Air storing type glass tube oil gauge

A glass tube and oil measuring technology, which is applied in the direction of measuring devices, measuring capacity, volume measuring instruments/methods, etc., can solve the problems of long oil measuring process, long time for pressing the liquid level, failure to meet the measurement requirements, etc., and achieve simplified measurement Oil operation procedures, shortening the oil measuring time, and improving the effect of draining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further disclose the technical solution of the present invention, a detailed description is given below in conjunction with the accompanying drawings of the description through embodiments:

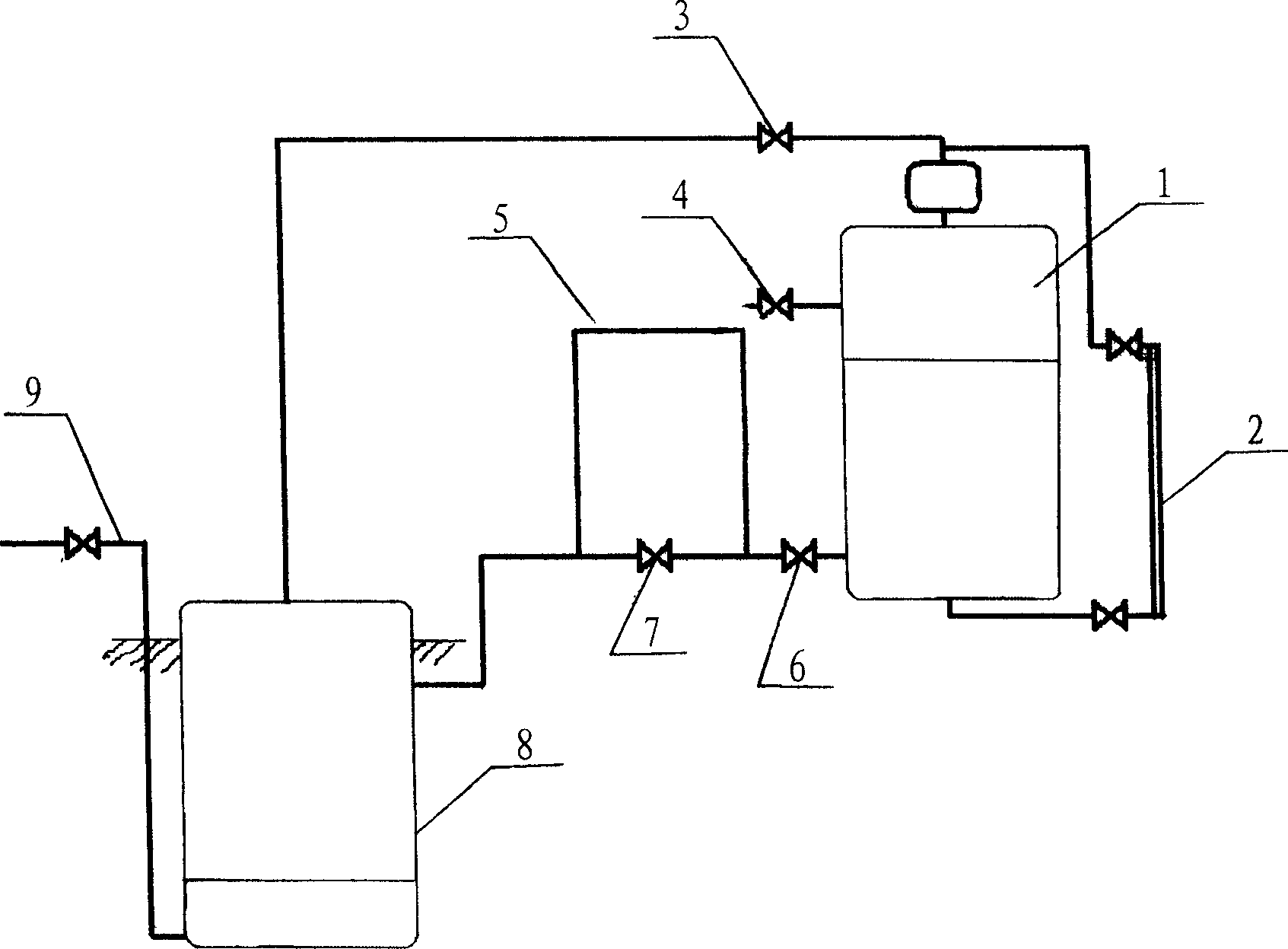

[0014] The present invention consists of a separator 1, an oil measuring glass tube 2, a gas balance valve 3, an oil and gas inlet valve 4, a U-shaped pipe 5, an oil outlet valve 6, an oil measuring valve 7, a gas storage tank 8 and an oil inlet and collection pipeline control valve 9 On the basis of the original separator metering process, a gas storage tank is added. The gas storage tank is lower than the separator and can be partially buried in the ground. The volume of the gas storage tank below the outlet height of the separator is equal to the volume of the separator. There is a balance pipe on the top of the gas storage tank that communicates with the gas balance valve, and the lead-out pipeline from the bottom of the gas storage tank is connected with the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com