Hydraulic relief valve

A safety valve, hydraulic technology, applied in the field of hydraulic safety valve, can solve the problems of reduced supply function, complex structure, difficult assembly and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

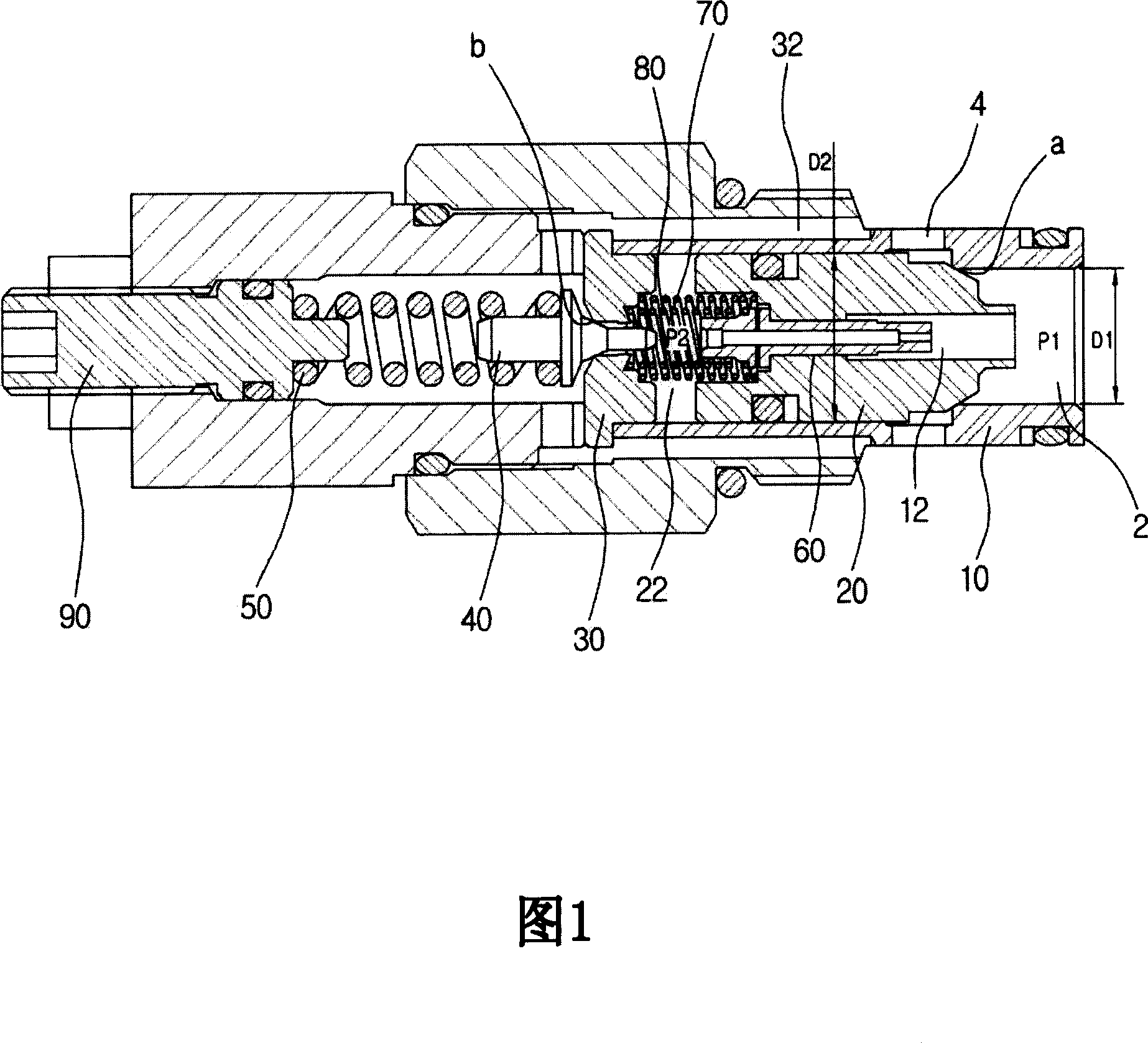

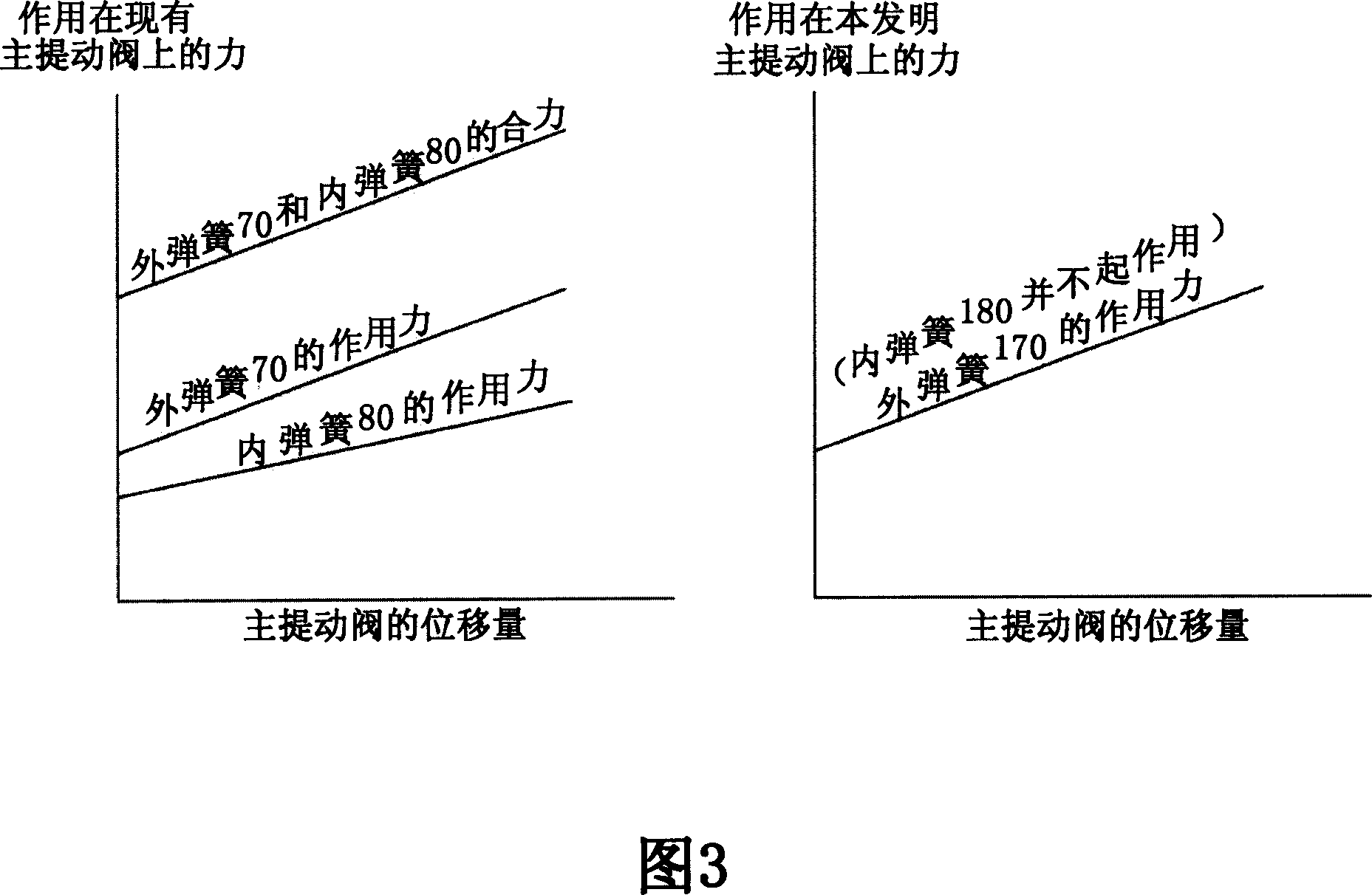

[0027] In the following, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The content defined in the specification, such as detailed structures and elements, are only specific details provided to help those of ordinary skill in the art fully understand the present invention, so the present invention is not limited to these specific details.

[0028] The structure of the hydraulic safety valve according to the present invention will now be described in detail in conjunction with preferred embodiments.

