Jig of optical element

A technology of optical components and jigs, which is applied in the direction of optical surface grinders, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of lower processing yield, inconsistent relative positions, and inconsistent shapes of optical lenses, so as to improve production efficiency and good quality. High rate, uniform distribution of glue, and consistent relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

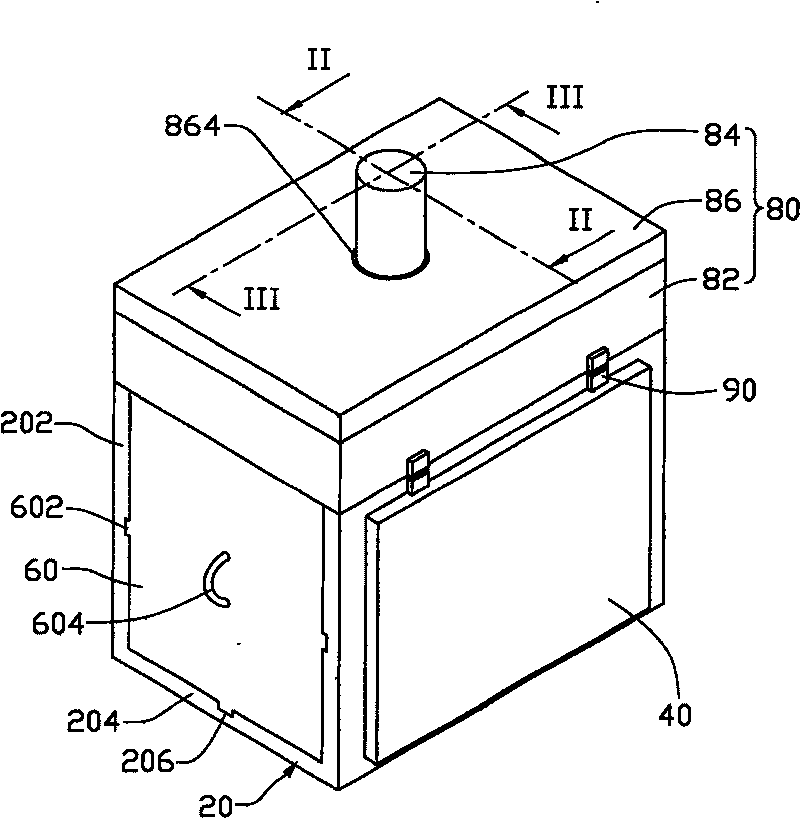

[0012] The jig for the optical element of the present invention is used for gluing multiple optical elements to facilitate the subsequent rounding process. The jig for the optical element of the present invention will be described below in terms of a preferred embodiment.

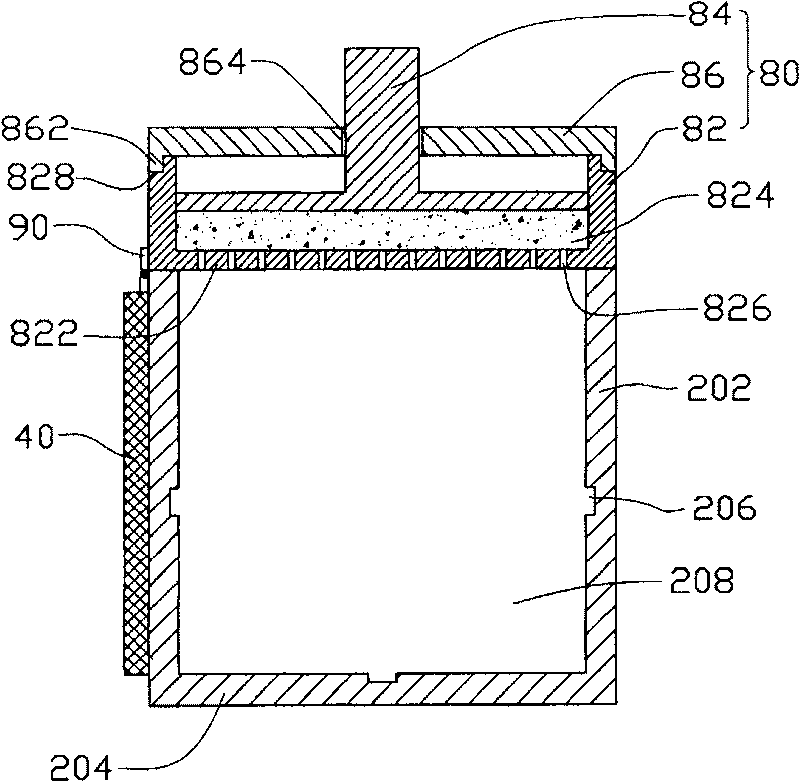

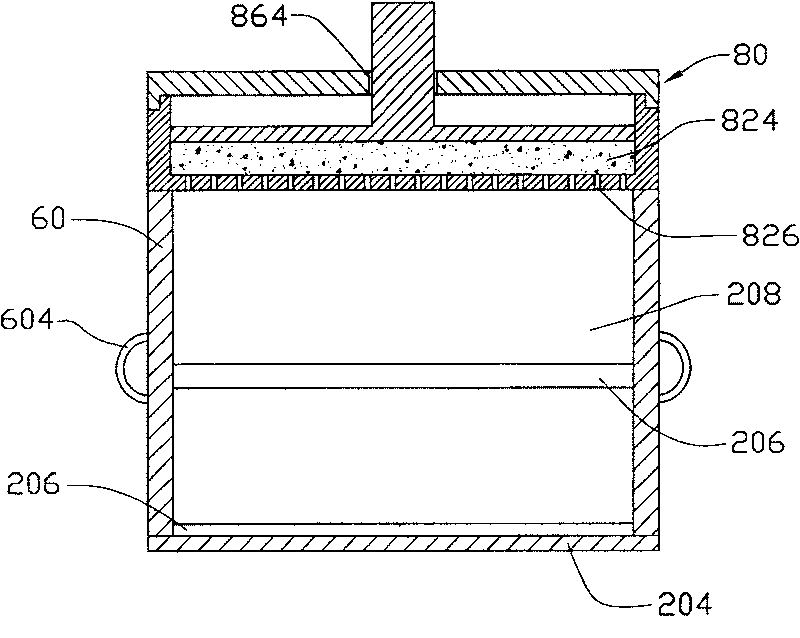

[0013] see figure 1 , the jig of the optical element includes a body 20 , a uniform cooling plate 40 , two moving plates 60 , a glue spraying device 80 and two hinges 90 .

[0014] Please also refer to figure 2 and image 3 , the body 20 is a rectangular parallelepiped frame, which is composed of two side walls 202 and a bottom plate 204 , and the two side walls 202 and the bottom plate 204 together define a receiving space 208 . The two side walls 202 are opposite to each other, and the bottom plate 204 connects the corresponding ends of the two side walls 202 . The side wall 202 and the inner middle of the bottom plate 204 respectively define a guiding chute 206 parallel to each other, and the guidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com