Treatment method of bipolar substrate coating of lead-acid battery

A treatment method and technology for lead-acid batteries, applied in battery electrodes, bipolar electrodes, secondary batteries, etc., can solve problems such as instability, and achieve the effect of improving electrical conductivity, high electrical conductivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

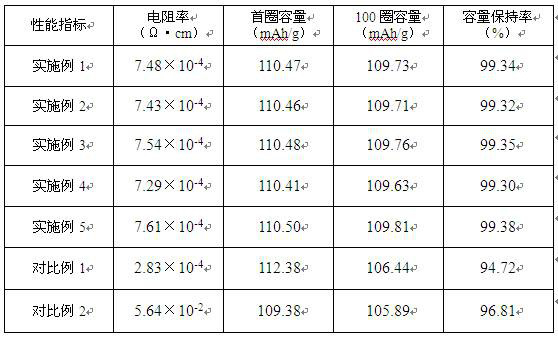

Examples

Embodiment 1

[0035] (1) Use diamond powder to grind both sides of the Ti-6Al-4V alloy substrate with an average thickness of 2.5mm until a large number of scratches visible to the naked eye appear on the surface of the substrate, and then wash with absolute ethanol to remove the oil phase impurities on the surface, Vacuum drying to obtain the substrate material;

[0036] (2) Place the obtained substrate material in a CVD vacuum deposition chamber, control the vacuum degree of the furnace body at 0.5kPa, and then pass a mixed gas of hydrogen, argon, methane, and borane into the furnace body for plasma vapor deposition , in the mixed gas, the volume ratio of hydrogen, argon, methane, and borane is 400:100:40:15, the gas source flow rate of the mixed gas is controlled at 450 sccm, the deposition temperature is controlled at 850°C, and the deposition is 6h, and then the methane and Borane gas source, and at the same time turn off the deposition equipment, so that the substrate is rapidly coole...

Embodiment 2

[0039] (1) Use diamond powder to grind both sides of the Ti-6Al-4V alloy substrate with an average thickness of 2.2 mm until a large number of scratches visible to the naked eye appear on the surface of the substrate, and then wash with absolute ethanol to remove the oil phase impurities on the surface, Vacuum drying to obtain the substrate material;

[0040] (2) Place the obtained substrate material in a CVD vacuum deposition chamber, control the vacuum degree of the furnace body at 0.3Pa, and then pass a mixed gas of hydrogen, argon, methane, and borane into the furnace body for plasma vapor deposition , in the mixed gas, the volume ratio of hydrogen, argon, methane, and borane is 400:100:35:12, the gas source flow rate of the mixed gas is controlled at 420 sccm, the deposition temperature is controlled at 820°C, and the deposition is 7h, and then the methane and Borane gas source, and at the same time turn off the deposition equipment, so that the substrate is rapidly coole...

Embodiment 3

[0043] (1) Use diamond powder to grind both sides of the Ti-6Al-4V alloy substrate with an average thickness of 2.8mm until a large number of scratches visible to the naked eye appear on the surface of the substrate, and then wash with absolute ethanol to remove the oil phase impurities on the surface, Vacuum drying to obtain the substrate material;

[0044] (2) Place the obtained substrate material in a CVD vacuum deposition chamber, control the vacuum degree of the furnace body at 0.8kPa, and then pass a mixed gas of hydrogen, argon, methane, and borane into the furnace body for plasma vapor deposition , in the mixed gas, the volume ratio of hydrogen, argon, methane, and borane is 400:100:45:18, the flow rate of the gas source of the mixed gas is controlled at 480 sccm, the deposition temperature is controlled at 880 ° C, and the deposition is 5h. After that, the methane and Borane gas source, and at the same time turn off the deposition equipment, so that the substrate is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com