Fabric thin-belt type sound-membrane loudspeaker

A thin-ribbon loudspeaker technology, which is applied in the improvement field of ribbon loudspeakers, can solve the problems of high failure rate, great impact on sound, and low damping of aluminum strip materials, so as to save matching transformers, excellent shape retention ability, Avoid the effect of poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

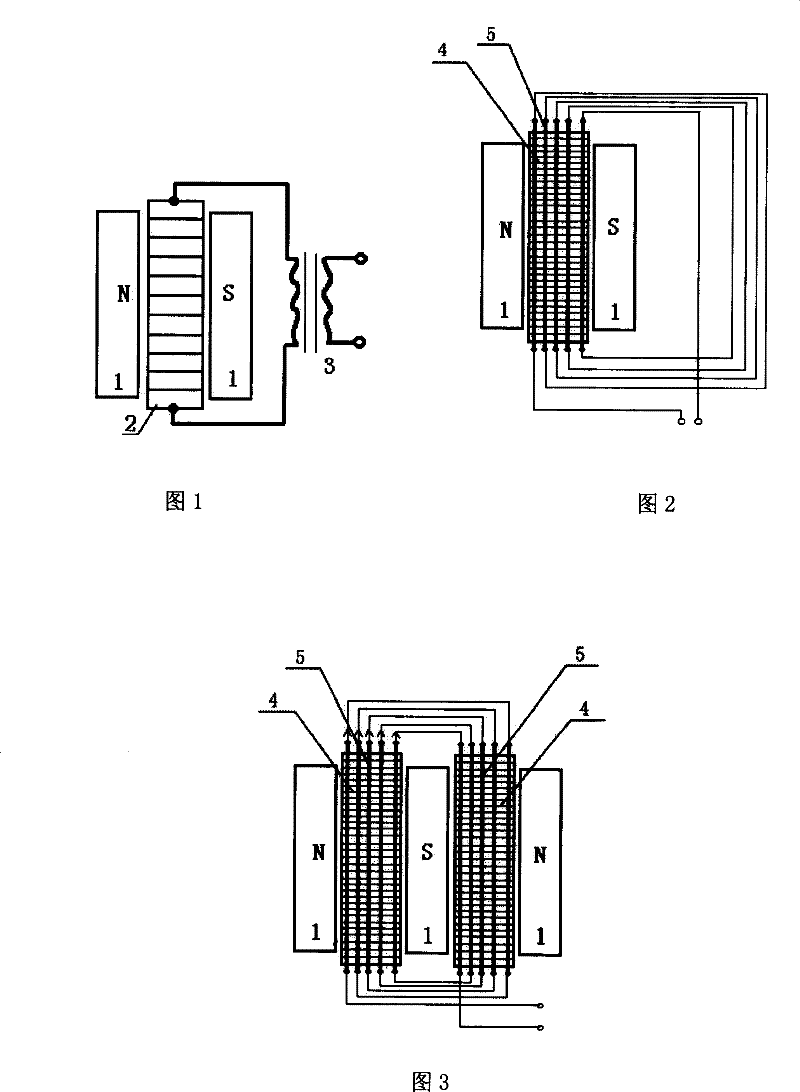

[0021] Such as figure 1 As shown, the fabric thin-ribbon sound-film loudspeaker consists of two different-named strip-shaped magnetic poles 1 juxtaposed to form a magnetic gap to form a strip-shaped permanent magnetic field, and a strip-shaped fabric thin-strip sound membrane 4 is arranged in the strip-shaped permanent magnetic field. Described strip fabric thin tape sound membrane 4 is to be 0.5 centimeters wide, and on the fabric thin tape of 10 centimeters, weaves into five enameled wires 5 (wires) of 0.06 millimeter diameter, as shown in thick solid line among the figure, and coat Cover with damping glue. Fix the strip on a 5 mm thick single-layer printed circuit board, with five copper foil lines and pads on the board, and solder the five enameled wires in the strip to the corresponding pads, so that each enameled wire forms the shape shown in the figure. The full series connection of the audio signal can generate the same phase audio current in each wire 5 when feeding ...

Embodiment 2

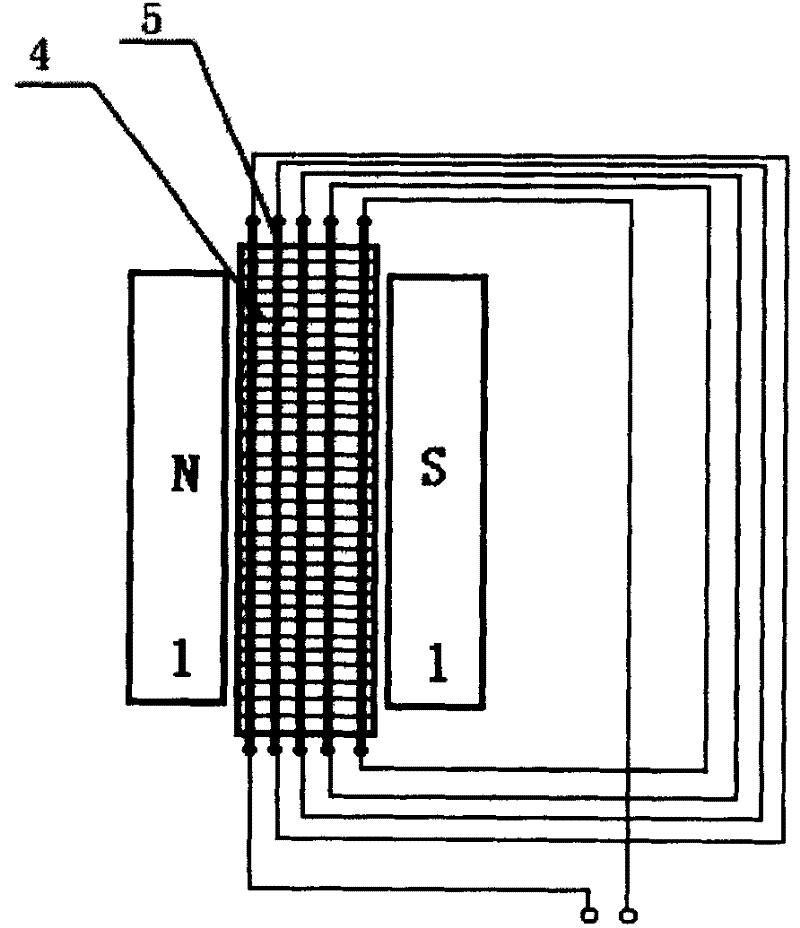

[0023] As shown in Figure 3, this embodiment is a double-band push-pull fabric thin-strip sound-film loudspeaker, which consists of three parallel strip magnetic poles 1 to form two adjacent left and right magnetic gaps, forming two left and right juxtaposed strip-shaped permanent In the magnetic field, in the two adjacent magnetic gaps, there are two thin fabric strips 4 coated with damping glue, and five wires 5 connected by external circuits are distributed in each thin fabric strip 4, forming A load of 8 ohms. The width and length of the fabric thin-strip sound membrane are similar to those of the traditional ribbon speaker, which is 0.5cm×10cm. When the fabric thin-strip sound membrane is fed with an audio signal through the power amplifier, there will be generated in the five wires of each fabric thin-strip sound membrane In-phase audio current, the current is affected by the N→S magnetic field to generate an in-phase driving force. Because the two juxtaposed strip perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com