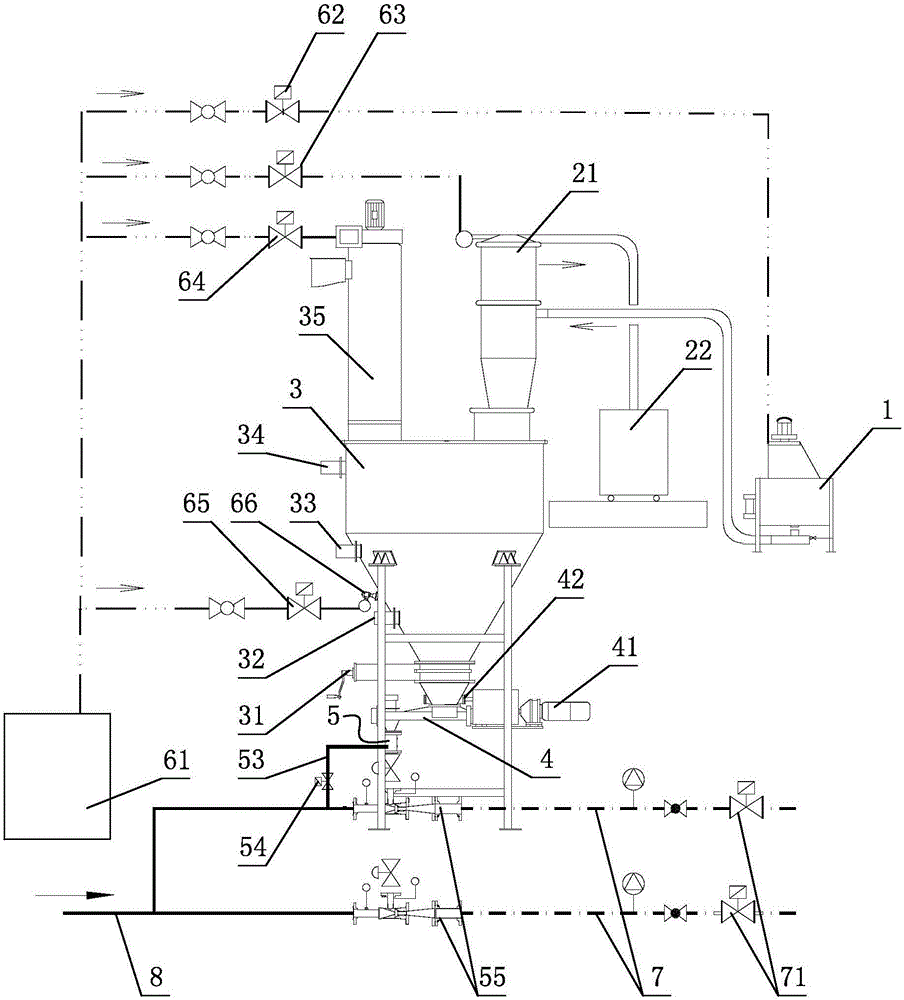

[0036] Embodiment two: if image 3 As shown, the difference between the second embodiment and the first embodiment is that the number of the blanking mechanism 5, the jet mixer 55 and the drug discharge mechanism are respectively two, and the two blanking mechanisms 5 can simultaneously drop materials and transport them separately. To the corresponding jet mixer 55 and the medicine discharge mechanism, realize simultaneous discharge, which greatly improves the work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com