Housing type joint

A clamp-type pipe, arc-shaped technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, connection of packing and sealing by fluid pressure, etc. The total weight of the type pipe joint is heavy, and it is not easy to assemble the clamp type pipe joint, so as to achieve the effect of easy connection/disassembly operation, compact structure and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Description of the preferred embodiment

[0019] Hereinafter, a clamp type pipe joint according to one embodiment of the present invention is explained with reference to the drawings.

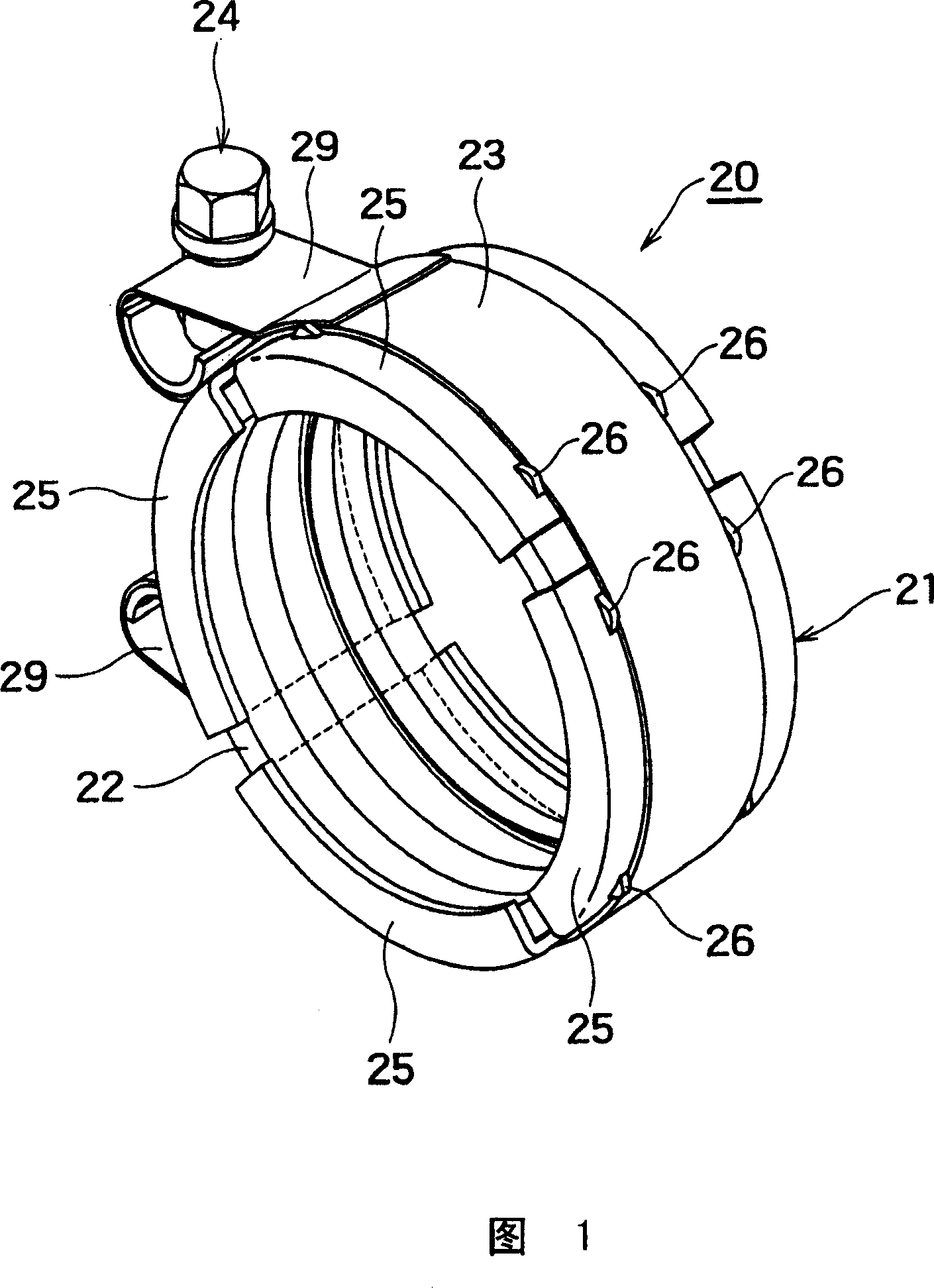

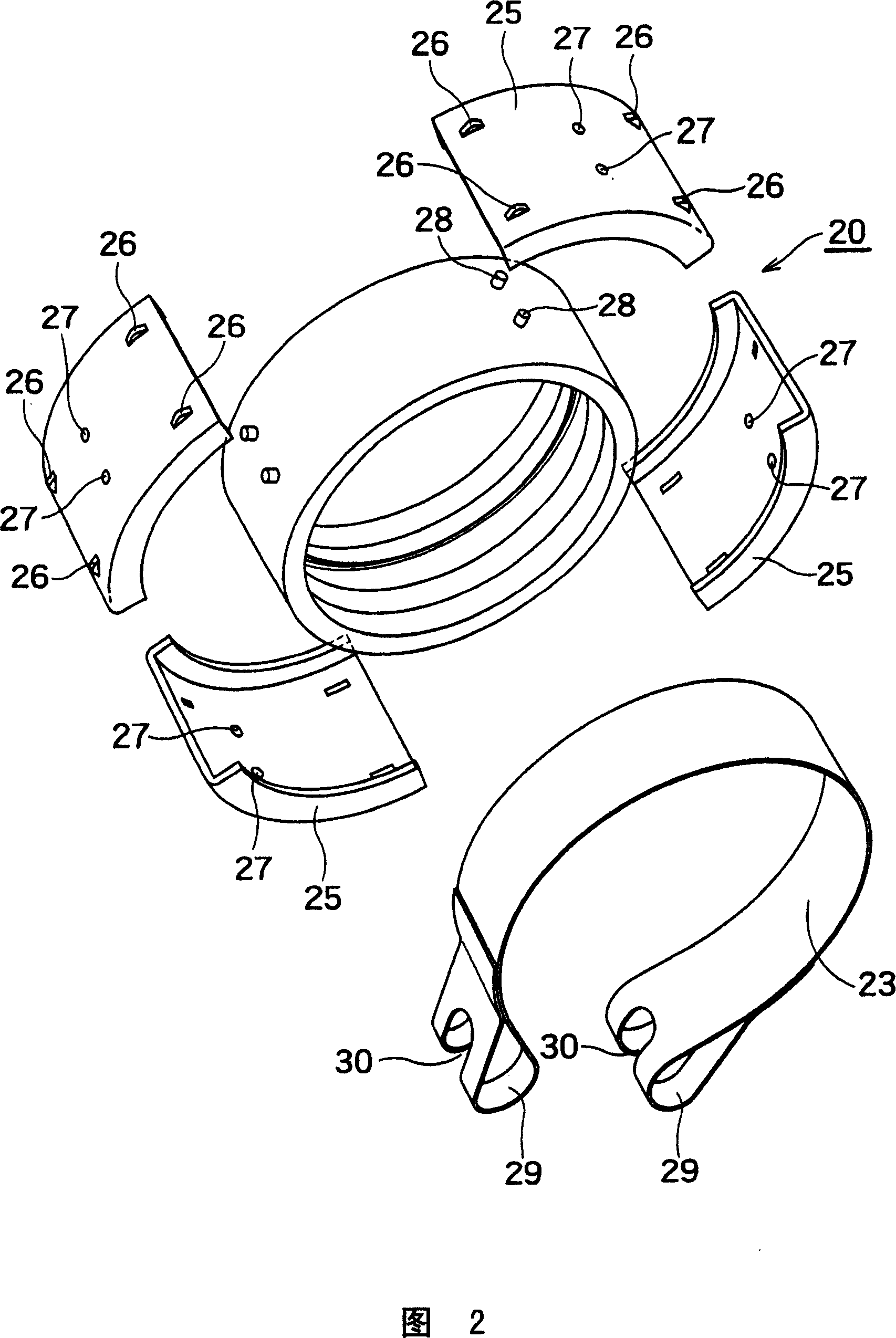

[0020] FIG. 1 is a perspective view showing a clamp type pipe joint according to one embodiment of the present invention. FIG. 2 is an exploded perspective view of the clamp type pipe joint of FIG. 1 .

