Throwing mixing homogenizing device

A uniform mixing and interlocking technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of lack of direct impact force, time-consuming, etc., and achieve the effect of rapid dispersion and homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

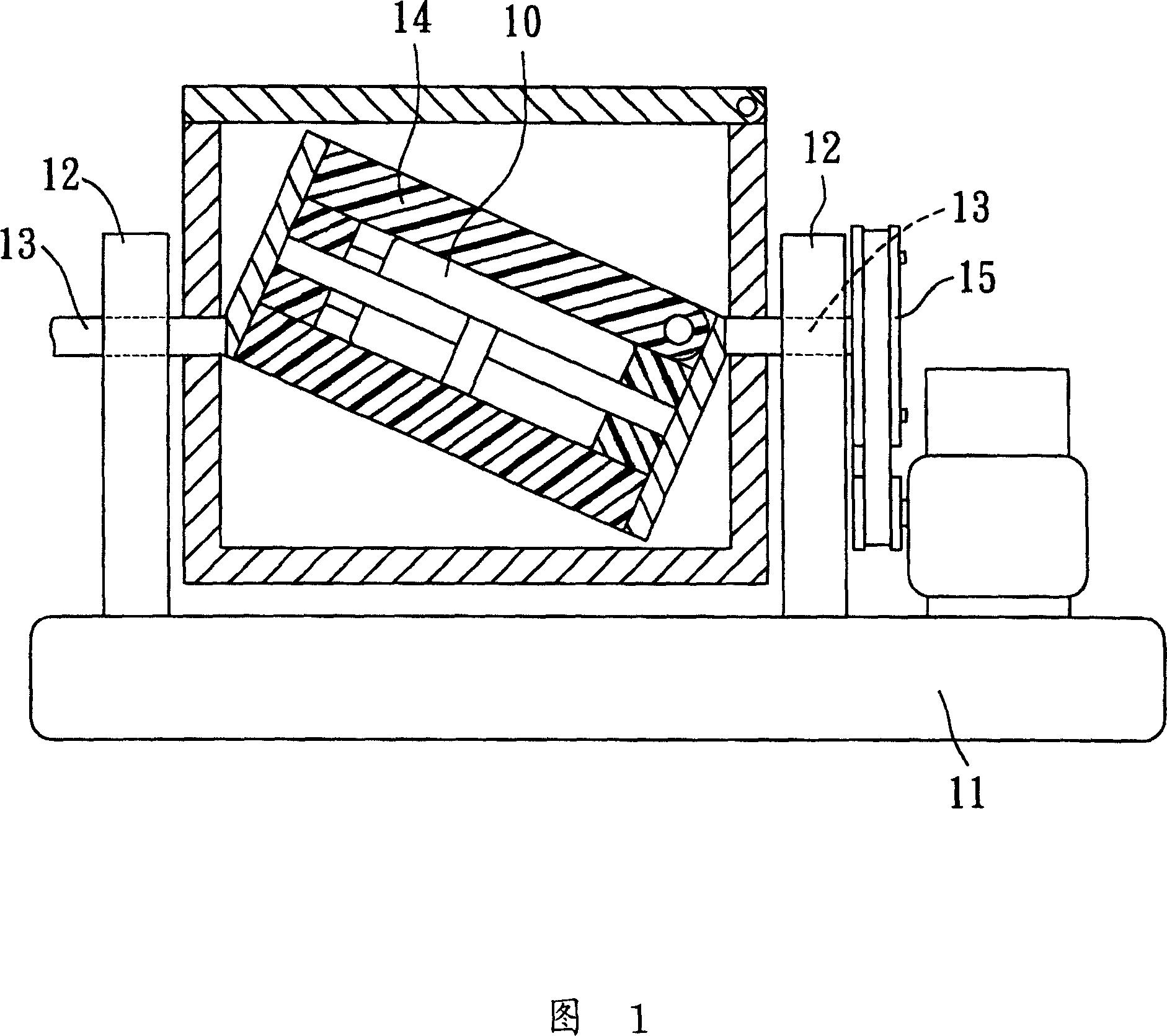

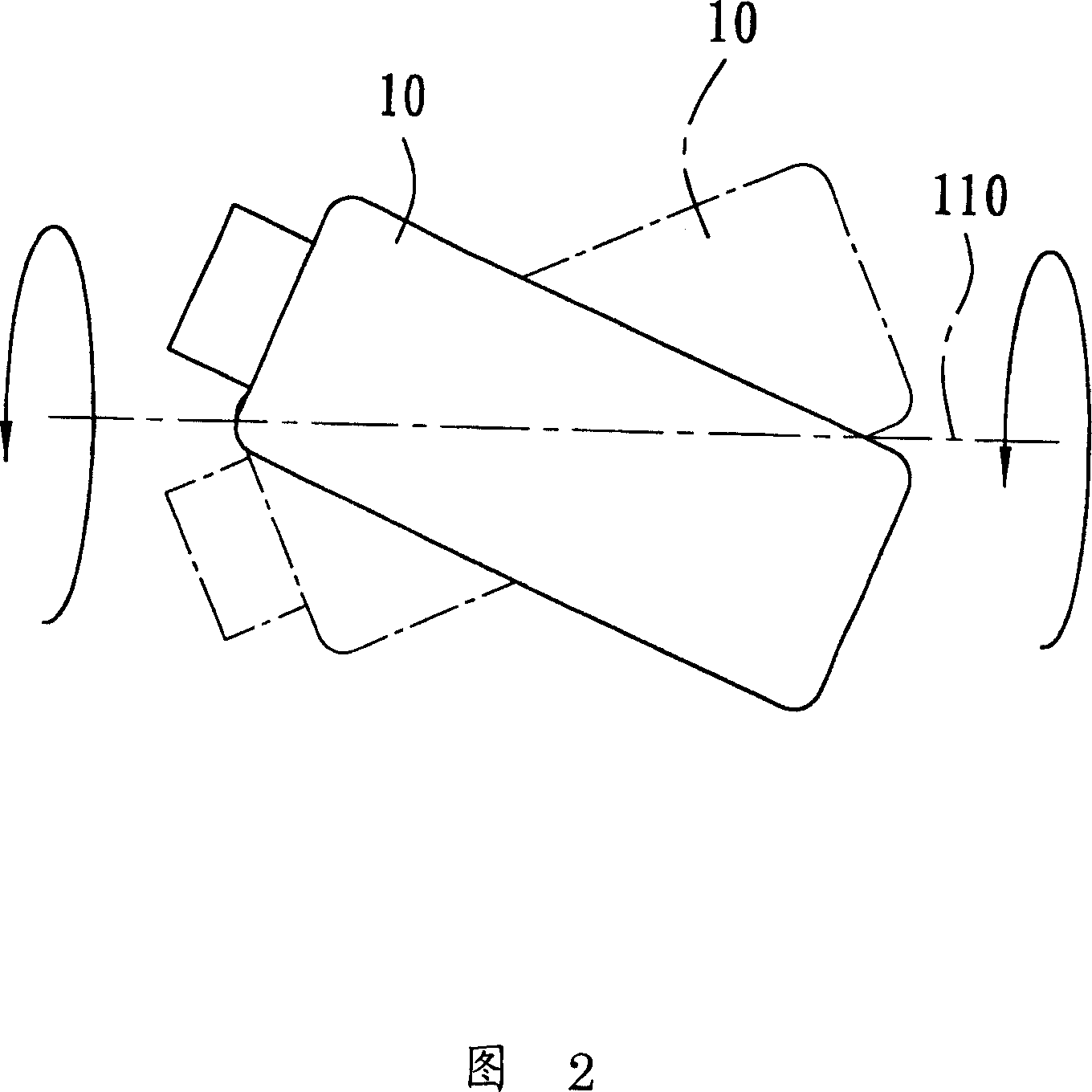

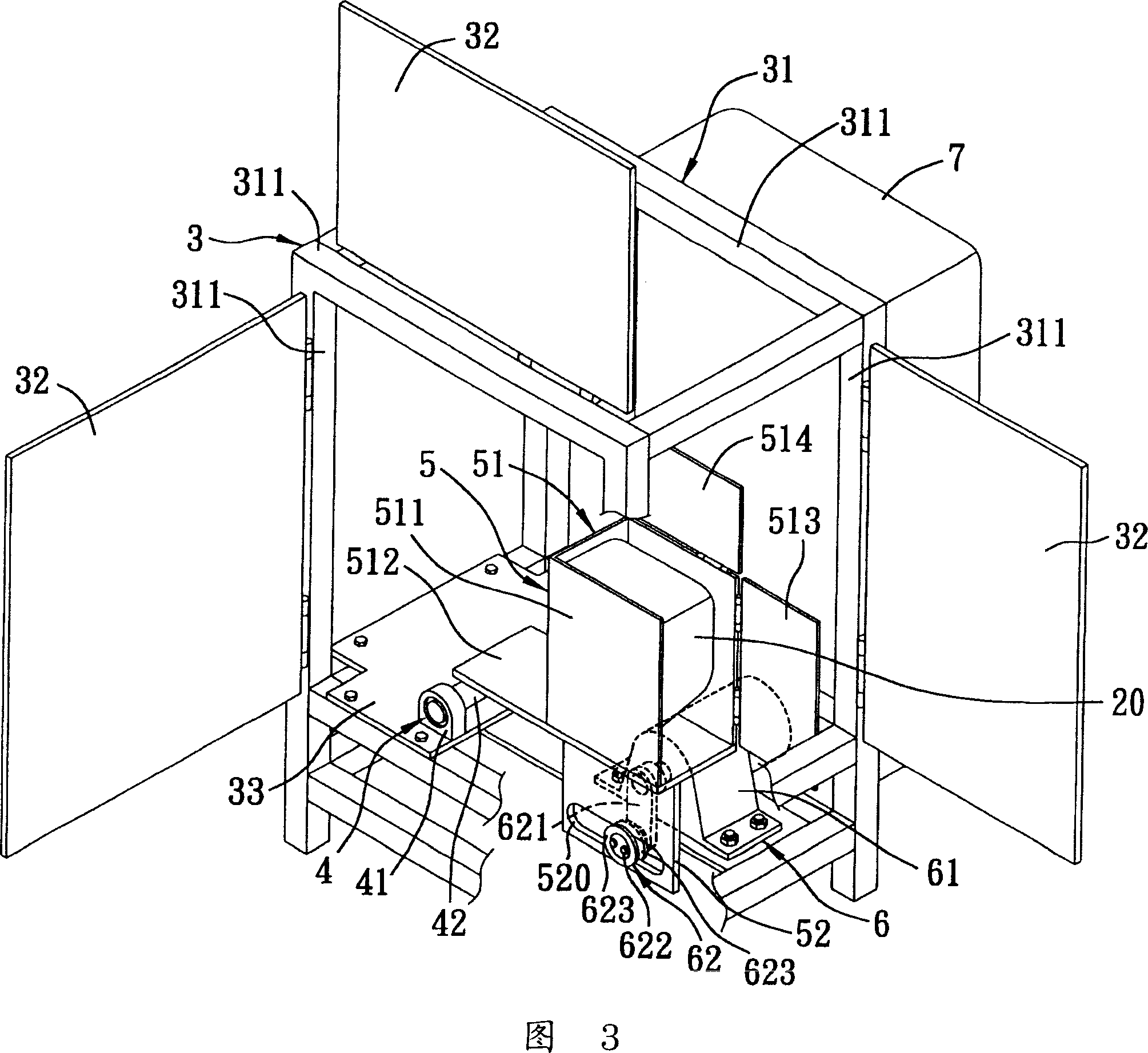

[0023] The shaking-type mixing uniform device of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] As shown in Figures 3 to 5, the embodiment of the shaking type mixing uniform device of the present invention includes: a hollow shell base 3, and a pivoting unit 4, a swinging box unit 5, And a drive unit 6.

[0025] The shell seat 3 includes a hollow cuboid seat body 31 assembled from a plurality of frame rods 311, a plurality of openable door panels 32 assembled around and on the top side of the seat body 31, and a horizontally assembled seat body. Substrate 33 in 31.

[0026] The pivot unit 4 includes two left and right bearing seats 41 spaced apart from each other at the front edge of the top surface of the base plate 33 , and a pivot shaft 42 rotatably pivoted between the bearing seats 41 .

[0027] The swing box unit 5 can be connected with the pivot unit 4 and assembled on the side of the pivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com