Glass cleaning agent suitable for spray cleaning and preparation method thereof

A technology of glass cleaning agent and chelating agent, which is applied in the direction of detergent compounding agent, chemical instrument and method, detergent composition, etc., which can solve the problems of easy hanging water drops and achieve good low foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

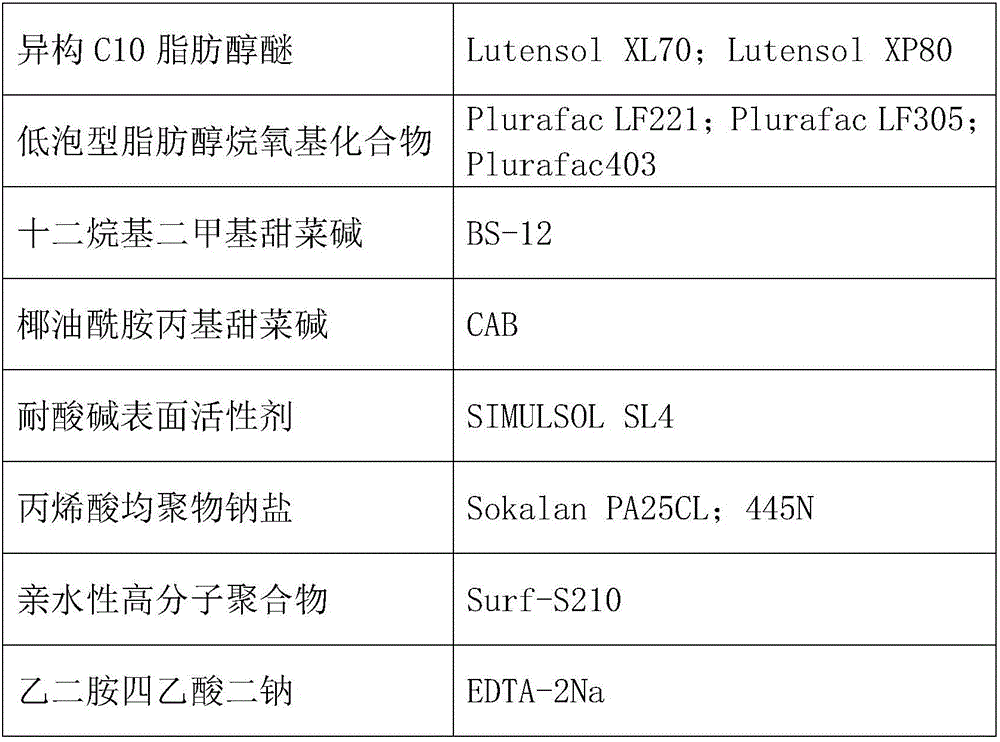

[0031] Example 1: Take 6 parts of isomeric C10 fatty alcohol ether (Lutensol XL70), 3 parts of low-foam fatty alcohol alkoxylate (Plurafac LF221), 0.5 part of dodecyl dimethyl betaine (BS-12) As amphoteric surfactant, 5 parts of acid and alkali resistant surfactant (SIMULSOL SL4) as brightener, 5 parts of acrylic acid homopolymer sodium salt (445N), 10 parts of hydrophilic polymer (Surf-S210) as hardener Surface film-forming agent, 0.5 part of disodium ethylenediaminetetraacetic acid (EDTA-2Na) as chelating agent, 10 parts of isopropanol as solvent, 60 parts of demineralized water, set aside.

[0032] Add demineralized water at 30°C to the container, start the agitator to stir the container, add the chelating agent to the demineralized water and stir until completely dissolved, then add isomeric C10 fatty alcohol ether, low-foaming fatty alcohol alkoxylate and amphoteric surfactant and stirred until completely dissolved to obtain solution a.

[0033] Add the brightener to sol...

Embodiment 2

[0035] Example 2: Take 3 parts of isomeric C10 fatty alcohol ether (Lutensol XL70), 2 parts of low-foam fatty alcohol alkoxylate (Plurafac LF221), 1 part of dodecyl dimethyl betaine (BS-12) As an amphoteric surfactant, 3 parts of acid and alkali resistant surfactant (SIMULSOL SL4) as a brightener, 3 parts of acrylic acid homopolymer sodium salt (445N), 8 parts of a hydrophilic polymer (Surf-S210) as a hardener Surface film-forming agent, 0.5 part of disodium ethylenediaminetetraacetic acid (EDTA-2Na) as chelating agent, 15 parts of ethanol as solvent, 64.5 parts of demineralized water, set aside.

[0036] Add demineralized water at 10°C to the container, start the agitator to stir the container, add the chelating agent to the demineralized water and stir until completely dissolved, then add isomeric C10 fatty alcohol ether, low-foaming fatty alcohol alkoxylate and amphoteric surfactant and stirred until completely dissolved to obtain solution a.

[0037] Add the brightener to...

Embodiment 3

[0039] Example 3: 7 parts of isomeric C10 fatty alcohol ether (Lutensol XL70), 3 parts of low-foaming fatty alcohol alkoxylate (Plurafac LF221), 0.5 part of dodecyl dimethyl betaine (BS-12) as Amphoteric surfactant, acid and alkali resistant surfactant (SIMULSOL SL4) 6 parts as brightener, acrylic acid homopolymer sodium salt (445N) 3 parts, hydrophilic polymer (Surf-S210) 7 parts as hard surface As a film-forming agent, 0.5 parts of disodium ethylenediaminetetraacetic acid (EDTA-2Na) is used as a chelating agent, 15 parts of ethanol is used as a solvent, and 58 parts of demineralized water are set aside.

[0040] Add demineralized water at 40°C to the container, start the agitator to stir the container, add the chelating agent to the demineralized water and stir until completely dissolved, then add isomeric C10 fatty alcohol ether, low-foam fatty alcohol alkoxylate and amphoteric surfactant and stirred until completely dissolved to obtain solution a.

[0041] Add the brighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com