[0021] As shown in Figures 1 and 2, the clamp type pipe joint 20 of the present invention includes: a casing 21, an elastic ring 22 arranged inside the casing 21, a fastening band 23 arranged around the outer surface of the casing 21, and The two ends of the fastening strap 23 are connected with fastening means 24 .

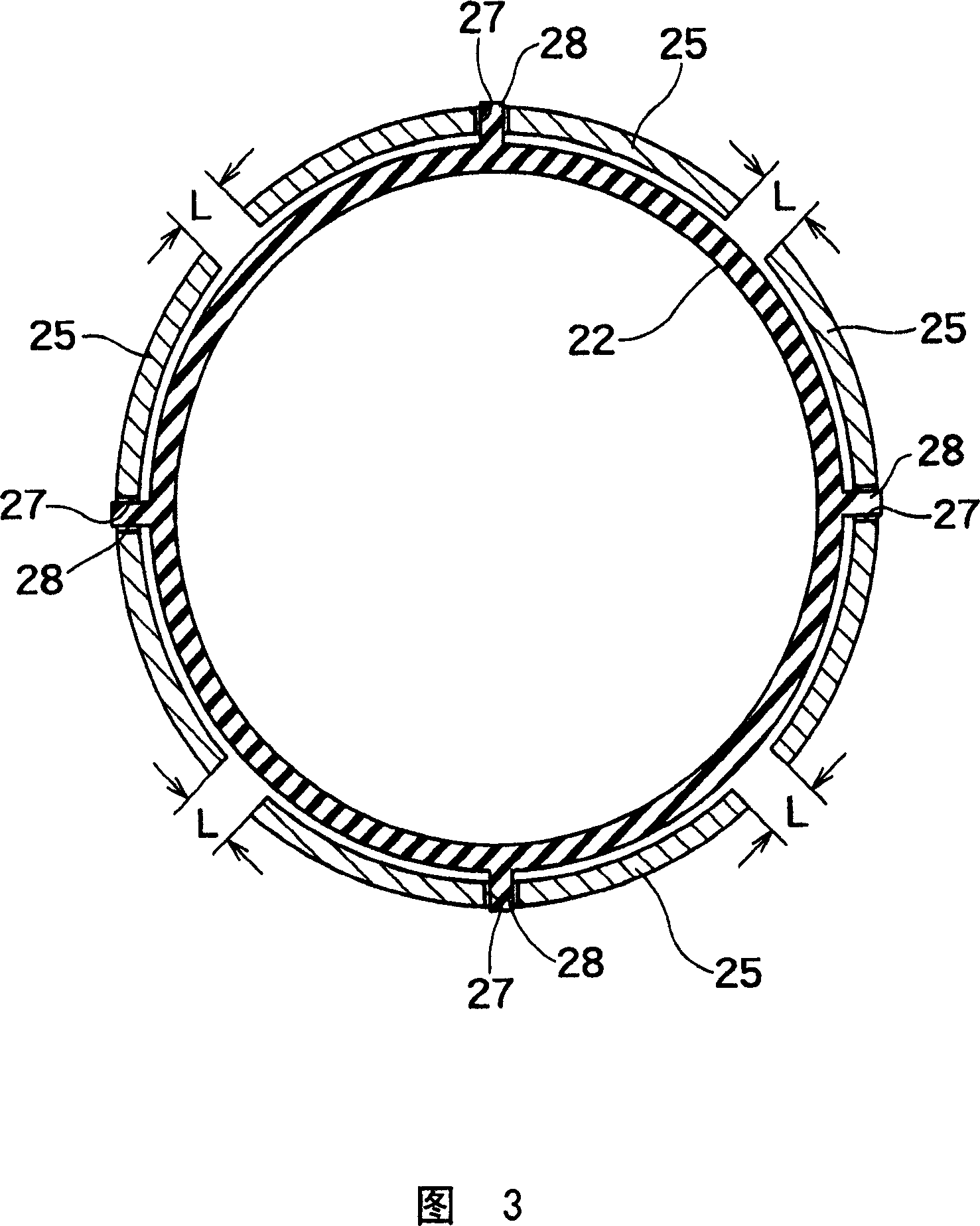

[0022] The casing 21 may be formed by arranging at least four arcuate portions 25 , 25 , 25 , 25 at intervals on or over the outer surface of the elastic ring 22 in the circumferential direction. In this embodiment, the four arcuate portions 25 have th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com