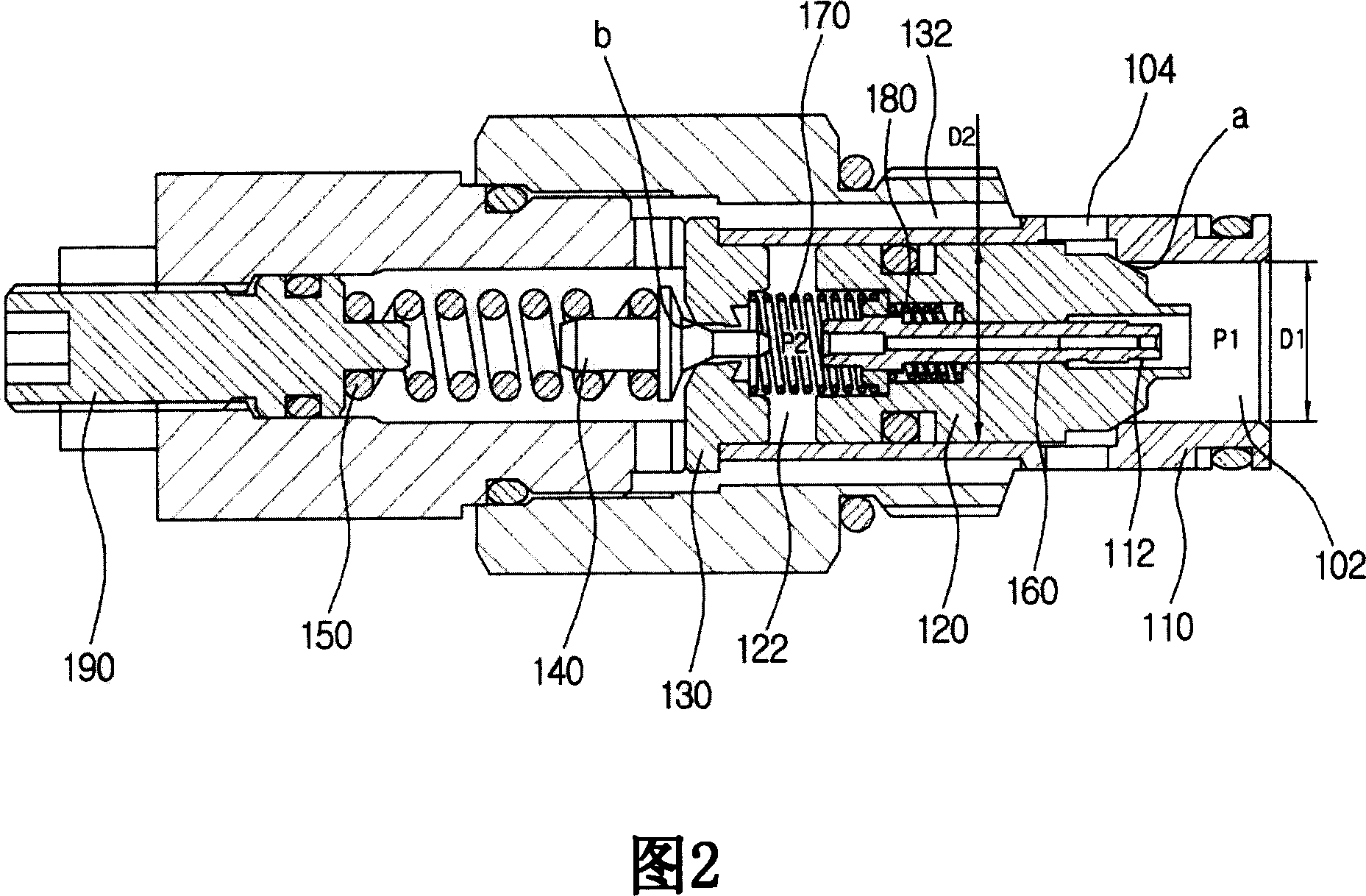

[0029] Fig. 2 is a cross-sectional view describing the structure of a hydraulic safety valve according to the present invention.

[0030] 2, the hydraulic safety valve includes: a sleeve 110 having a high-pressure flow passage 102 formed on one side of the sleeve 110 through which hydraulic fluid flowing out of the hydraulic pump P flows through the high-pressure flow passage of the high pressure P1, and A container-side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com